Ceramic capacitance sensor for ultra-high frequency on-line monitoring local high-voltage discharge

A ceramic capacitor and partial discharge technology, which is applied in the field of on-line monitoring of the insulation state of large-scale power equipment, and in the field of sensors, can solve the problems of reduced sensitivity and reliability of measurement results, pulse waveform distortion, and unsuitable neutral point, etc., and achieves compact structure and durable The effect of high electric strength and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor.

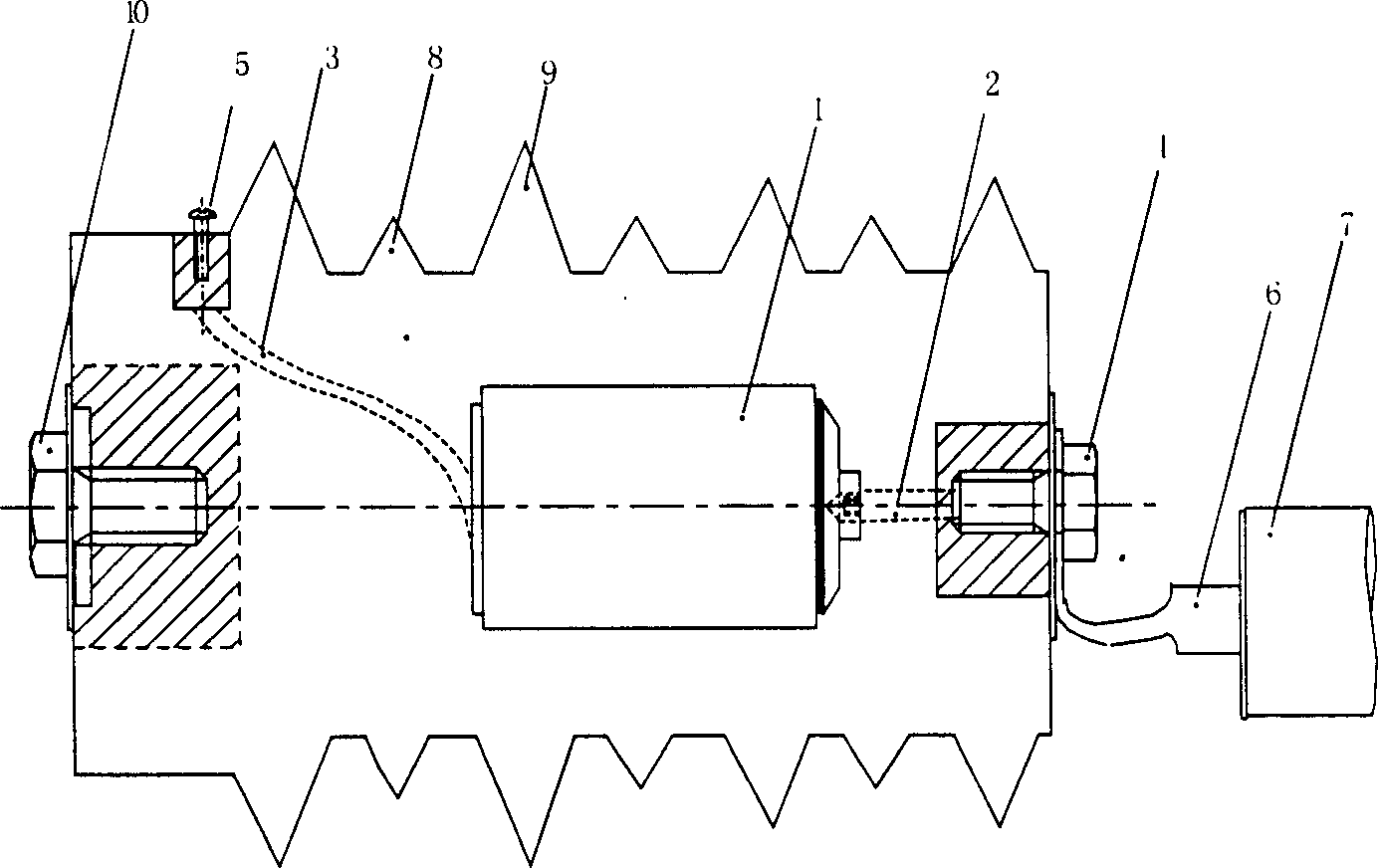

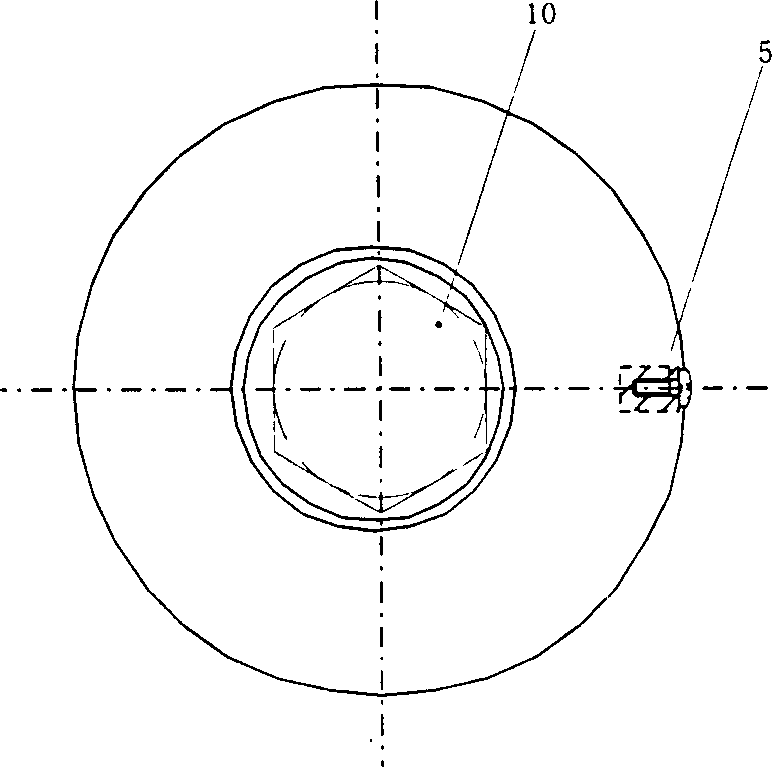

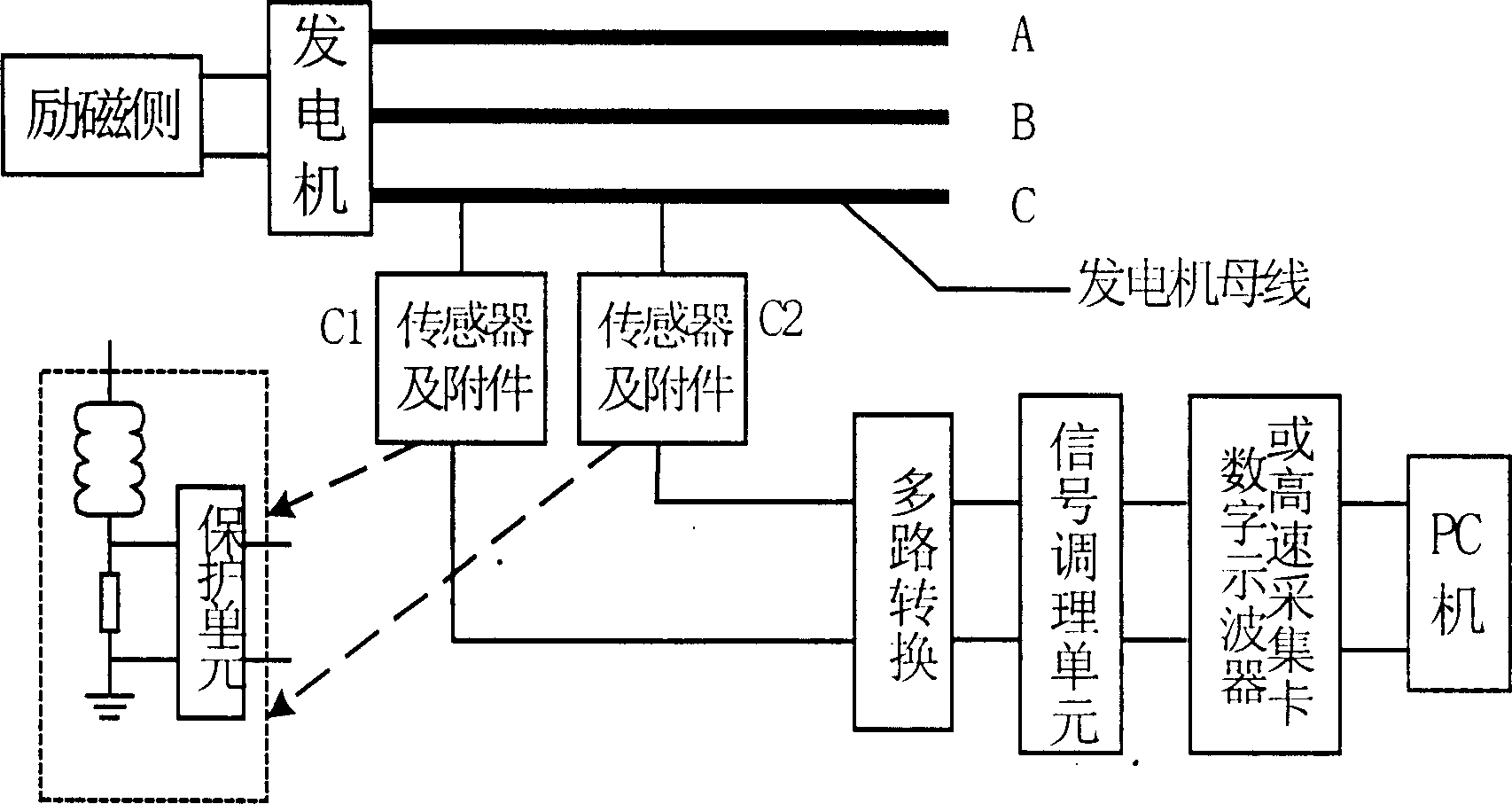

[0031] see Figure 1~2 , figure 1 It is a side sectional view of the ceramic capacitive sensor of the present invention; the symbols in the figure respectively represent: 1-ceramic capacitor core, 2-represents the conductive metal rod of the upper electrode, 3-represents the conductive metal strip of the lower electrode, 4-represents the cable fastening bolt, 5-represents the lower electrode lead fixing screw, 6-represents the connecting cable conductor, 7-bus connection cable, 8-small epoxy resin umbrella group, 9-epoxy resin large umbrella group, 10-fixing bolt; figure 2 yes figure 1 The left view of ; the symbols in the figure represent respectively: 5-lower electrode lead wire fixing screw, 10-fixing bolt;

[0032] It can be seen from the structural di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com