Doping method used in vertical pulling silicon single crystal preparation and its installation

A technology of Czochralski silicon and single crystal, which is applied in the direction of single crystal growth, chemical instruments and methods, self-melt liquid pulling method, etc., to achieve the effects of improving doping efficiency, easy availability of raw materials and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

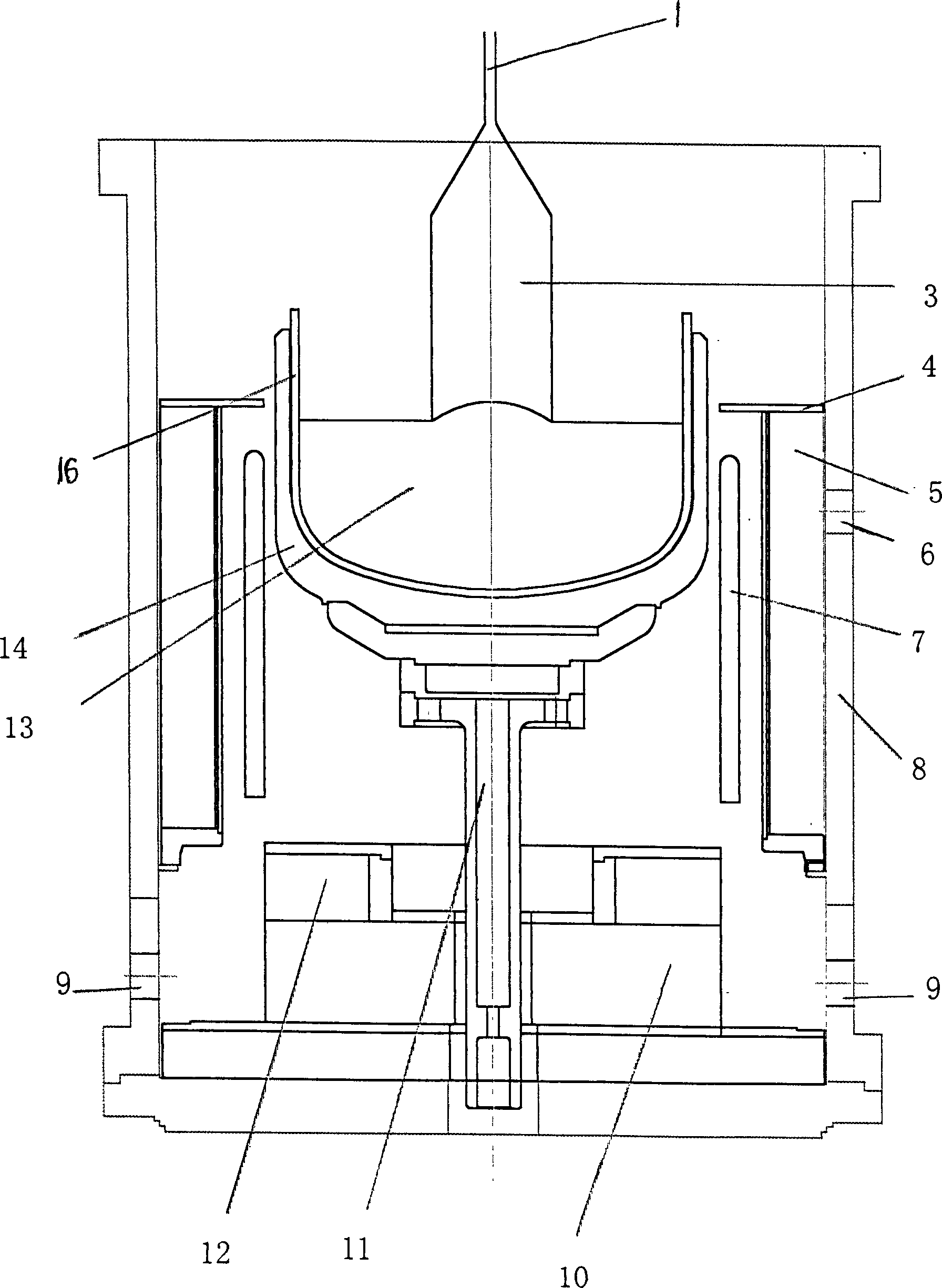

Method used

Image

Examples

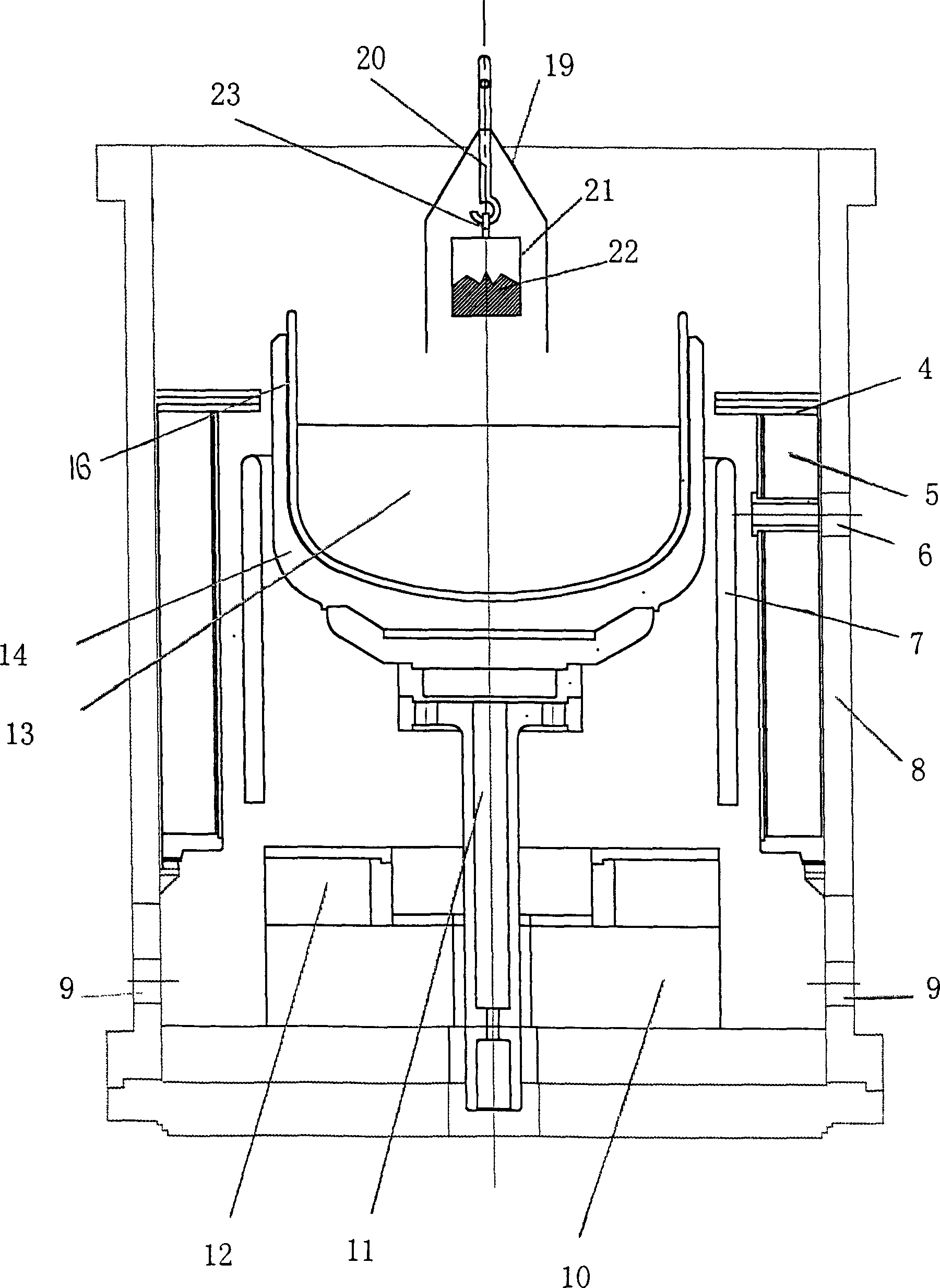

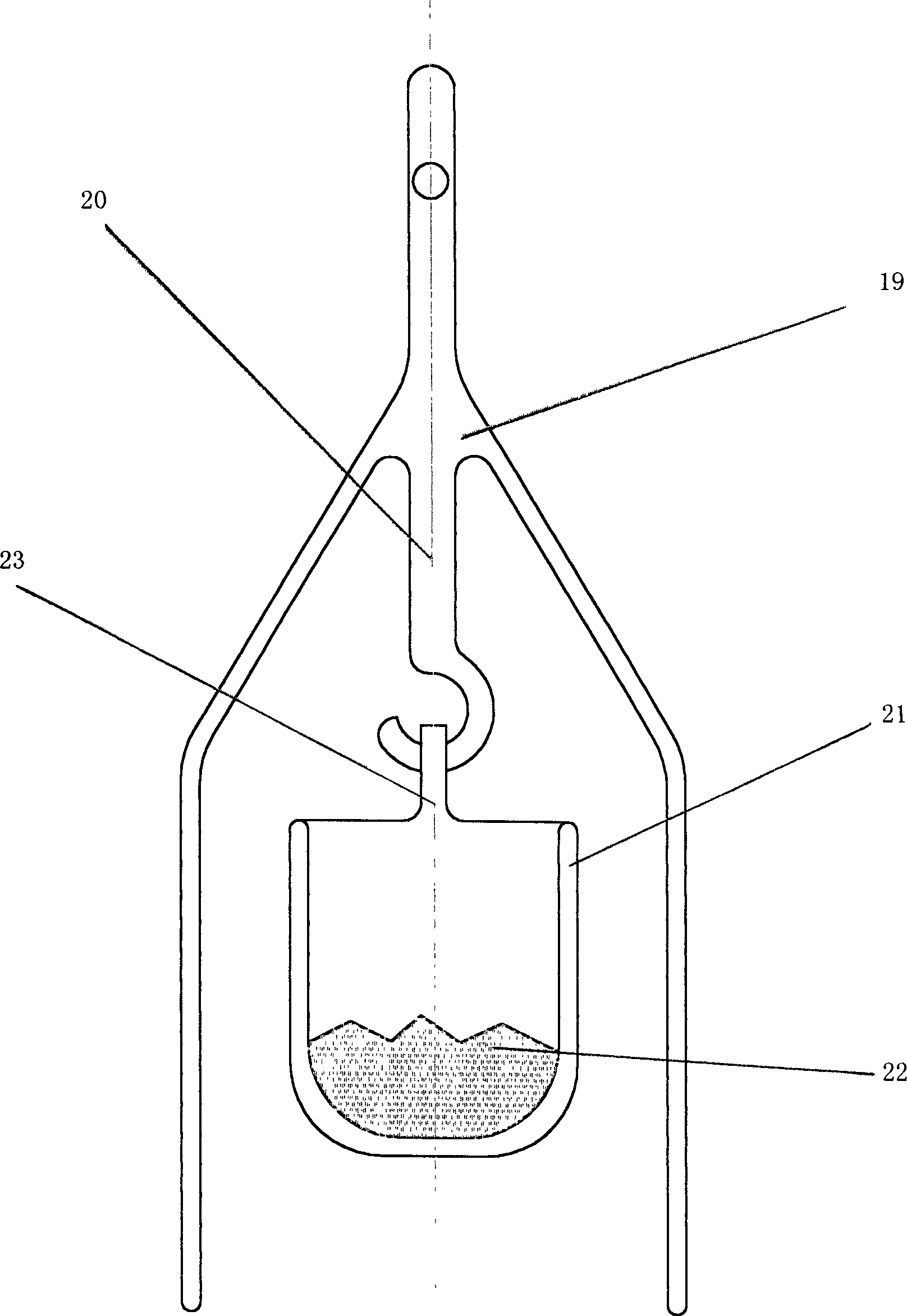

Embodiment 1

[0035] Place 4.56 grams of semiconductor-grade phosphorus (P), the element to be doped, in the inner cylinder 21 of the doping device, hang the doping device with the inner cylinder 21 in the crystal pulling chamber, and evacuate to 6.5Pa. The pulling chamber and the crystal growth chamber are filled with argon, so that the pressure of the argon is 2.66×10 3 Pa, 30 kg of polysilicon as raw material is placed in a quartz crucible to melt the polysilicon. After the polysilicon is melted, the temperature of the molten silicon is stabilized at 1400°C. The doping device of the inner cylinder of impurity P (phosphorus) descends to the liquid level of the polysilicon melt at a speed of 100 mm / min, so that the distance between the lower port surface of the bell jar 19 and the molten polysilicon liquid level is 100 mm. After seeing from the window that the doping element P is completely volatilized (about 5 minutes), the quartz crucible continues to rotate for 20 minutes under the cond...

Embodiment 2

[0039] The operating method and equipment are the same as in Example 1, except that the phosphorus in the inner cylinder is 66.36 grams, and the vacuum is evacuated to 11Pa, and the pressure of the argon gas in the crystal pulling cabin and crystal growth chamber is 1.3×10 4 Pa, the amount of raw polysilicon is 60 kg, the temperature of the melted silicon is stable at 1422C, the rotation speed of the quartz crucible is 6 rpm, and the doping device with the inner cylinder containing the doping element P is at 150mm / min The speed drops to the liquid level of the polysilicon melt, so that the lower port surface of the bell jar 19 is 200 mm away from the molten polysilicon liquid level. After seeing the phosphorus volatilize completely from the window (about 47 minutes), the quartz crucible rotates at a rotational speed Continue to rotate at 6 rpm for 80 minutes. After closing the door of the crystal lifting cabin, keep the air pressure in the body lifting cabin at 1.3×10 4 Pa, op...

Embodiment 3

[0042] The operation method and equipment are basically the same as in Example 1, except that the doping element in the inner cylinder is semiconductor-grade antimony Sb, 112.04 grams, vacuumed to 7Pa, and the pressure of argon in the crystal pulling chamber and crystal growth chamber is 2.0× 10 3 Pa, the amount of raw polysilicon is 60 kg, the temperature of molten silicon is stable at 1450 ° C, the rotation speed of the quartz crucible is 10 rpm, and the doping device with the inner cylinder containing the doping element Sb is at 500 mm / min The speed is lowered to the liquid level of the polysilicon melt, so that the distance between the lower port surface of the bell jar 19 and the polysilicon liquid level of melting is 5 mm. After the Sb is completely volatilized from the window, (about 50 minutes), the quartz crucible Rotate at a rotation rate of 10 rpm and continue to rotate for 120 minutes, close the door of the crystal pulling cabin, and keep the air pressure in the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com