Method of preparing chitin oligosaccharide by coupled enzymolysis and its equipment

A technology of chitosan oligosaccharides and enzyme coupling, applied in the direction of fermentation, etc., can solve the problems of lower equipment utilization, clogging of membrane separation reactors, and large index fluctuations, so as to improve utilization, increase yield, and reduce clogging problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

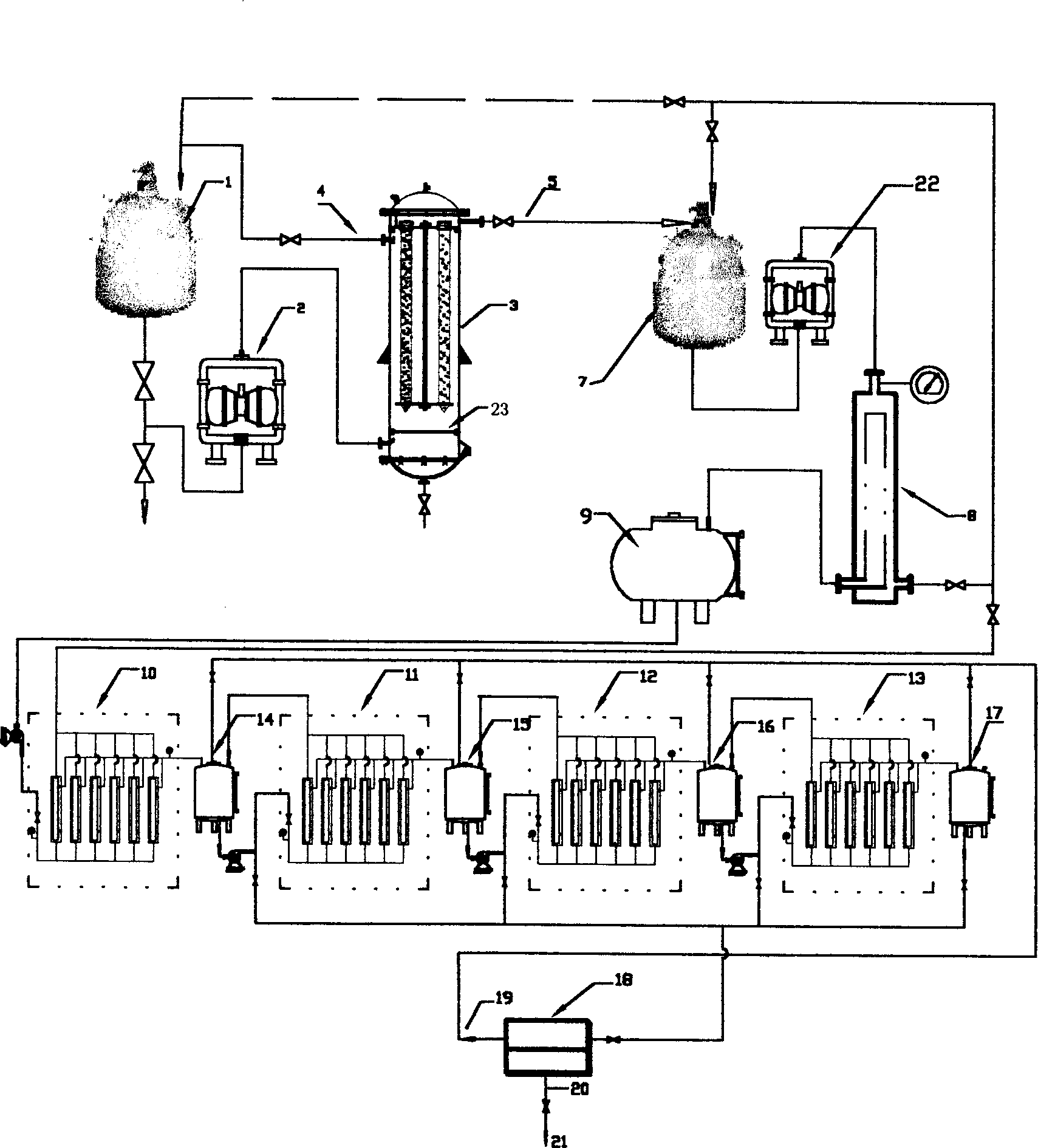

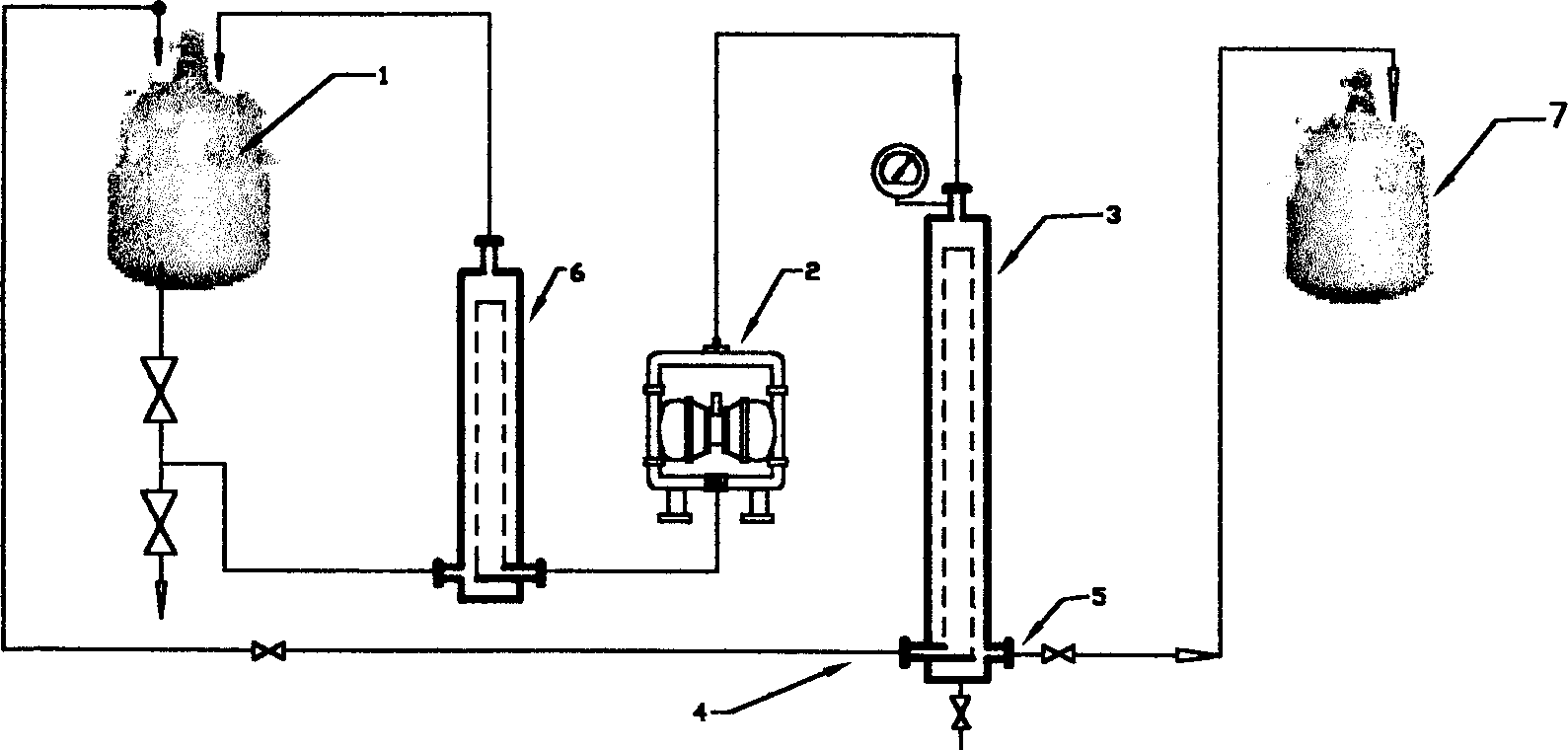

[0037] Example 1: Select hemicellulose complex enzyme as the chitosan degrading enzyme, the best environment for enzymatic degradation is: pH=5.3, temperature t=47°C, enzyme concentration 0.1%, substrate concentration 10%; according to the above Technical parameters, add 1000L (liter) of pure water into the dissolution-enzyme degradation reaction kettle 1, then add a certain amount of acetic acid, adjust the pH value of the solution in the kettle to 5.3, and the temperature of the reaction liquid in the kettle is at 47°C±1°C , then add 100kg chitosan, stir to dissolve, after 1 hour, check the pH value of the feed liquid in the kettle, if there is any change, you need to add the corresponding acid or alkali to adjust, after passing the test, disperse 1000mL of the prepared biological enzyme Add it into the kettle, and under the condition of maintaining the temperature of the reaction solution in the kettle, stir and degrade it. After 2 hours, the viscosity of the reaction soluti...

Embodiment 2

[0042] Embodiment 2: adopt the equipment condition of embodiment 1, select for use papain, pectinase, cellulase and lysozyme to be mixed with a certain amount of compound enzyme by a certain proportion, through testing, obtain the hydrolysis optimal environment of this compound enzyme The parameters are: pH=4.5, temperature t=42°C; the enzyme concentration in the reaction solution is 2%, and the substrate concentration is 3-4.5%;

[0043] According to the technical parameters required above, add 1000L of pure water into the dissolution-enzyme degradation reaction kettle 1, and then add a certain amount of acetic acid to adjust the pH value of the solution in the kettle to 4.5, and the temperature of the reaction liquid in the kettle is 42 ° C ± 1 ℃, add 30kg of chitosan, stir to dissolve, and prepare a reaction solution with a substrate concentration of 3% and a pH of 4.5. After 1 to 2 hours, check the pH value of the feed liquid in the kettle. If there is any change, you need...

Embodiment 3

[0046] Example 3: Using the equipment conditions of Example 1, this example selects hemicellulose complex enzyme as the chitosan degrading enzyme, and the best environment for enzymatic degradation is: pH=5.3, temperature t=45°C; The enzyme concentration is 0.2%, and the substrate concentration prepared according to the amount of material is 5%;

[0047] According to the technical parameters required above, add 1000L of pure water into the dissolution-enzyme degradation reaction kettle 1, and then add a certain amount of acetic acid to adjust the pH value of the solution in the kettle to 5.3, and the temperature of the reaction liquid in the kettle is 45 ° C ± 1 ℃, add 50kg of chitosan, stir to dissolve, and prepare a reaction solution with a substrate concentration of 5% and a pH of 5.3. After 0.5 hours, check the pH value of the feed liquid in the kettle. If there is any change, you need to add the corresponding acid or alkali to adjust it. Under the condition of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com