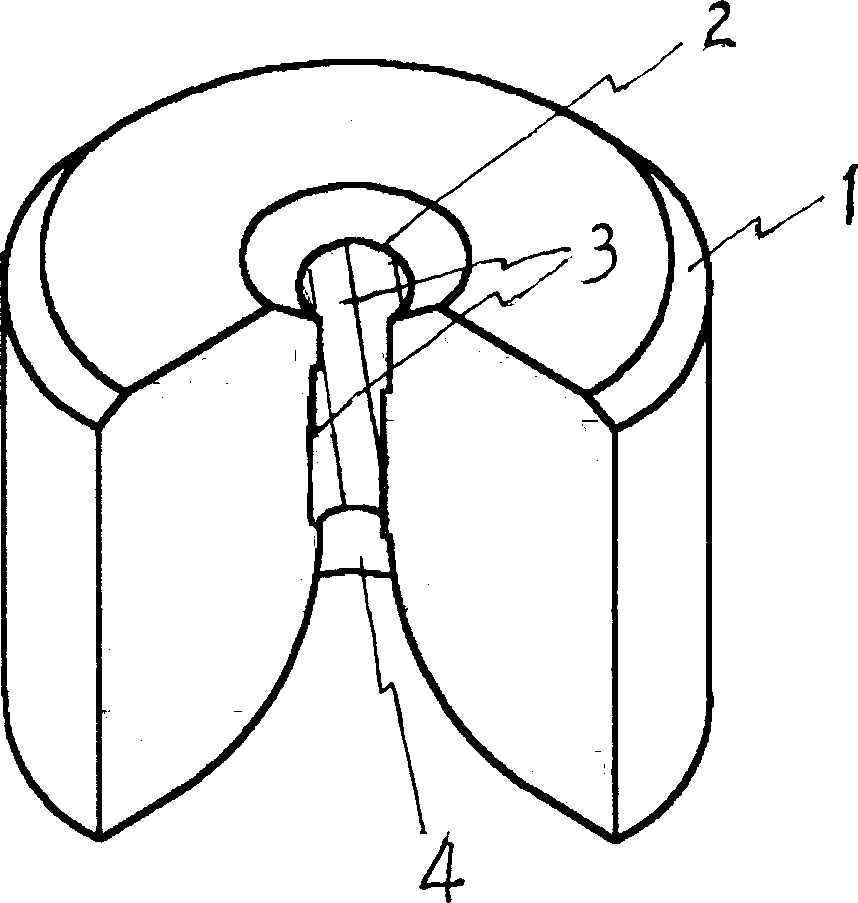

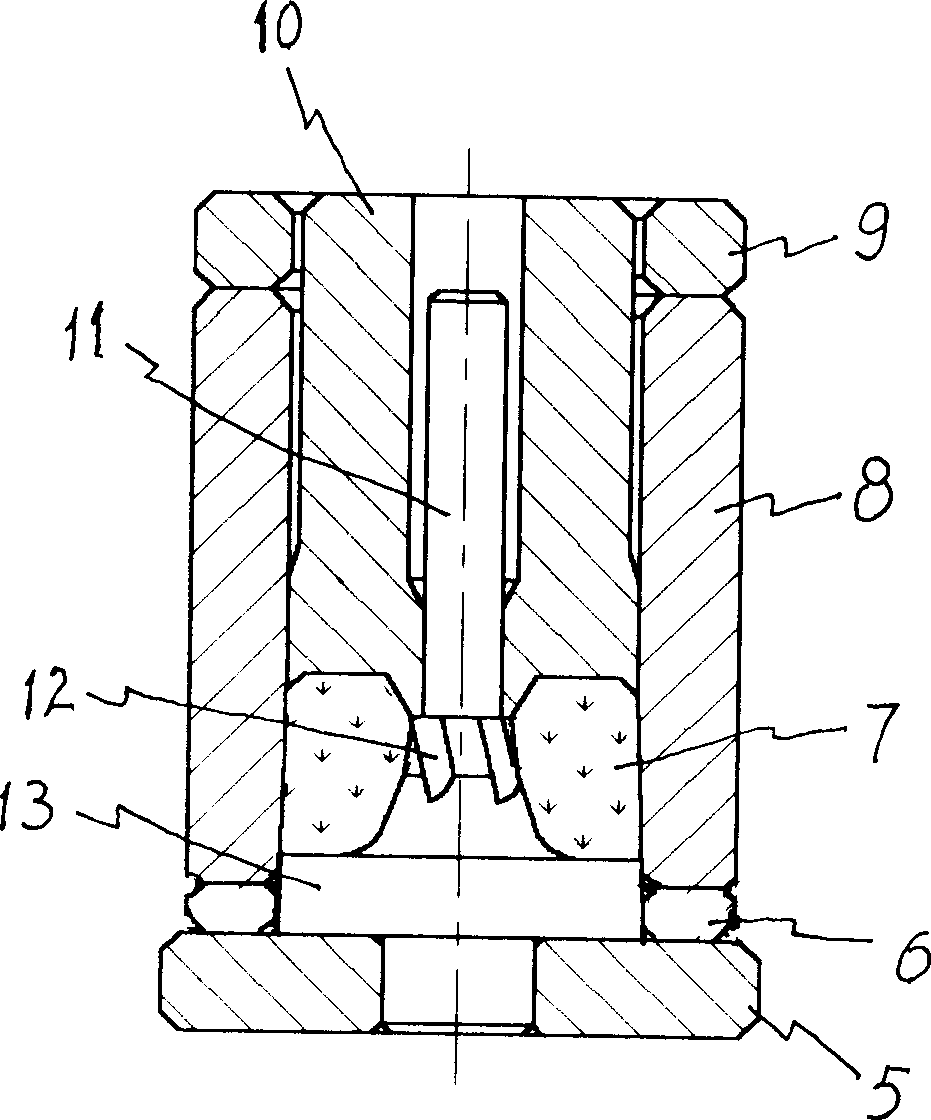

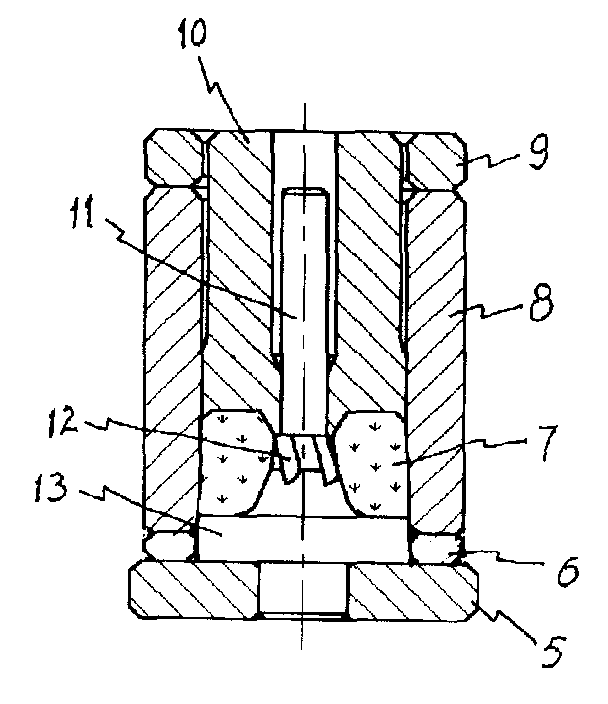

Production and mould for machining spiral mould for ribbed steel bars

A production method and ribbed steel bar technology, applied in the direction of wire drawing dies, etc., can solve the problems of not being able to meet batch and industrial production, complicated processing technology, and low production efficiency, and achieve stable and stable product quality, which is beneficial to The effect of batch and industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In this embodiment, the spiral die head (material is YG8X) for drawing Φ7mm reinforced steel bar is taken as an example:

[0019] A. Material preparation: 93 kg of WC powder (Fischer particle size 1.0-4.0 μm) containing 93.6% of W (tungsten) and 7 kg of cobalt-containing 98.8% cobalt powder (Fischer particle size 1.5-4.0 μm) were wet-milled and mixed for 40 hours. It is ethanol with a purity ≥ 95.5%; it is filtered through a sieve with a pore size of 45 μm and precipitated for 4 hours, and then sent to a dryer with a vapor pressure of 0.05 Mpa for drying; the dried powder is then vibrated and sieved through a sieve with a pore size of 200 μm After mixing with rubber, the concentration of rubber solution is 11.5%, and the amount of addition is 9000mL. After stirring evenly, put it into a drying cabinet with a vapor pressure of 0.35Mpa, and dry it for 120 minutes; finally, grind the dried material through a 450μm aperture sieve to obtain the mixed powder ready for use;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com