Method for separating acetic acid and water by complexation extraction and rectification

An extractive distillation and complexation technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of complex operation control, large amount of extractant, large amount of azeotrope, etc. The effect of improved volatility and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

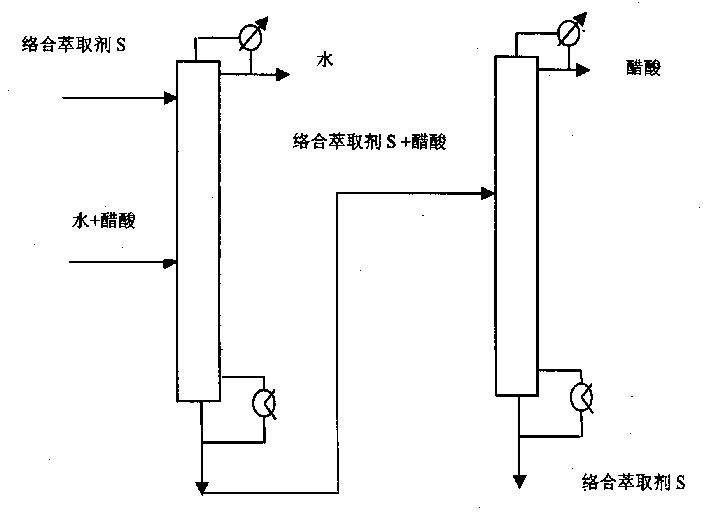

[0020] Such as figure 1 As shown, the experimental process consists of an extractive distillation column 1 and a solvent recovery column 2. The extractive distillation tower has 30 theoretical trays (the number of trays is counted from top to bottom), and the tributylamine liquid mixture (mass fraction exceeding 15%) that contains a small amount of acetic acid is selected as the complex extraction agent, from the 4th theoretical plate The plate is added, and the flow rate is 10ml / min. The mixture of acetic acid and water is added from the 15th theoretical plate, and the composition is 71.13wt% of water, 28.87wt% of acetic acid, and the flow rate is 10ml / min. The extractive distillation tower is operated under normal pressure, the reflux ratio at the top of the tower is 1, the temperature at the top of the tower is controlled at 99.5°C-101.0°C, the mass fraction of water at the top product is 99.74%, and the mass fraction of acetic acid is 0.26% through gas chromatography analy...

Embodiment 2

[0022] Same as in Example 1, the experimental process consists of an extractive distillation tower and a solvent recovery tower. The extractive distillation tower has 30 theoretical trays (the number of trays is counted from top to bottom), and the tributylamine liquid mixture (mass fraction exceeding 10%) that contains a small amount of acetic acid is selected as the complex extraction agent, from the 4th theoretical plate The plate is added, and the flow rate is 10ml / min. The mixture of acetic acid and water is added from the 15th theoretical plate, and the composition is 71.13wt% of water, 28.87wt% of acetic acid, and the flow rate is 10ml / min. The extractive distillation tower is operated under normal pressure, the top reflux ratio is 0, the top temperature is controlled at 99.5°C-101.0°C, the top product is analyzed by gas chromatography, the mass fraction of water is 99.81%, and the mass fraction of acetic acid is 0.19% %, to meet the separation requirements. The soluti...

example 3

[0023] Same as in Example 1, the experimental process consists of an extractive distillation tower and a solvent recovery tower. The extractive distillation column has 30 theoretical trays (the number of trays is counted from top to bottom), and the tripentylamine liquid mixture (mass fraction exceeding 10%) that contains a small amount of acetic acid is selected as the complex extraction agent, from the 4th theoretical plate The plate is added, and the flow rate is 10ml / min. The mixture of acetic acid and water is added from the 15th theoretical plate, and the composition is 69.97wt% of water, 30.03wt% of acetic acid, and the flow rate is 10ml / min. The extractive distillation tower is operated under normal pressure, the reflux ratio at the top of the tower is 1, and the temperature at the top of the tower is controlled at 99.5°C-101.0°C. The mass fraction of water at the top product is 99.77% and the mass fraction of acetic acid is 0.23% through gas chromatography analysis. %...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com