Rolling artificial knee joint

An artificial knee joint, rolling technology, applied in the direction of knee joint, elbow joint, joint implant, etc., can solve the problems of long-term failure of prosthesis, large amount of wear, low friction coefficient, etc., to avoid biological toxicity, Considerable economic benefits, obvious social benefits and effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

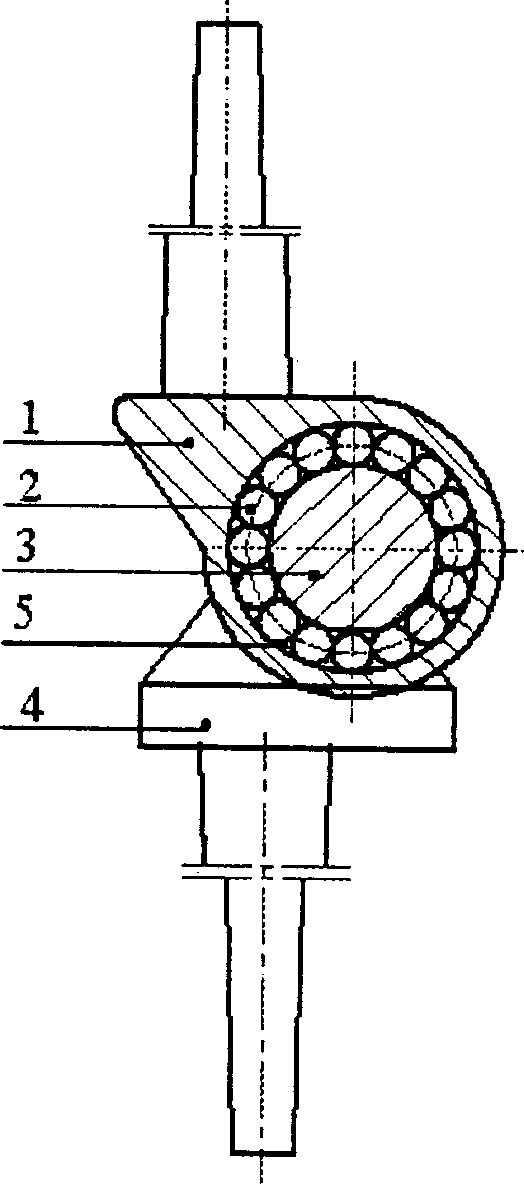

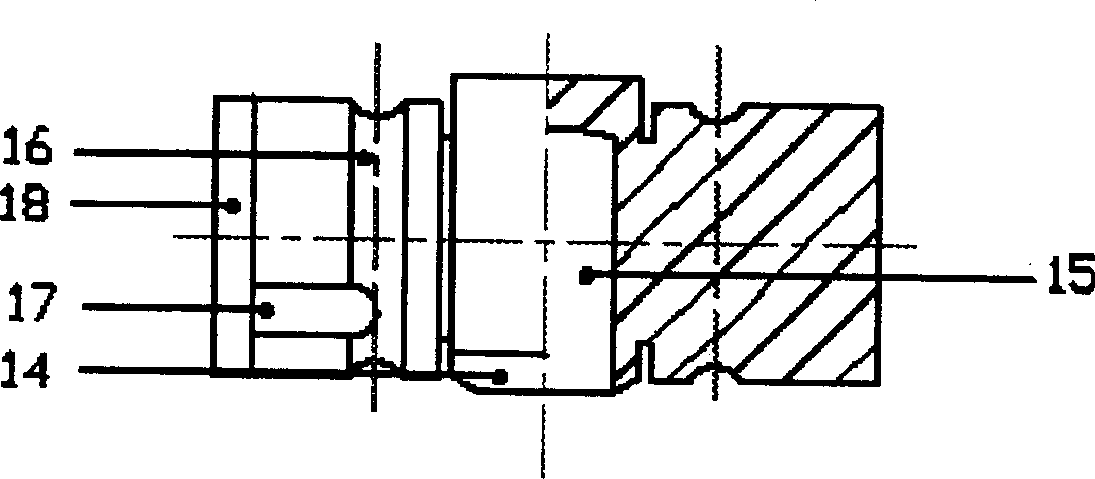

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention mainly includes: femoral component 1, rolling element 2, mandrel 3, and tibial component 4. The connection method is: femoral component 1 and mandrel 3 have two raceways 12 and 16, corresponding to raceways. Combine to form two annular spaces 5 with a circular cross-section, the rolling element 2 is arranged in the annular space 6, the cylindrical protrusion 19 of the tibial component 4 is connected to the concave hole 15 of the spindle 3, and the spindle 3 is in the femoral component In the medial and lateral condyles 11 of 1, the femoral component 1, the rolling element 2, and the mandrel 3 form a structure equivalent to two rolling bearings.

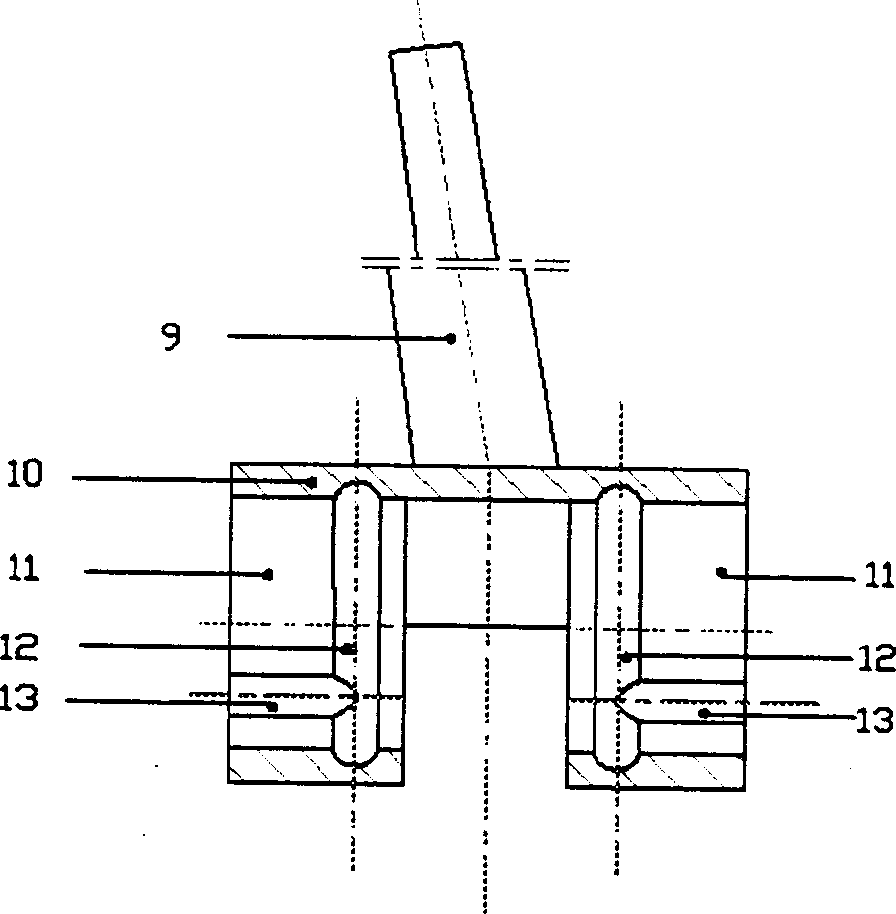

[0016] Femoral component 1 includes: intramedullary shaft 9, femoral platform 10, internal and external condyle 11, raceway 12, ball-loading gap 13, and its connection method is: except for intramedullary shaft 9, each part of femoral component 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com