Chemical applying method and its applying device

A coating device and liquid medicine technology, which is applied to the surface coating liquid device, transmission device, gear transmission device, etc., can solve the problems of non-concentrated high-pressure air flow, gap difference, and difficulty in uniform dispersion of liquid medicine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

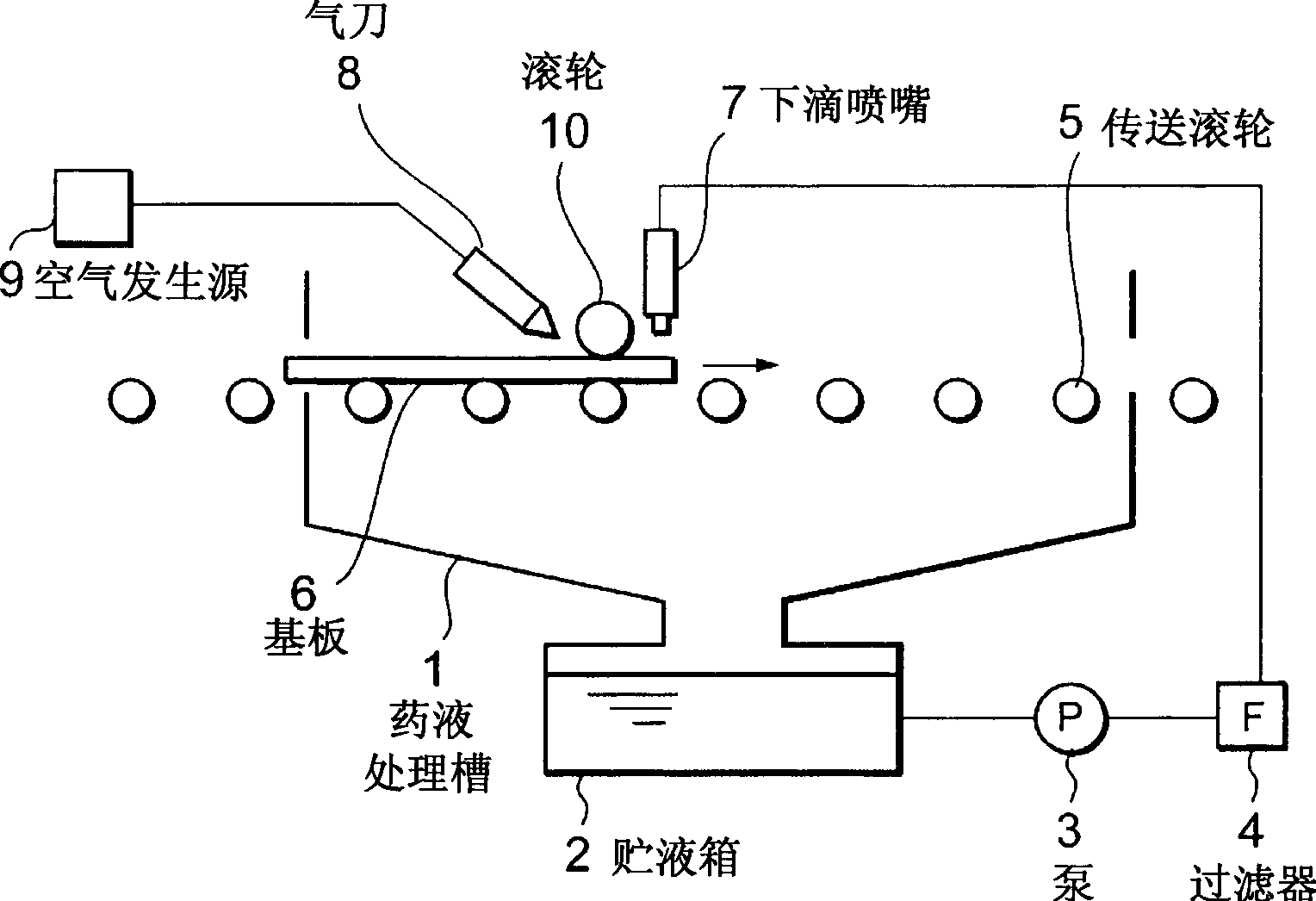

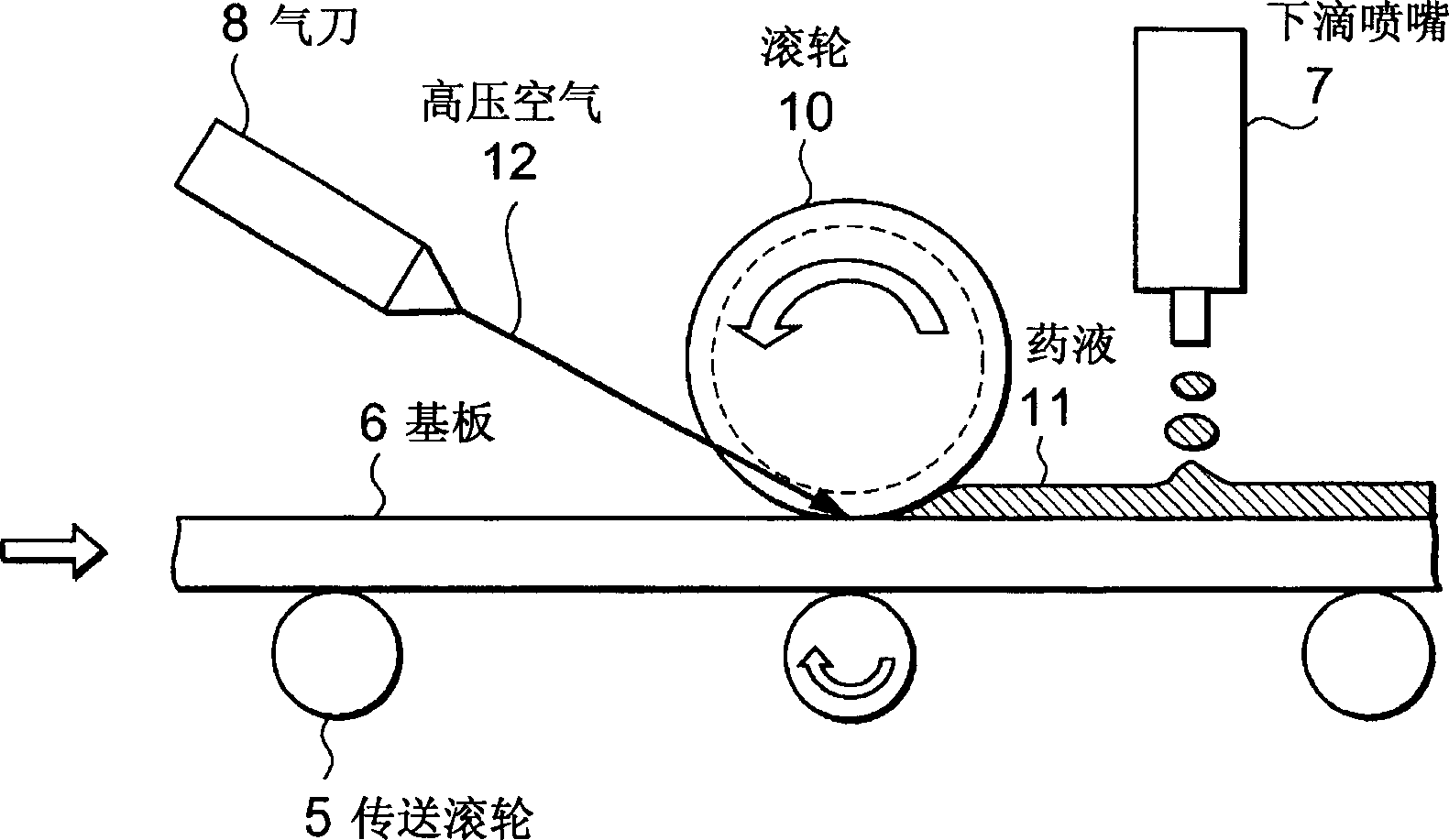

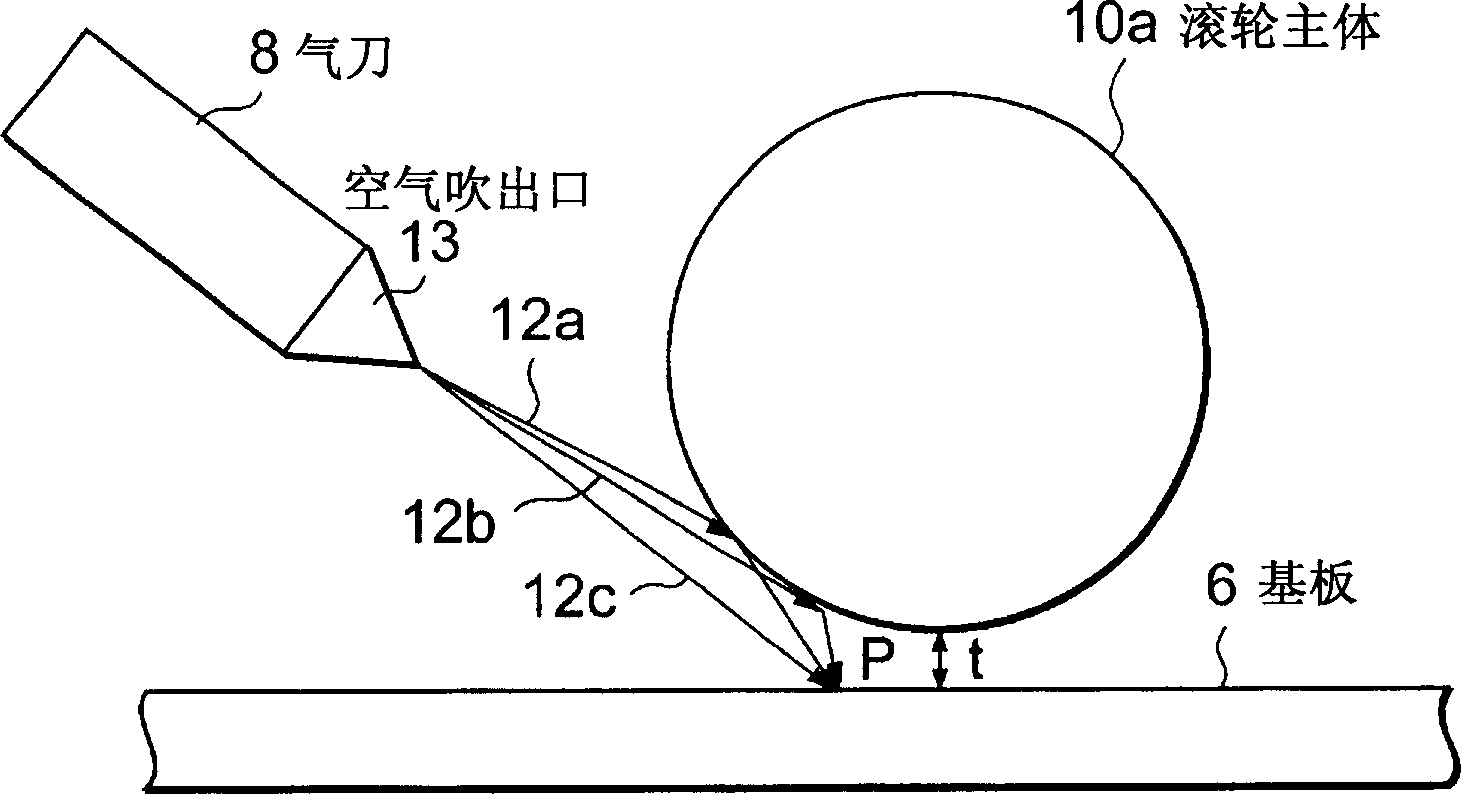

[0025] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a schematic configuration diagram of the chemical solution application device used in the present invention. In addition, the same parts as those of the conventional device are described with the same reference numerals.

[0026] Such as figure 1 As shown, the liquid medicine coating device of the present invention includes: a liquid medicine treatment tank 1, which is used to apply the liquid medicine on a large substrate 6 such as a glass substrate for liquid crystal; (exist figure 1 The middle is the left end) Carry the substrate 6 into the chemical solution processing tank 1 at a certain speed, and from the other end of the chemical solution processing tank 1 ( figure 1 The middle is the right end) The substrate is carried out at a certain speed to the delivery part outside the liquid medicine treatment tank 1; the liquid storage tank 2 of the liquid me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com