Engine perfomance monitoring method and monitor

A monitoring device and engine technology, applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve the problems of not being able to be installed on the vehicle, too many sensors, excessive detection, etc., to prevent major accidents and anti-interference ability. Strong, high-precision control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

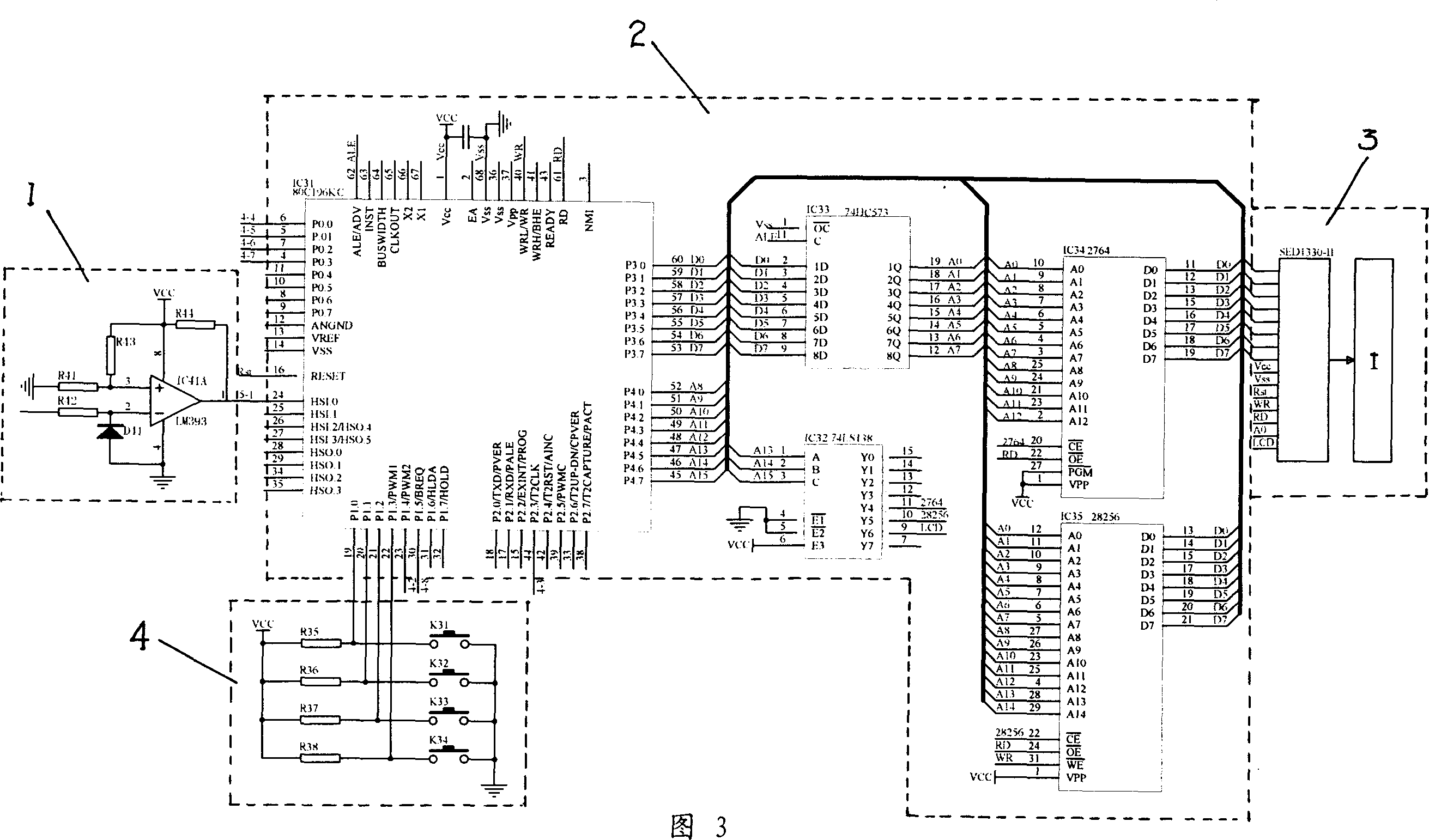

[0035] The principle of the engine performance monitoring method that the present invention proposes is:

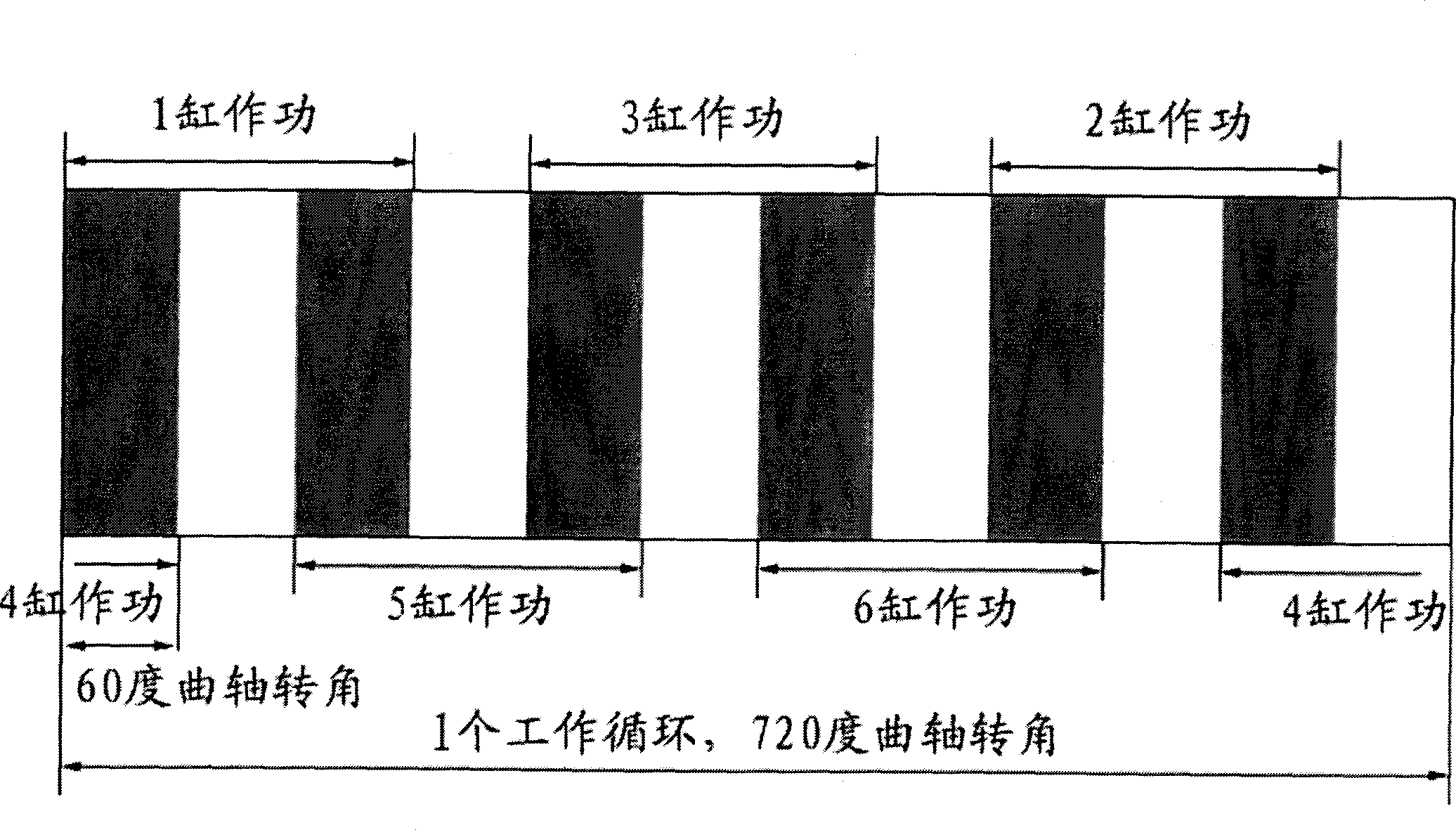

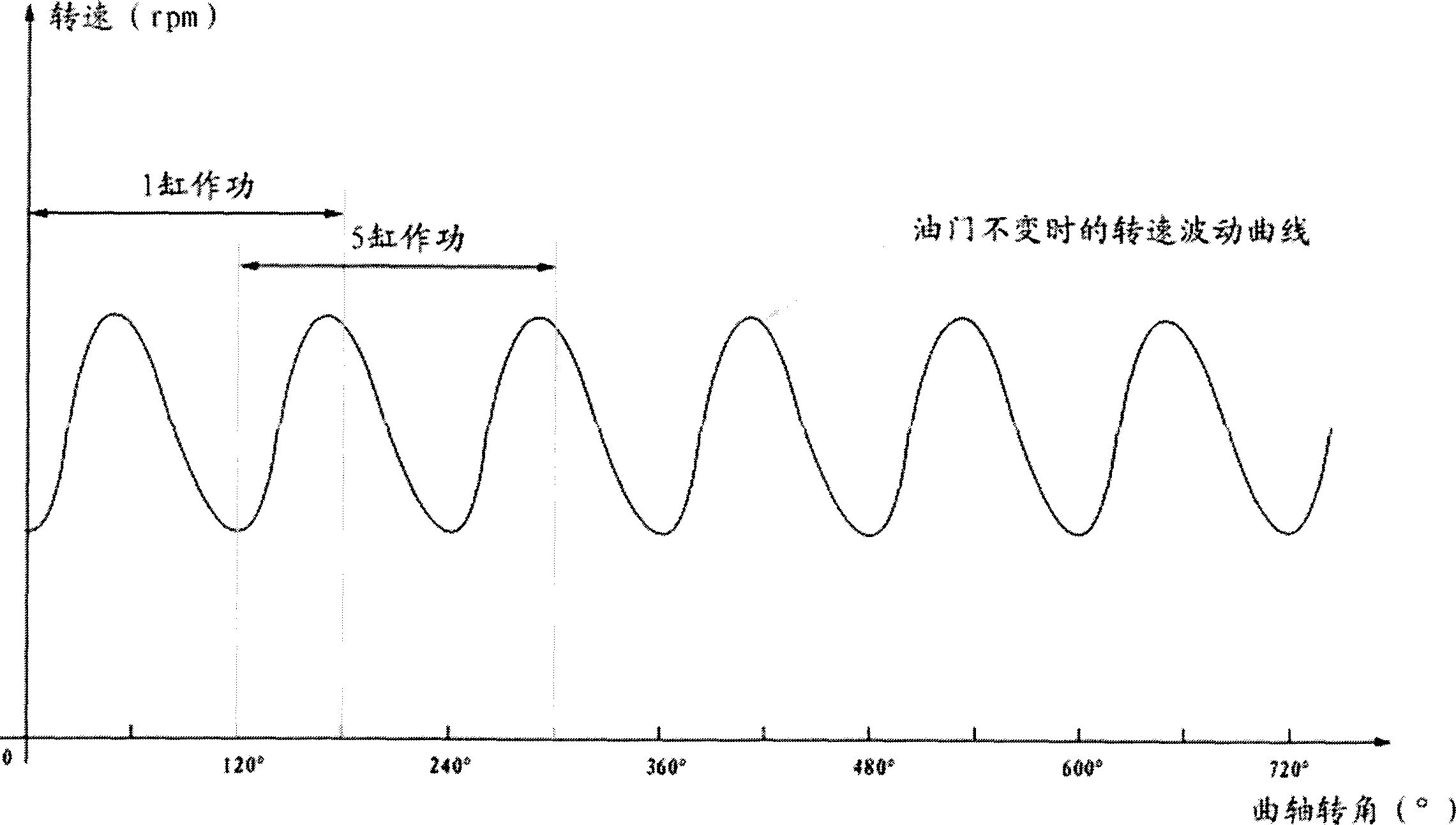

[0036] When the engine is running normally and the throttle is constant, the engine speed does not remain constant, but changes slightly. The reason is that when the engine cylinder works, the combustion gas expands to push the piston, connecting rod, and crankshaft to rotate, so that the engine speed When the cylinder does not work, due to the inertia of the flywheel, the crankshaft drives the piston to rotate, and the speed decreases. The more cylinders of the engine, the smaller the slight difference in the rotational speed between the above-mentioned engine cylinders doing work and not doing work, but due to the overlap of the power strokes, the slight change in the rotational speed when the engine throttle is constant still exists.

[0037] Take an in-line six-cylinder four-stroke internal combustion engine as an example.

[0038] 1. For a six-cylinder four-stroke e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com