Voltage sensor

A technology of voltage sensor and capacitive voltage divider, applied in the direction of voltage divider, etc., can solve the problems of poor insulation performance, complicated production process, difficult output of voltage transformer, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments of the accompanying drawings.

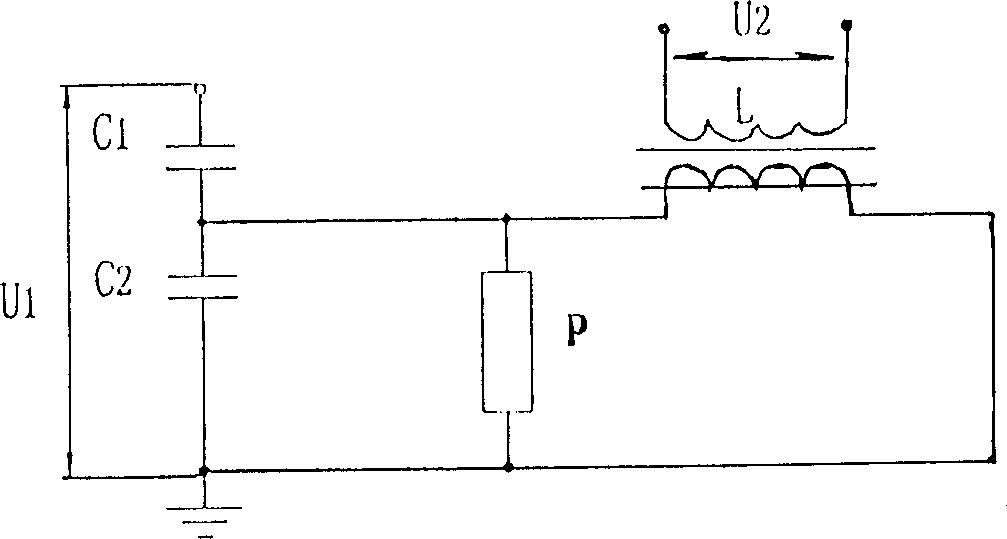

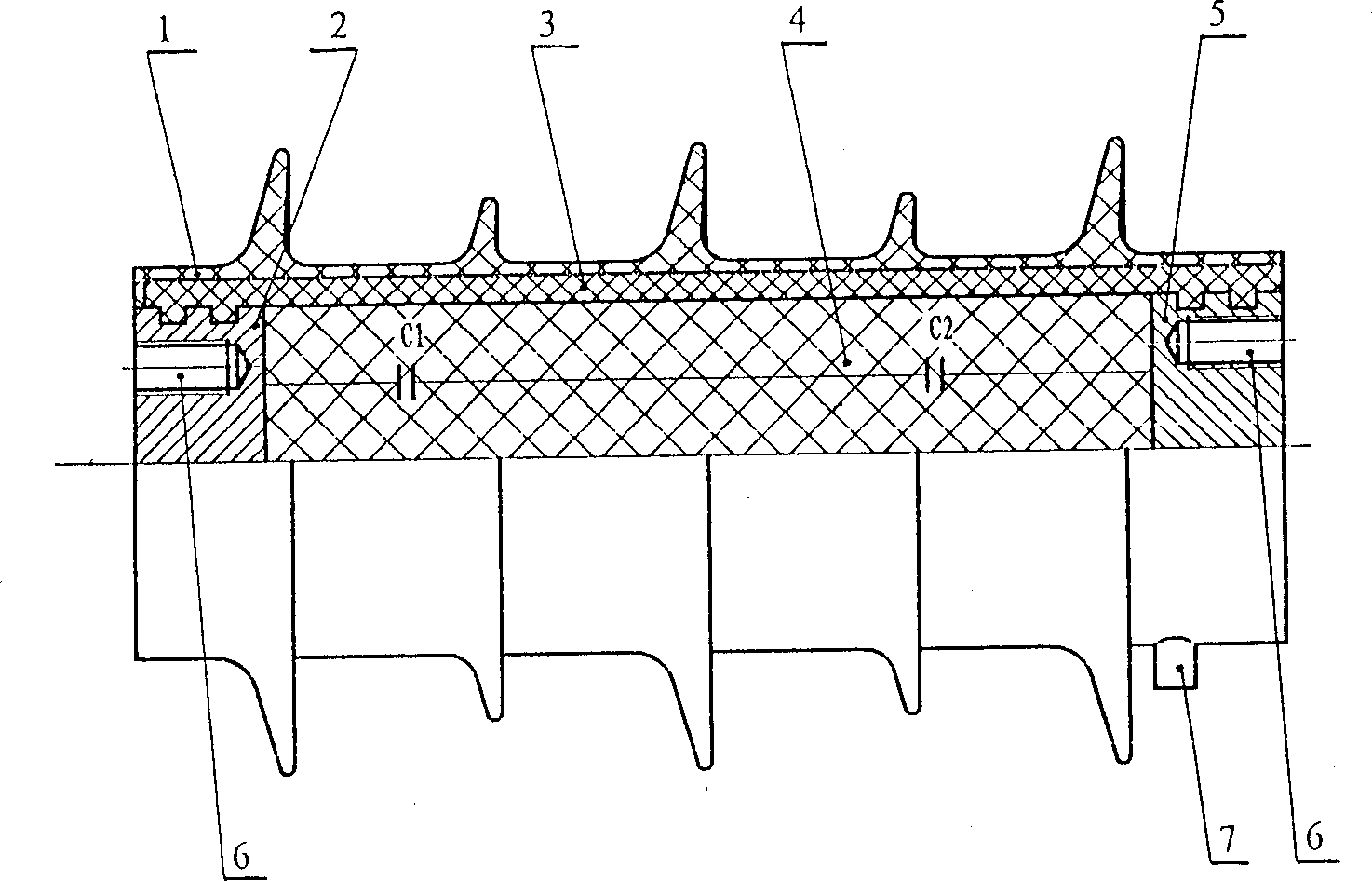

[0017] The voltage sensor consists of a capacitive divider (see Figure 1-2 ), the capacitive voltage divider has an insulating casing 1 made of silicone rubber with an umbrella skirt and an insulating cylinder 3 made of epoxy resin to form an insulating shell, the insulating cylinder is set in the insulating sleeve, and the insulating cylinder The two ends of the hole are made of rectangular threads, and the 10KV high-voltage end 2 connected to the high-voltage power grid and the fixed grounding end 5 are made of metal, which are screwed to the two ends of the insulating cylinder, and the grounding end is made into a concentric ring , so that there are holes for pouring, the high-voltage end 2 is provided with a prefabricated screw hole 6 connected to the high-voltage busbar, and the grounding end 5 is provided with a prefabricated screw hole 6 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com