Foreign matter eliminating device

A technology of removing device and foreign matter, which is used in solid separation, sorting, and separation of solids from solids by air flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

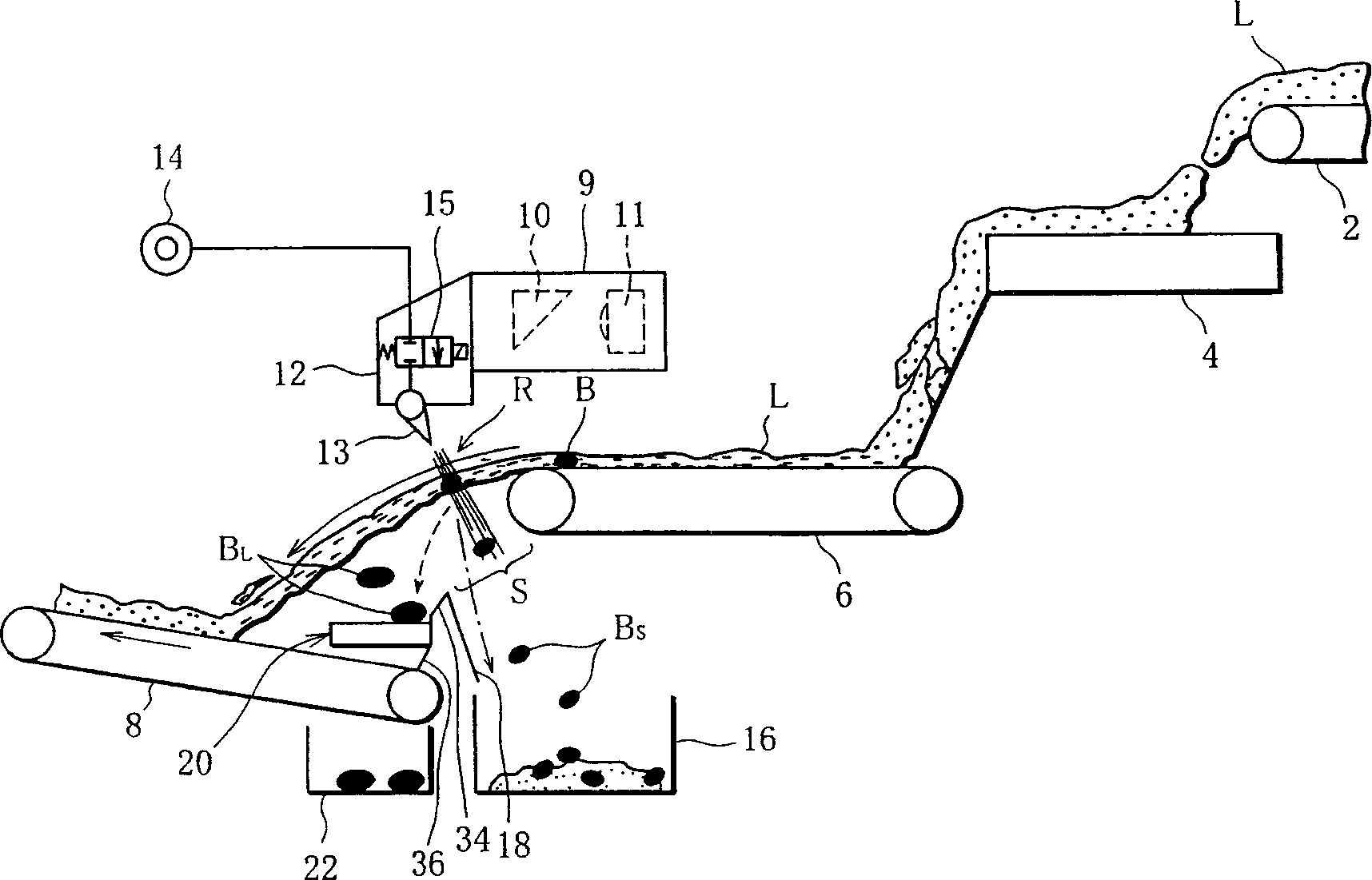

[0020] refer to figure 1 , as an example, a schematic description will be given of the structure of a foreign matter removal device applied to a raw material processing step of a cigarette raw material factory.

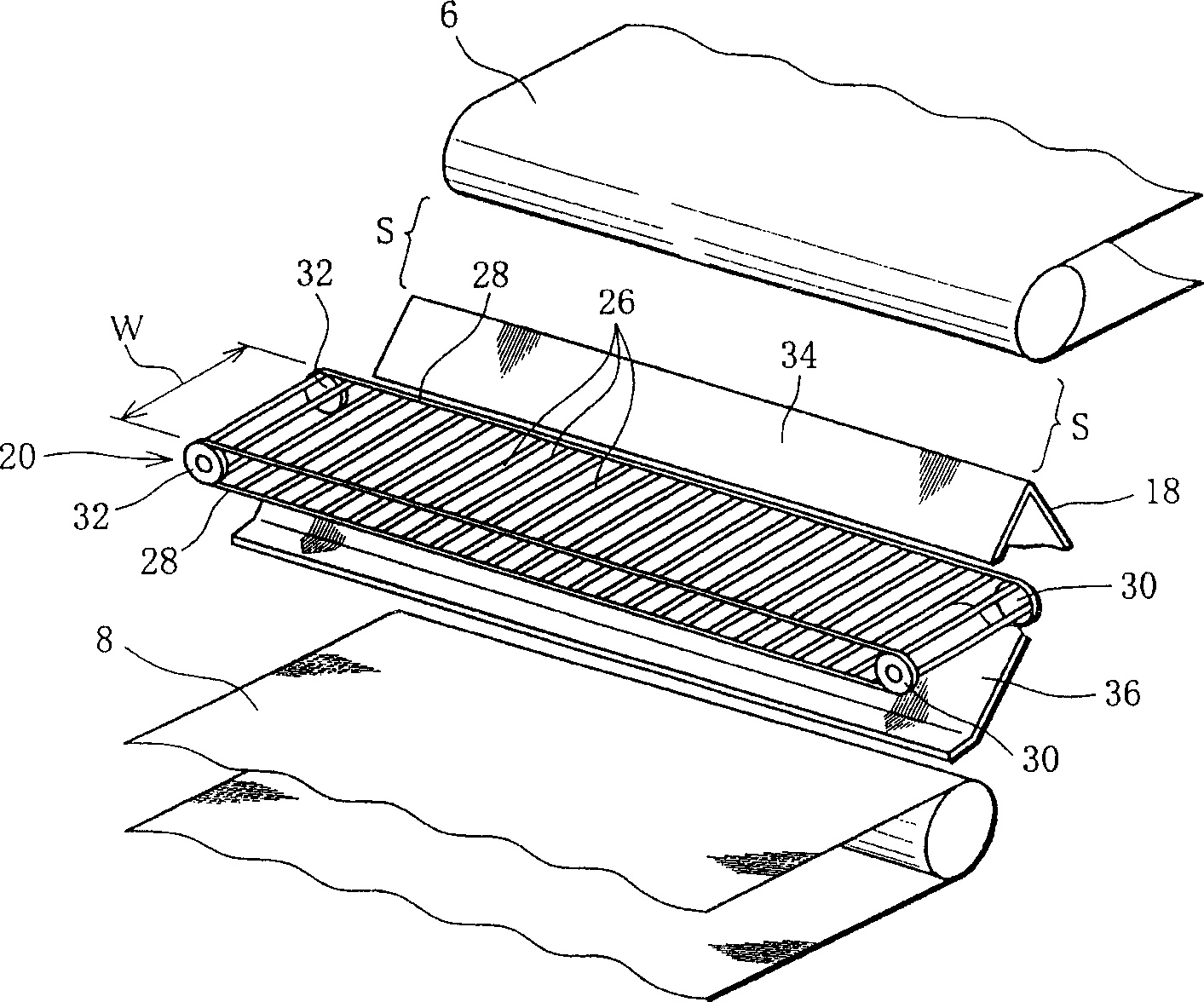

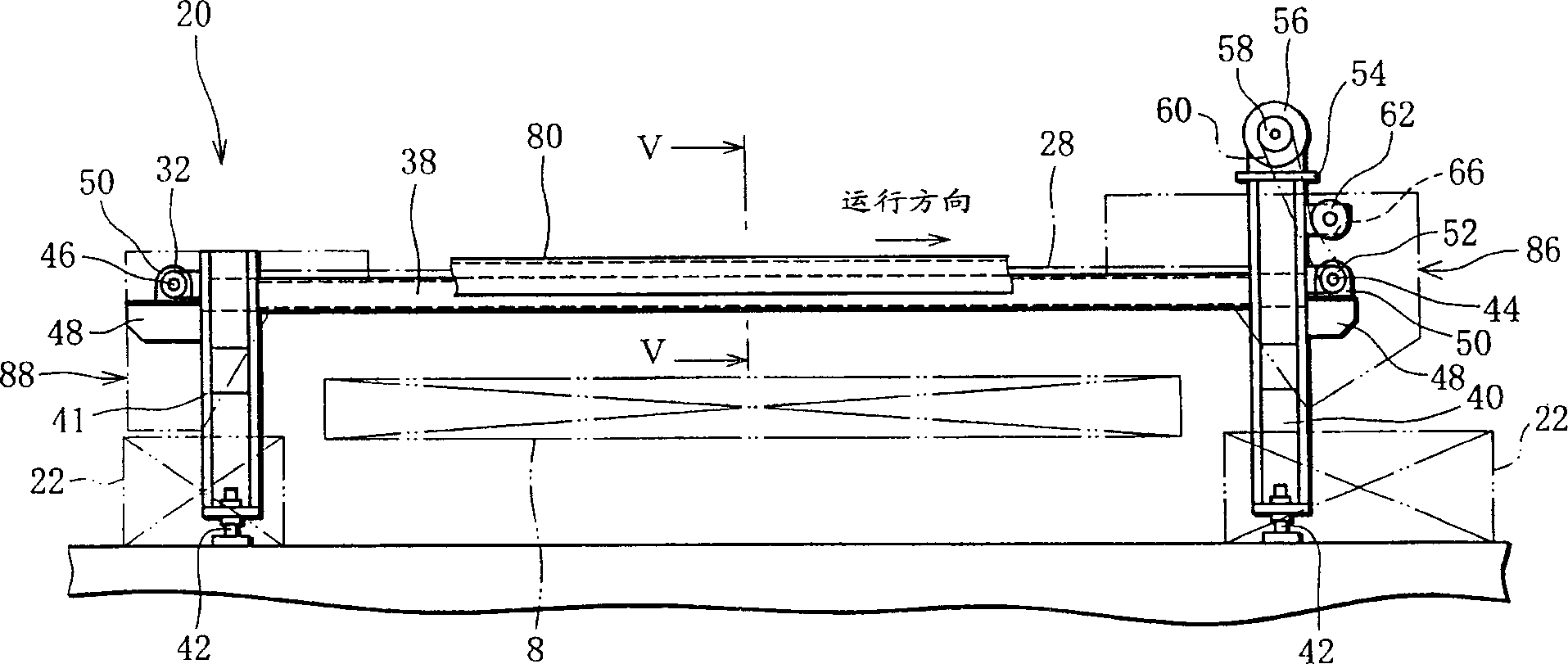

[0021] exist figure 1 In the raw material processing step shown, the raw tobacco leaf L is first continuously conveyed from the conveyance conveyor 2 to the unfolding conveyor. The distribution of the tobacco leaves L in the following unfolding conveyor belt 4 is extended to the entire width of the main conveyor belt 6, and then the tobacco leaves L are sent to the main conveyor belt 6 as they are. The downstream conveyor belt 8 is arranged below the main conveyor belt 6 and directly in front of the end thereof. The downstream conveyor belt 8 receives the tobacco leaves L continuously delivered from the terminal end of the main conveyor belt 6, and conveys them to an area where the following processing steps are performed.

[0022] Here, the upstream main conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com