Electric resistance welder

A resistance welding and electric power technology, applied in the field of resistance welding devices, can solve the problems of shortening the loop distance, high device cost, and difficulty in miniaturizing the power supply part, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

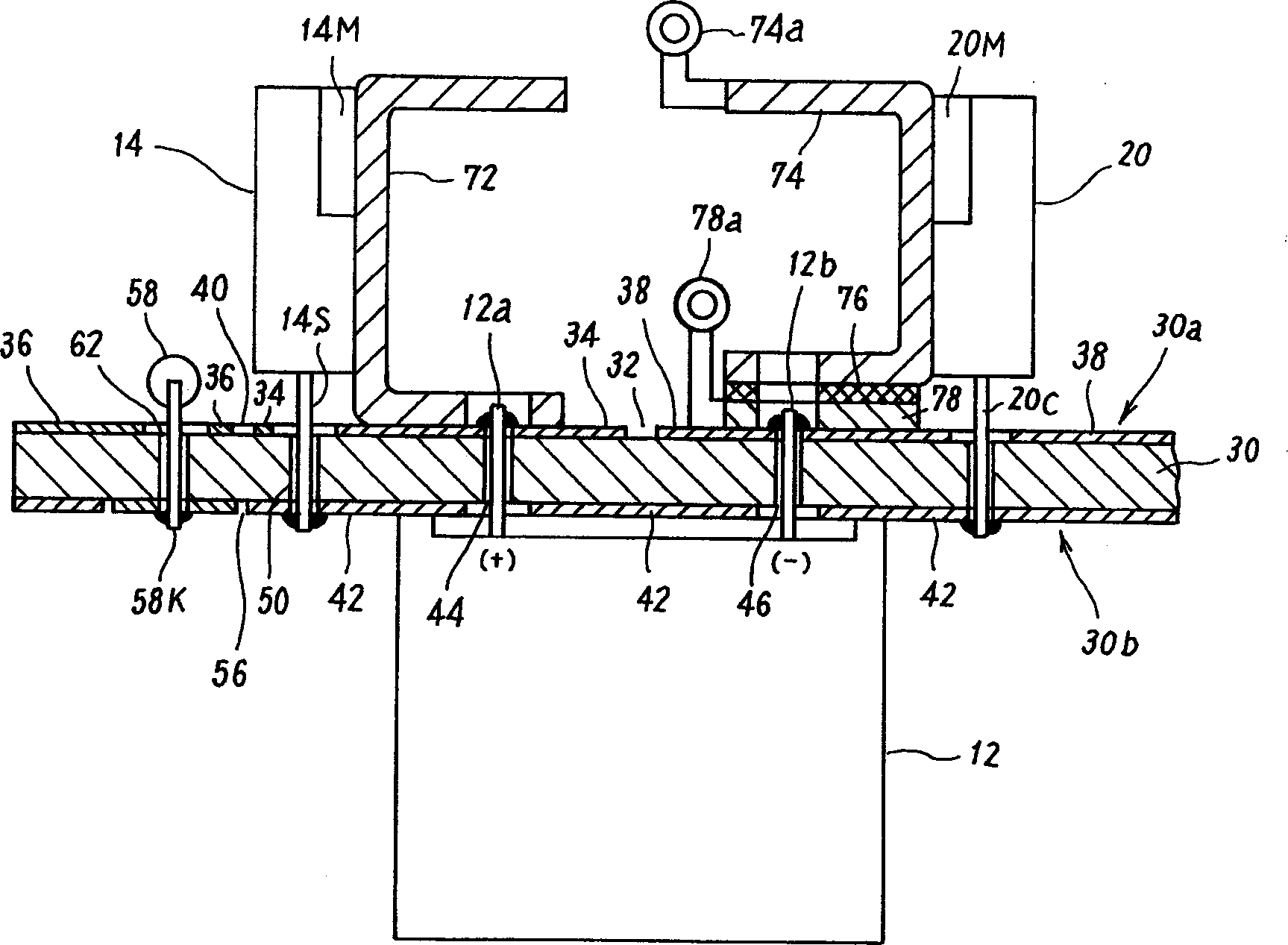

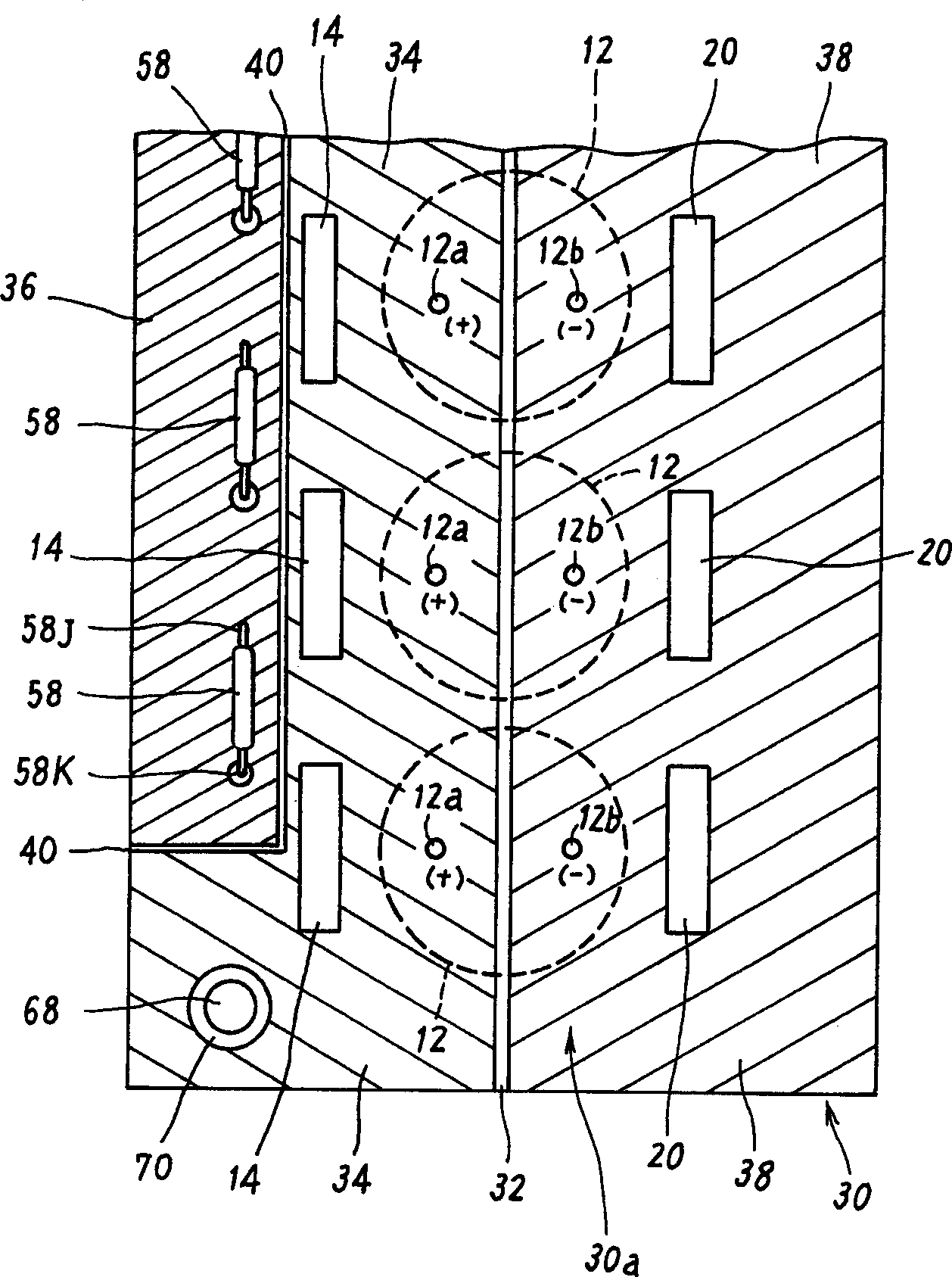

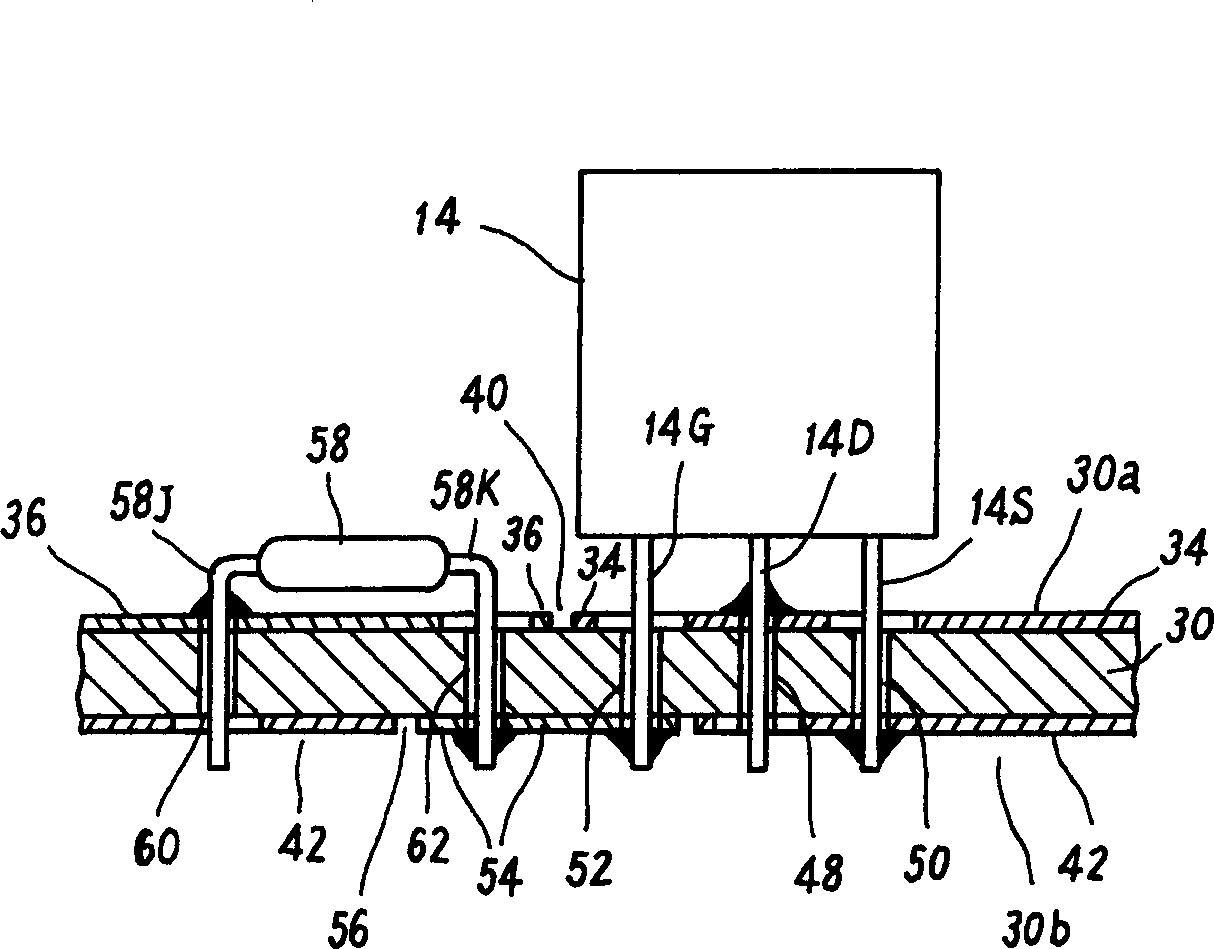

[0022] Refer below Figure 1 to Figure 5 , illustrating an ideal embodiment of the present invention.

[0023] Figure 1 to Figure 5 It shows the assembly structure of the main part of the resistance welding apparatus of one embodiment of the present invention. The resistance welding device of this embodiment also has Image 6 The circuit structure, such as figure 1 Combinations shown include Image 6 The capacitor 12, the switching transistor 14 and the freewheeling diode 20 of the circuit.

[0024] In this combination, for example, a substrate 30 made of an insulating material such as glass epoxy resin is used as a main body, and one side of the substrate 30 ( figure 1 The lower side of the) install the capacitor 12, on the opposite side ( figure 1 The upper side) of the switch transistor 14 and the freewheeling diode 20 are installed.

[0025] Conductive film conductors made of, for example, copper foil are fixedly formed on both surfaces of the substrate 30 by elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com