High-temp alkali fusing-hydrothermal crystallizing process for preparing A-type zeolite from coal gangue

A technology of hydrothermal crystallization and coal gangue, applied in A-type crystalline aluminosilicate zeolite, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problems of complex composition, waste of resources, and lower quality of zeolite products. , to achieve the effect of broad application prospects, easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

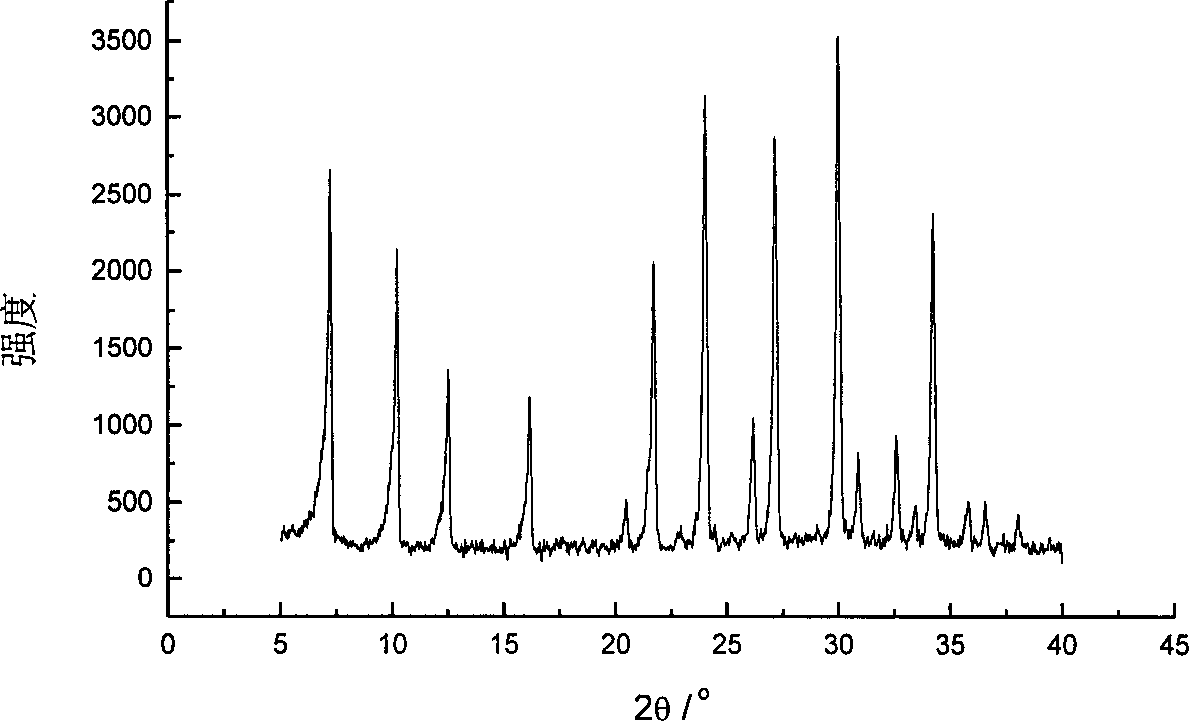

[0023] With 500 grams of coal gangue from Shanxi Sanyuan Coal Industry Co., Ltd. (containing C49.4%, SiO 2 25.8%, Al 2 o 3 13.1%, the main crystal phase is kaolinite and quartz), adding aluminum hydroxide to adjust the ratio of silicon to aluminum to SiO 2 / Al 2 o 3 is 2.5, add solid sodium hydroxide to make the alkali-silicon ratio (Na 2 O / SiO 2 ) is 1.8, and it is ground and mixed in a ball mill jar. Put the coal gangue with adjusted silicon-aluminum ratio and alkali-silicon ratio into a porcelain boat, and bake it in a muffle furnace at 850°C for 5 hours to obtain a light green frit. Add water to the frit so that the water-alkali ratio reaches 70, put it into a crystallization kettle for crystallization at 80°C for 19 hours, wash and dry to obtain a sample, and detect it as A-type zeolite, the relative crystallinity exceeds 95%. See accompanying drawing for XRD spectrum.

example 2

[0027] The experimental procedure is the same as above, but the crystallization time is shortened to 10 hours, and the obtained sample is detected as type A zeolite by XRD, and the relative crystallinity exceeds 92%.

example 3~6

[0029] Take 3 grams of coal gangue from Shanxi Sanyuan Coal Industry Co., Ltd., grind and pulverize it in a mortar, add aluminum hydroxide to make the ratio of silicon aluminum to SiO 2 / Al 2 o 3 is 2.5, add sodium hydroxide solution to make the alkali-silicon ratio (Na 2 O / SiO 2 ) is 1.8, and it is ground and dried under an infrared lamp. Put the porcelain boat into the tube furnace and bake at 120°C for half an hour to remove water, and then bake at 850°C for 3 hours in an air atmosphere. Add water to the obtained frit until the water-alkali ratio H 2 O / Na 2 O is 60, aged at room temperature for 24 hours, and crystallized at 55°C for 12, 24, 48, and 72 hours respectively. The obtained samples are all A-type zeolites after inspection, and the relative crystallinity is 36%, 87%, 91%, respectively. 100%, the impurity phase is amorphous silicon aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com