No-delay zero-crossing trigger circuit with thuristor throw-in and throw-off capacitor

A thyristor switching, capacitor technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation and other directions, can solve the problems of reduced power consumption, poor triggering characteristics of thyristors, and poor triggering characteristics of trigger circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

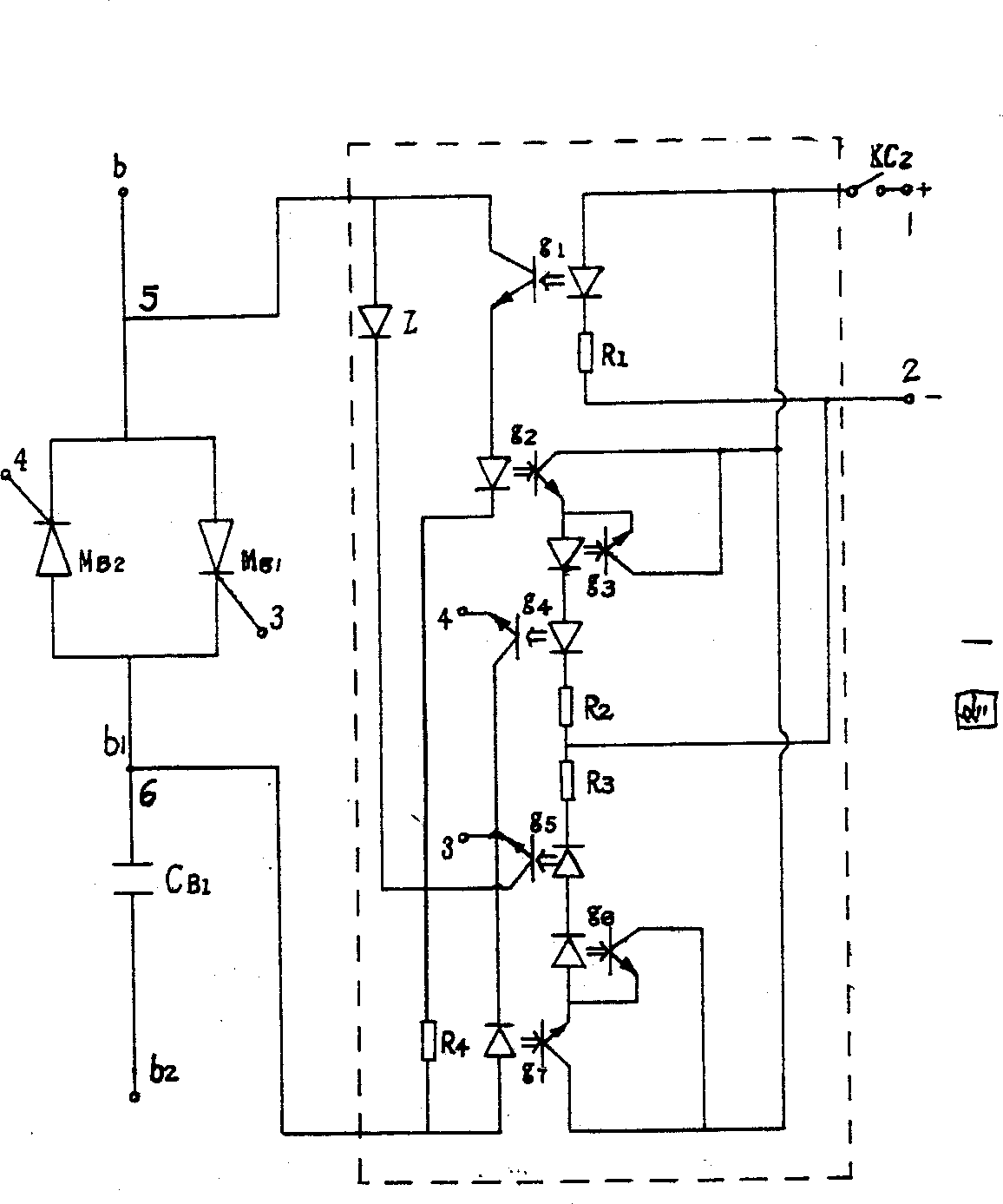

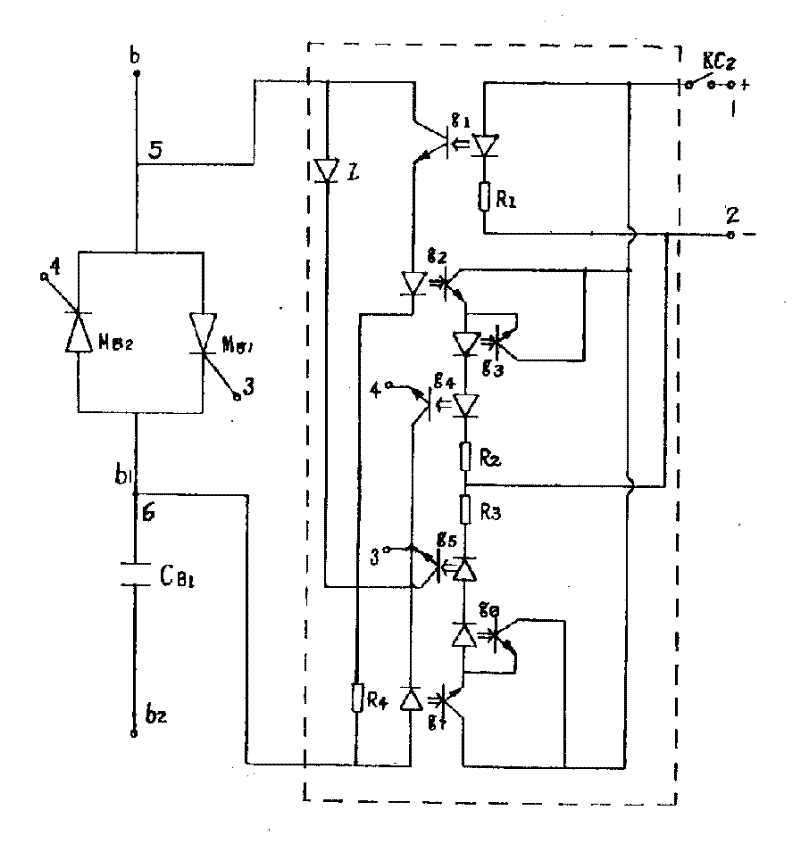

[0007] Such as figure 1 As shown in the dotted line box, the thyristor switched capacitor zero-crossing trigger circuit without delay is composed of the main control optocoupler g1, the positive and negative half-cycle conduction optocouplers g2 and g7, two holding optocouplers g3 and g6, and the negative and positive half-cycle trigger light Couplers g4 and g5 and current limiting resistors R1~R4, the input terminal of the main control optocoupler g1 and the current limiting resistor R1 are connected in series between the input terminals 1 and 2 of the DC power supply, and the output of the main control optocoupler g1 terminal, positive half-cycle conduction optocoupler g2 input terminal and current limiting resistor R4 are connected in series between the AC power input terminals 5 and 6 of the thyristor switching capacitor non-delay zero-crossing trigger circuit, and between the DC power input terminals 1 and 2 The positive half-cycle conduction optocoupler g2 output end, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com