Reflection-type diffraction grating

A diffraction grating, reflective technology, applied in the directions of diffraction grating, optics, optical components, etc., can solve the problems of reduced light intensity, complex optical system, insertion loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] The fine roughness of the diffraction grating of the present invention was produced in the following manner.

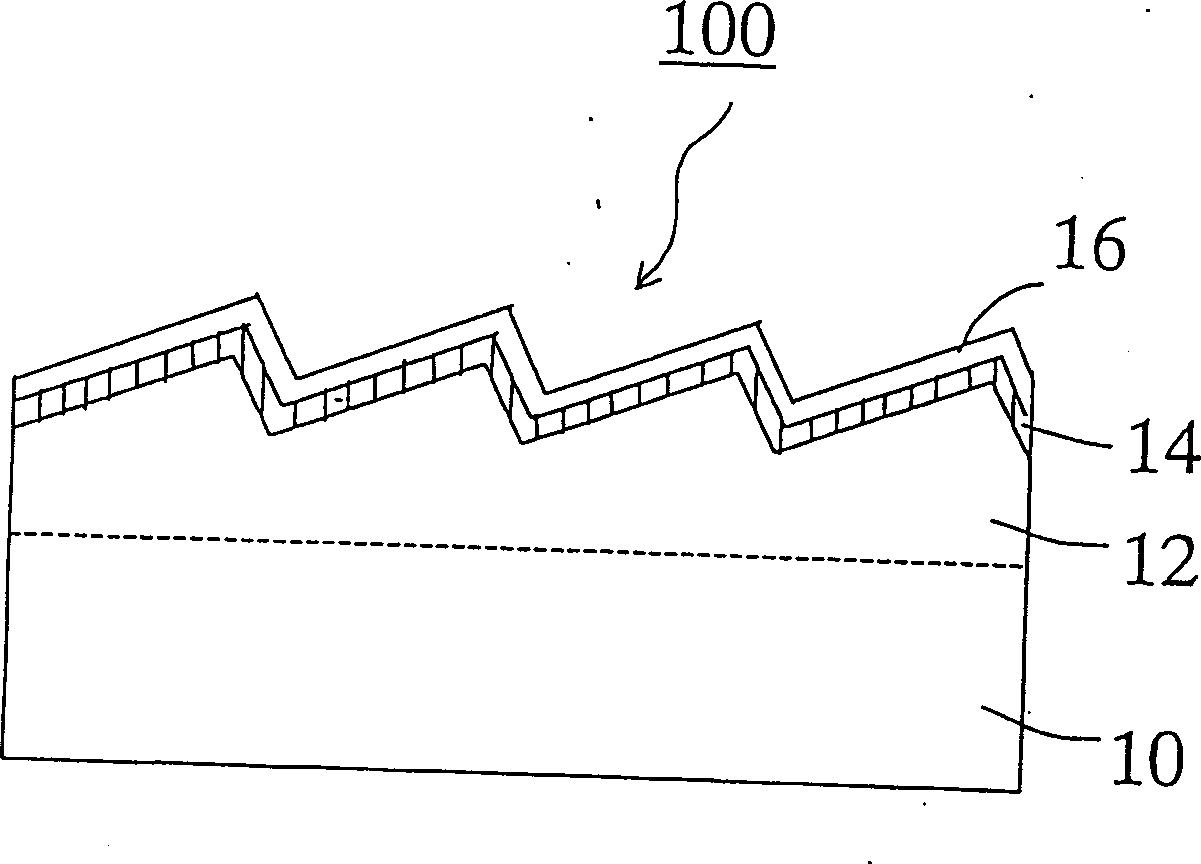

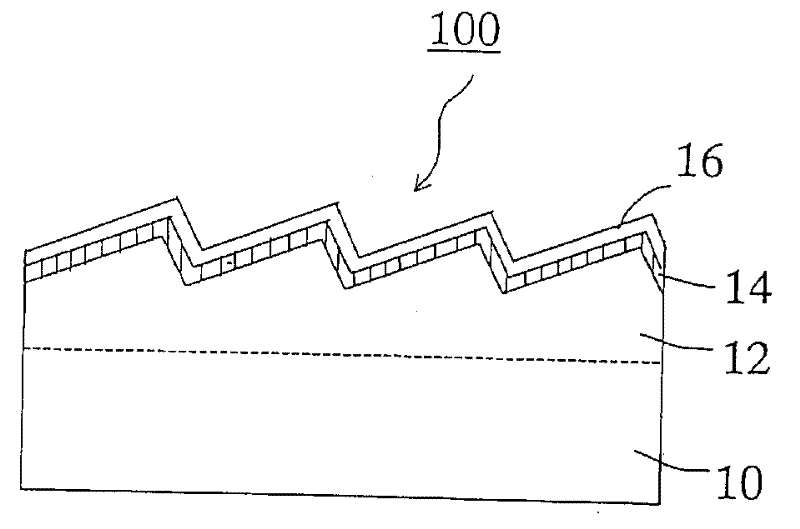

[0025] First, a soluble solution containing the liquid hydrolyzate of methyltriethoxysilane as the main component was added to the figure 1 The glass substrate 10 shown. This soluble solution added substrate 10 was molded while using a brass replica, which was subjected to a mold release process, and which is commercially available, as a stamping film. Then, mold release processing and baking are performed, whereby a fine rough structure 12 is obtained to be used as a diffraction grating. The depth of each rough groove is about 1 μm. Aluminum was vacuum-deposited on the fine roughness to form a metal film 14 with a thickness of 100 nm. Relative to unpolarized light, the reflectivity of the aluminum film is not less than 90%. Silicon dioxide (SiO 2 ) and titanium dioxide (TiO 2 ) was vacuum-deposited on the aluminum film to form an insulating film 16 consi...

example 2

[0029] aluminum and magnesium fluoride (MgF 2) were deposited on a commercially available holographic replica diffraction grating (900 / mm, provided with a reflective aluminum film formed thereon), thereby forming two thin films with thicknesses of 100 nm and 250 nm, respectively. That is, there are two kinds of metal films in this example (an aluminum film that was originally placed on the hologram replica diffraction grating and an aluminum film that was deposited on the hologram replica diffraction grating). The diffraction efficiency of the thus obtained diffraction grating with respect to a wavelength of 1550 nm was measured in the same manner as in Example 1. As a result, with respect to TE polarized light, the diffraction efficiency of the diffraction grating with a single-layer aluminum film is 32.8%, while with respect to TM polarized light, it is 82.5%, but with respect to TE polarized light, the diffraction efficiency with the aluminum layer The diffraction efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com