Elevator safety device

A safety device, elevator technology, used in transportation and packaging, friction linings, elevators, etc., can solve problems such as no longer application, whisker and platelet toxicity, and achieve high fracture strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The friction body consists of a matrix comprising 95% by weight of silicon carbide and carbon and a fiber reinforcement consisting of a laminate of carbon fiber fabrics with fiber orientations of 0° and 90°. The carbon fiber is composed of HTA fiber No. 3000 produced by Akzo and Wuppertal.

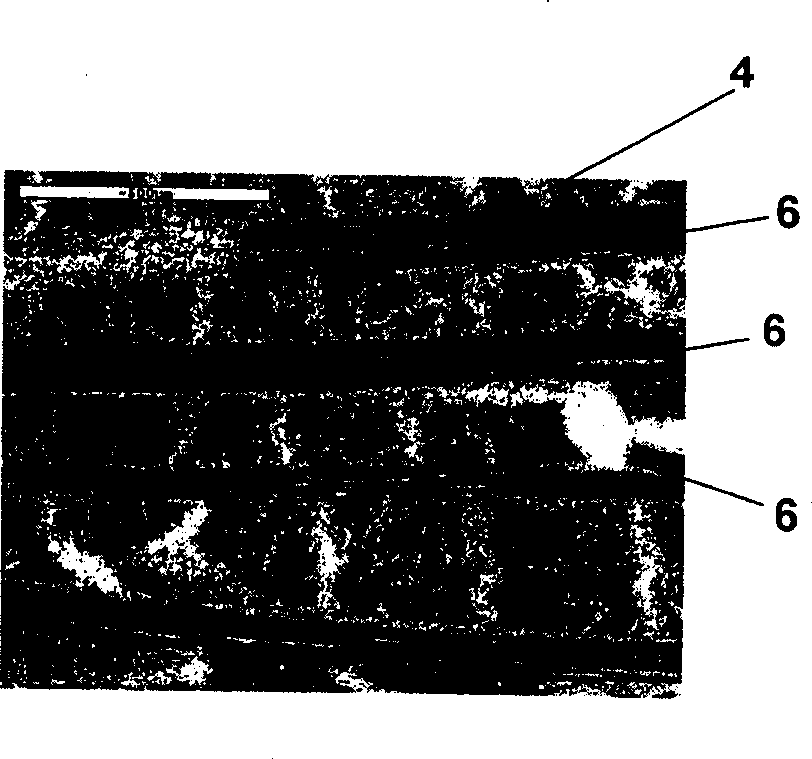

[0039] Such a friction element 1 is shown in FIG. 1 . The dimensions of the friction member are 120 mm in length, 40 mm in width and 8 mm in thickness. The two fixing holes 3 are located on the center line 2 , and the axes of the holes are perpendicular to the friction surface 4 . The axes of the two holes are each 25 mm from the narrow side of the friction element 1 . The fastening holes have a stepped profile so that fastening screws or rivets can be embedded in a wide diameter section so that they do not protrude beyond the friction surface 4 .

[0040] The manufacturing process of the friction member shown in Figure 1 includes the following steps:

[0041] First, carbon fibe...

Embodiment 2

[0053] The friction part consists of a matrix consisting mainly of silicon carbide and carbon and a fiber reinforcement (HTA fiber from Akzo, Wuppertal company No. 3000) consisting of a laminate of fiber fabrics with fiber orientations of 0° and 90° °. In order to improve the wear resistance and the coefficient of friction, the ceramic content will be greatly increased in the section close to the friction surface compared to the core section. In order to avoid deformation, the friction lining has a symmetrical structure based on the center plane of the friction thickness.

[0054] Same as Embodiment 1, the manufacturing process of the friction lining is also divided into three steps:

[0055] First, a carbon fiber reinforced plastic raw material with a fiber volume content of about 60% is prepared by resin injection molding; before impregnating the resin, inert conditions at different temperatures of 600°C, 750°C, 900°C and 1100°C Next, each carbon fiber fabric layer was cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com