Electronic cyclotron resonance dusting device for treatment of glass chip or chip

A technology for processing objects and ash chambers, which is applied in the photoengraving process of circuits, electrical components, and pattern surfaces, etc., and can solve the problems of small plasma area and difficult to large substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will now be described in detail with reference to the accompanying drawings.

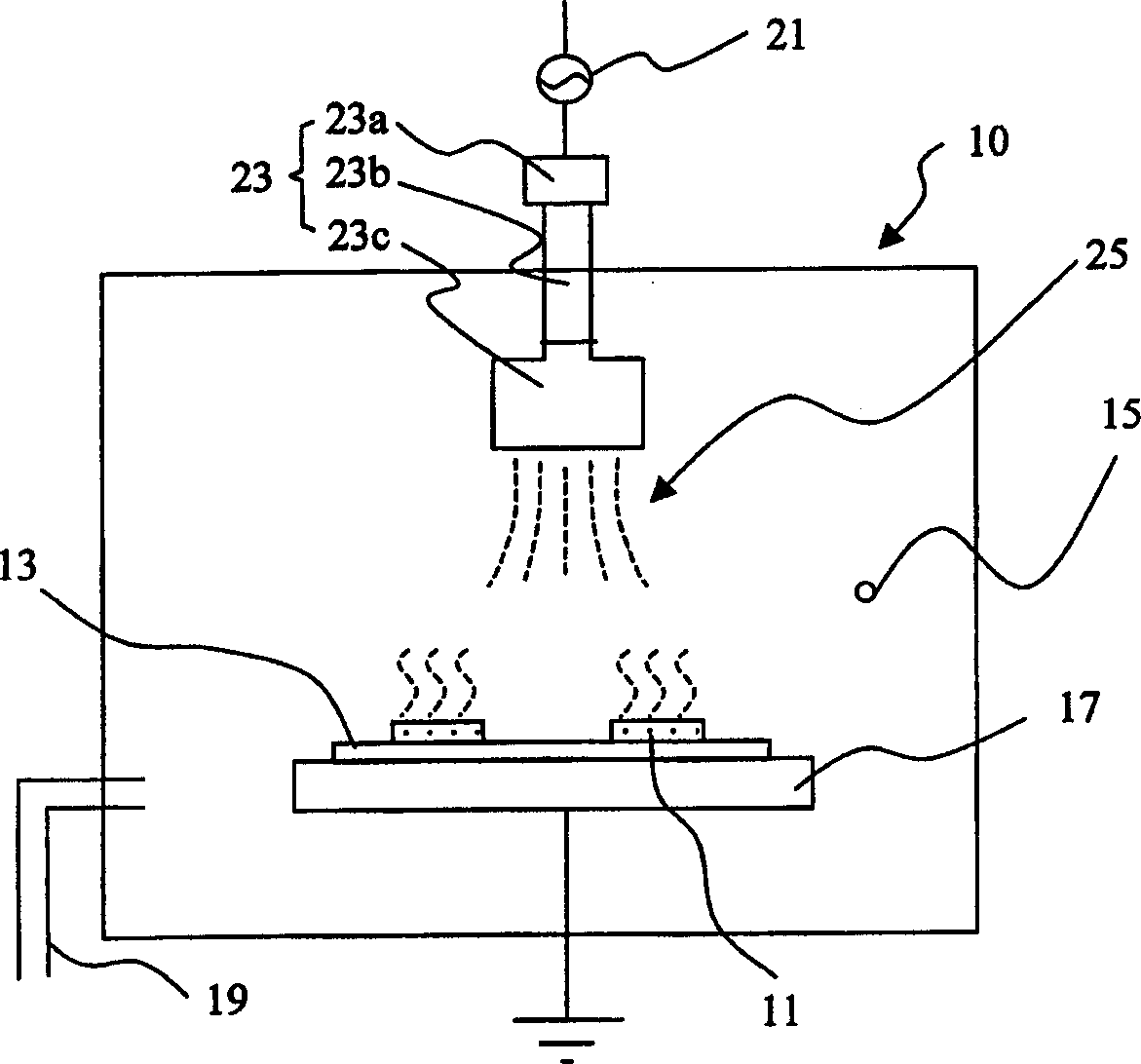

[0021] In the following description, the production of wafers in semiconductor devices is considered to be the same thing as the production of glass substrates in liquid crystal displays, so that the ECR ash removal apparatus for processing wafers will not be described.

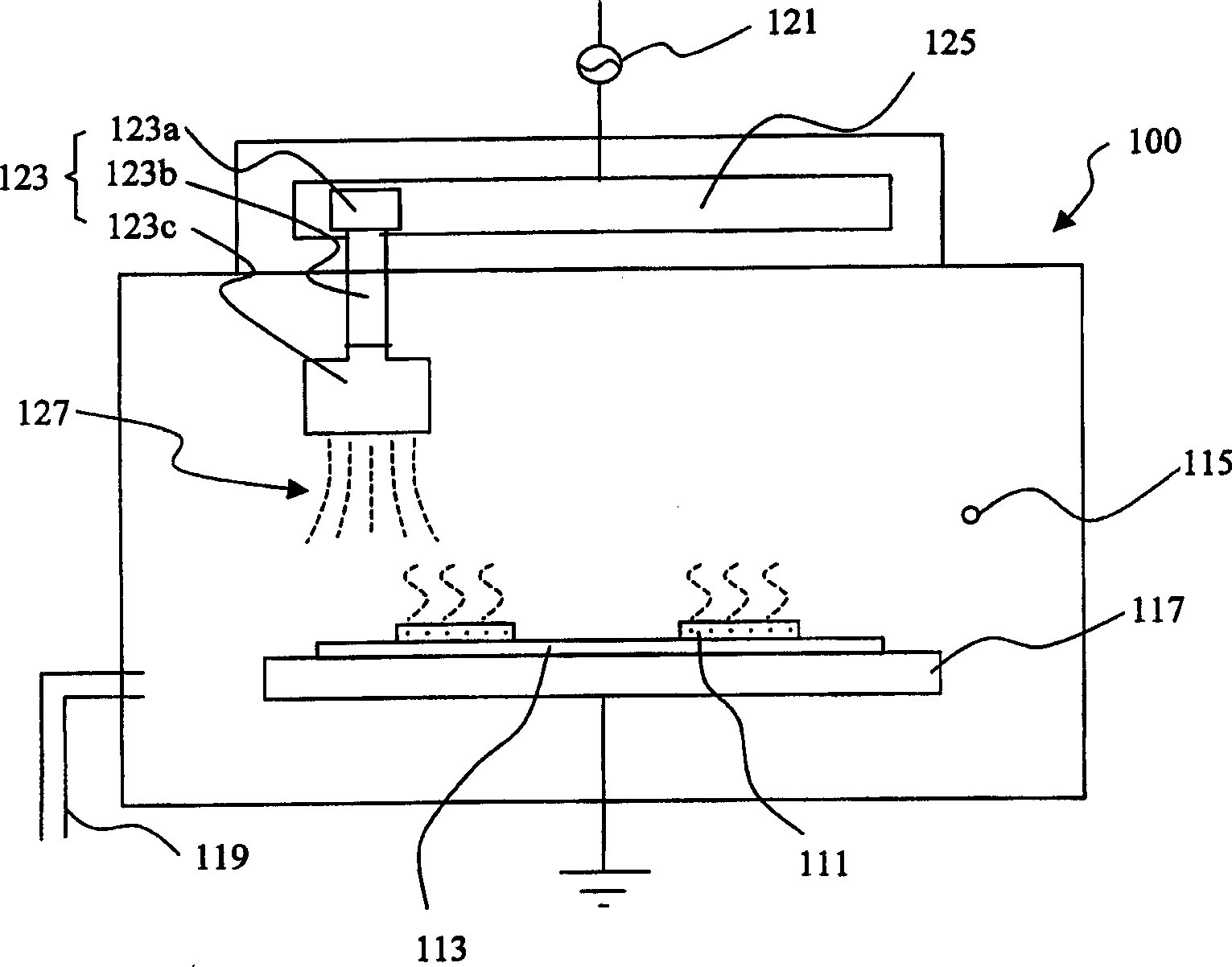

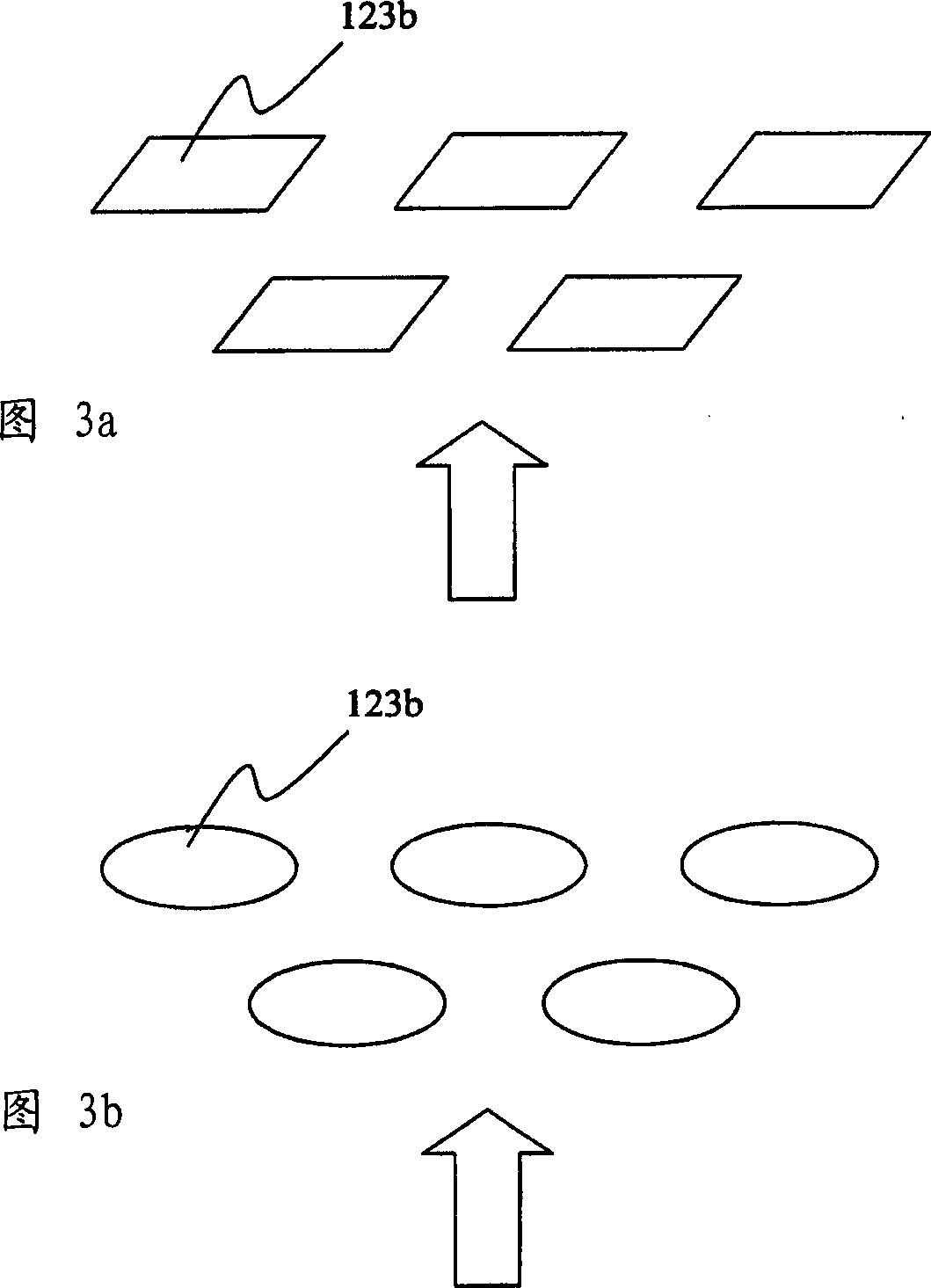

[0022] figure 2 The ECR ash removal device for liquid crystal display glass substrate according to the present invention is schematically shown. Such as figure 2 As shown, the ECR ash removal device of the present invention includes: ash removal chamber 100, an insertion port (not shown) of a glass substrate, an exhaust port 119 of ash removal gas and an air supply part 115 are provided on one side thereof; Electrode 117, in the deashing chamber 100, glass substrate 113 is installed on the lower electrode 117, wherein photoresist material 111 is applied on the glass substrate; RF power supply (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com