Method of processing semiconductor wafers to build in back surfact demage

A semiconductor and rear surface technology, applied in semiconductor/solid-state device manufacturing, machine tools suitable for grinding workpiece planes, grinding devices, etc., can solve problems affecting wafer flatness and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

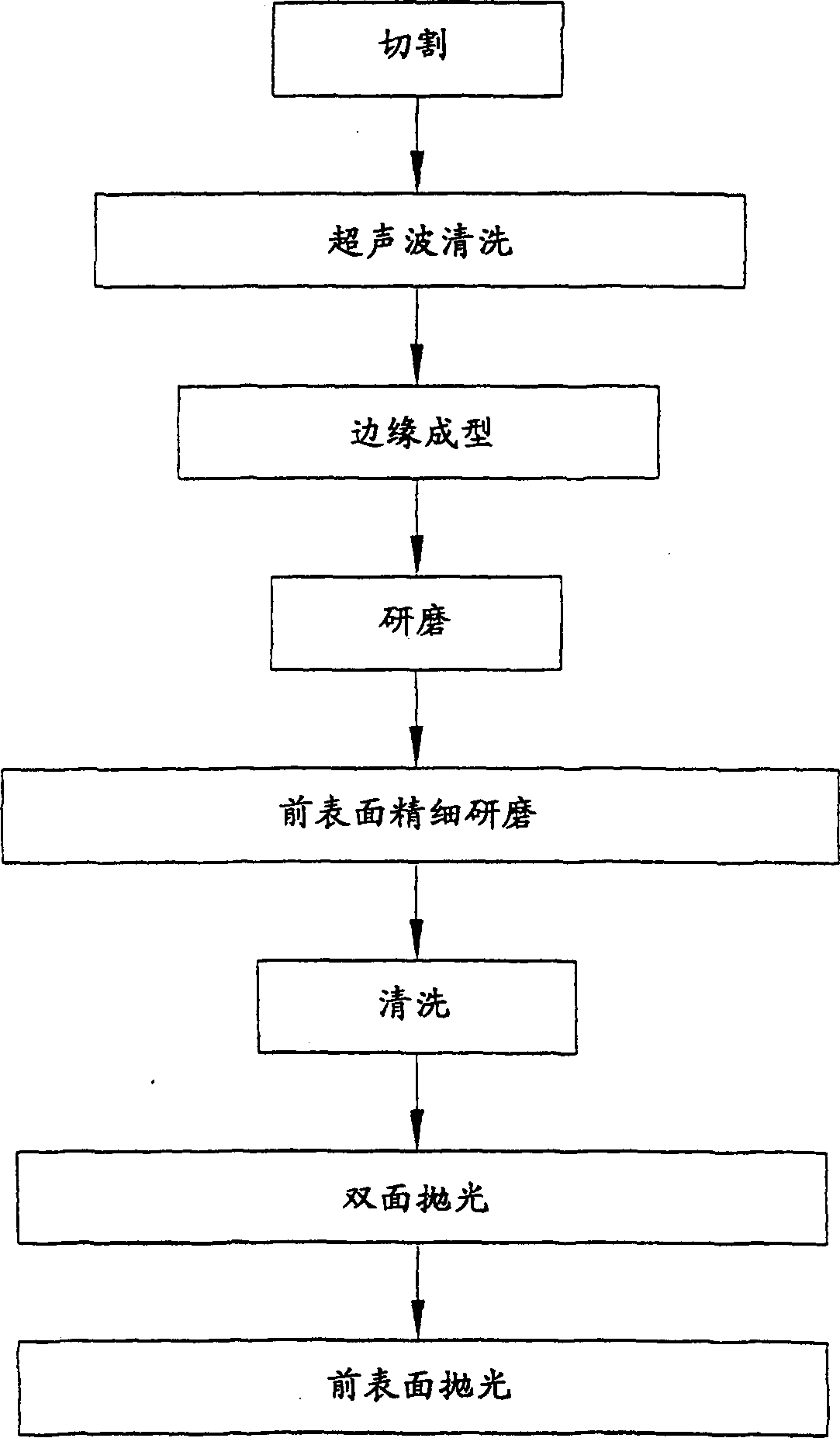

[0027] according to figure 1 Fifteen silicon semiconductor wafers having a diameter of 200 mm were processed as shown and as described in the first embodiment. The grinding operation was performed using a 15 μm particle grinding slurry, removing approximately 80 microns (40 microns on each of the front and rear surfaces) of material from each wafer. A fine grinding operation was then performed on the front surface of each wafer to remove a thickness of 15-17 microns from the wafer. Each wafer was then subjected to a DSP operation in which approximately 5-6 microns were removed from the wafer, with approximately equal amounts removed from the front and rear surfaces. After the DSP operation, the OISF count on the rear surface of one wafer was measured to be 20000 / cm2.

no. 2 example

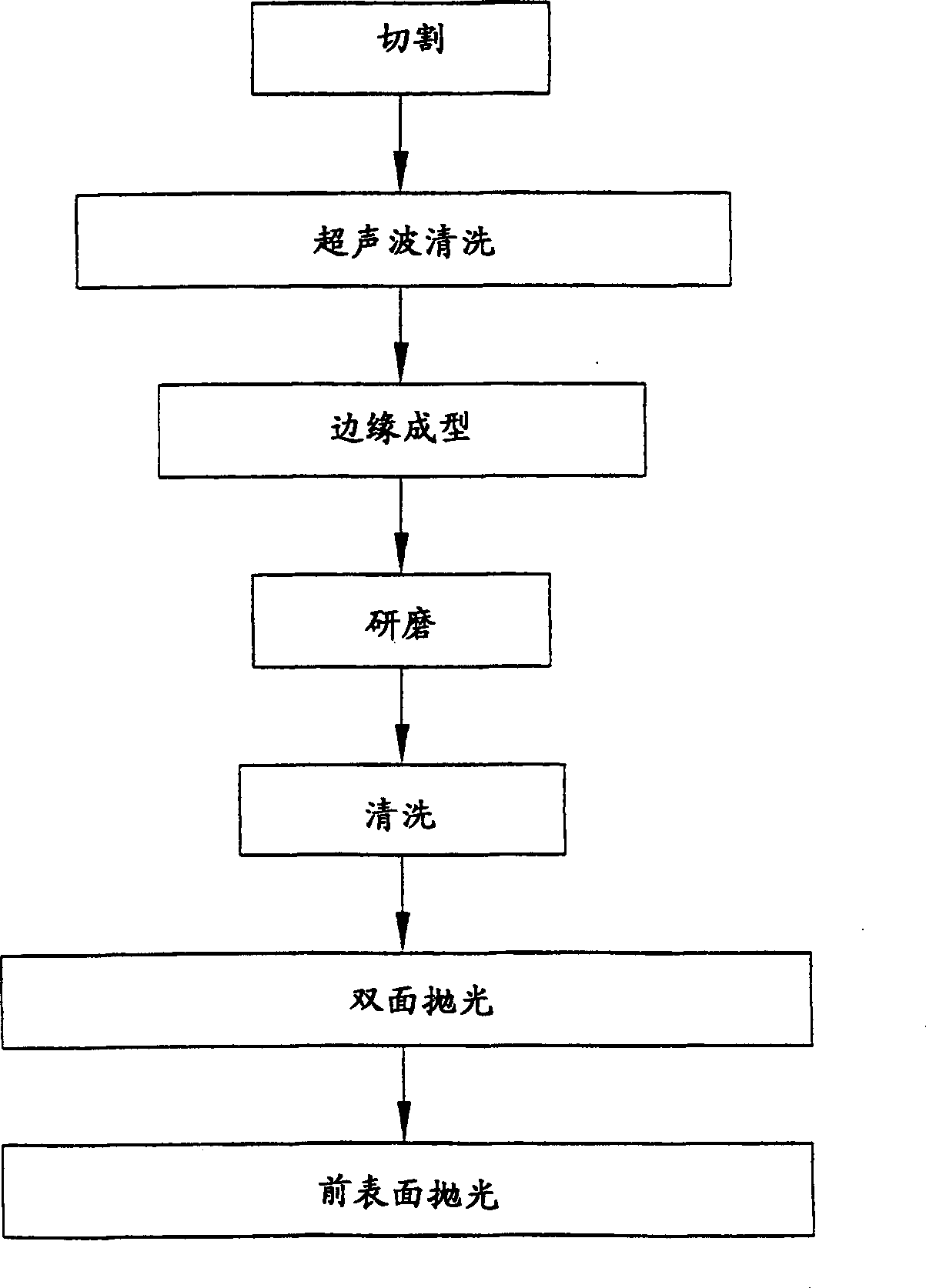

[0029] exist figure 2 In the second embodiment of the invention shown, the fine grinding step is omitted. In this second embodiment, cutting, ultrasonic cleaning, edge shaping and grinding are performed as described in the first embodiment. Only the abrasive used in the grinding equipment is preferably between about 5-10 microns. Smaller dimensions are preferred because there is less damage to the surface, which reduces the amount of wafer material that must be removed during the DSP process. The wafer is then cleaned and subjected to a DSP process similar to that described in the first embodiment, except that more material is removed from the front surface than from the rear surface.

[0030] The DSP process of the second embodiment preferably removes almost all damage from the front surface while leaving some amount of damage on the rear surface. Damage sites on the rear surface contribute to gettering of the rear surface. The DSP device can be set to remove a significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com