Lutetium disilicate blended submicron imaging fluorescent sreen and its preparing method

A lutetium disilicate and phosphor screen technology is applied in the field of doped lutetium disilicate submicron imaging phosphor screens and their preparation, which can solve the problems of long light decay time, easy deliquescence of thin films, low coupling efficiency and the like, and achieve high X-ray absorption. coefficient, high quality single crystal film, good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the doped lutetium disilicate submicron imaging phosphor screen includes the following steps:

[0042] (1) Raw material equipment:

[0043] ①According to the chemical formula (Ce x M z Re y Lu 1-x-y-z ) 2 Si 2 O 7 , And select x, y, z, equipped with polycrystalline materials;

[0044] ②According to the following components, select the ratio and equip the flux raw materials:

[0045] Composition wt%

[0046] PbF 2 50-60

[0047] PbO 10-20

[0048] PbO 2 Or Li 2 Mo 2 O or K 2 Mo 2 O 7 20-40

[0049] ③According to polycrystalline raw material: flux raw material=10-40wt%, determine the weight percentage of the above-mentioned raw materials;

[0050] (2) Weigh the raw materials according to the weight percentage determined in step (1) above;

[0051] (3) Preparation of lutetium disilicate substrate: lutetium disilicate is oriented and cut into substrate wafers (Lu 1-y Re y ) 2 Si 2 O 7 (0≤y≤0.3) for large-area seed crys...

Embodiment 1

[0063] Example 1: (Ce 0.005 Lu 0.995 ) 2 Si 2 O 7 / Lu 2 Si 2 O 7 Flashing screen

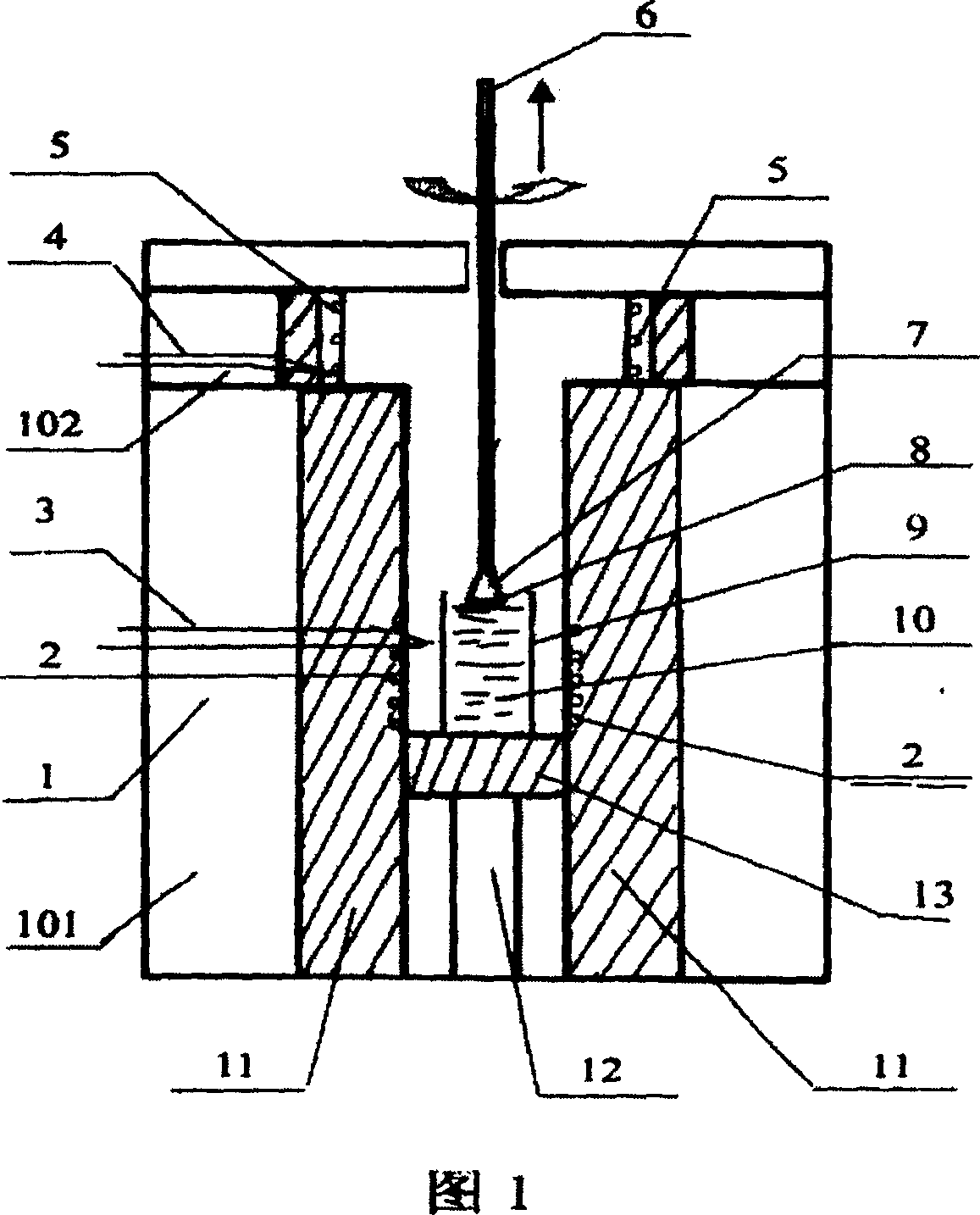

[0064] The selected resistance heating liquid phase epitaxy furnace is shown in Fig. 1, and the crucible 9 in the main furnace 101 is a platinum crucible. According to the above preparation process, the polycrystalline raw material (Ce 0.005 Lu 0.995 ) 2 Si 2 O 7 With cosolvent (PbF 2 :PbO:PbO 2 =55wt%: 15wt%: 30wt%) by weight percentage is (Ce 0.005 Lu 0.995 ) 2 Si 2 O 7 / (PbF 2 -PbO-PbO 2 )=0.10 to weigh the raw materials, a total of 500g, mix well and put them into the platinum crucible 9 of φ80×50mm; the size of φ30×0.03mm, the crystal plane direction is (010) Lu 2 Si 2 O 7 The substrate 8 is placed in the jig 7, and the jig 7 is loaded into the bottom end of the rotating pull rod 6, and the positions of the crucible 9 and the substrate wafer 8 are adjusted to be coaxial, and both are in the center of the main furnace body 101; 101 is heated to 1200°C, the raw materials and flux are melted into ...

Embodiment 2

[0066] Example 2: (Ce 0.001 In 0.1 Lu 0.899 ) 2 Si 2 O 7 / (In 0.1 Lu 0.9 ) 2 Si 2 O 7 Flashing screen

[0067] Will (In 0.1 Lu 0.9 ) 2 Si 2 O 7 Polycrystalline material and cosolvent Li 2 Mo 2 O 7 By weight percentage (Ce 0.001 In 0.1 Lu 0.899 ) 2 Si 2 O 7 / Li 2 Mo 2 O 7 =0.40, weighing a total of 500g of each raw material, the size is φ20×0.03mm, the crystal plane direction is (001) (In 0.1 Lu 0.9 ) 2 Si 2 O 7 The substrate 8 is placed in the jig 7, and the jig 7 is loaded into the bottom end of the rotating pull rod 6, and the positions of the crucible 9 and the substrate wafer 8 are adjusted to be coaxial, and both are in the center of the main furnace body 101; 101 is heated to 1200°C, the raw materials and flux are melted into a saturated solution 10, and after a constant temperature of 1200°C for 5 hours, the rotating lifting rod 6 is gradually lowered so that the substrate wafer 8 is 3mm away from the saturated liquid surface, and then the (Ce 0.001 In 0.1 Lu 0.899 ) 2 Si 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com