Uniterruption power supply unit, changer and parallet work type changer

A power supply device and power conversion technology, which is applied to battery circuit devices, circuit devices, output power conversion devices, etc., and can solve problems such as increased load sharing of converters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

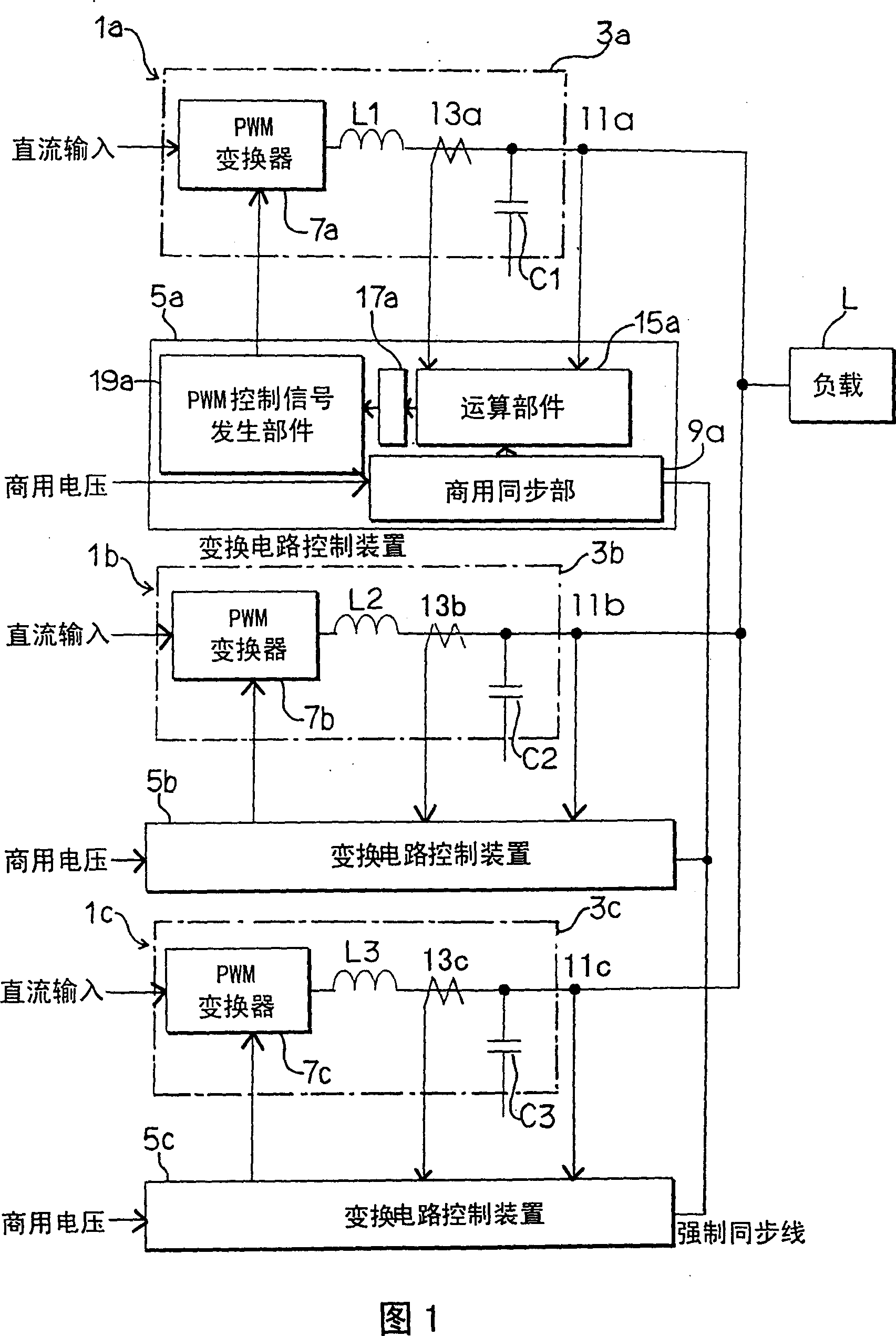

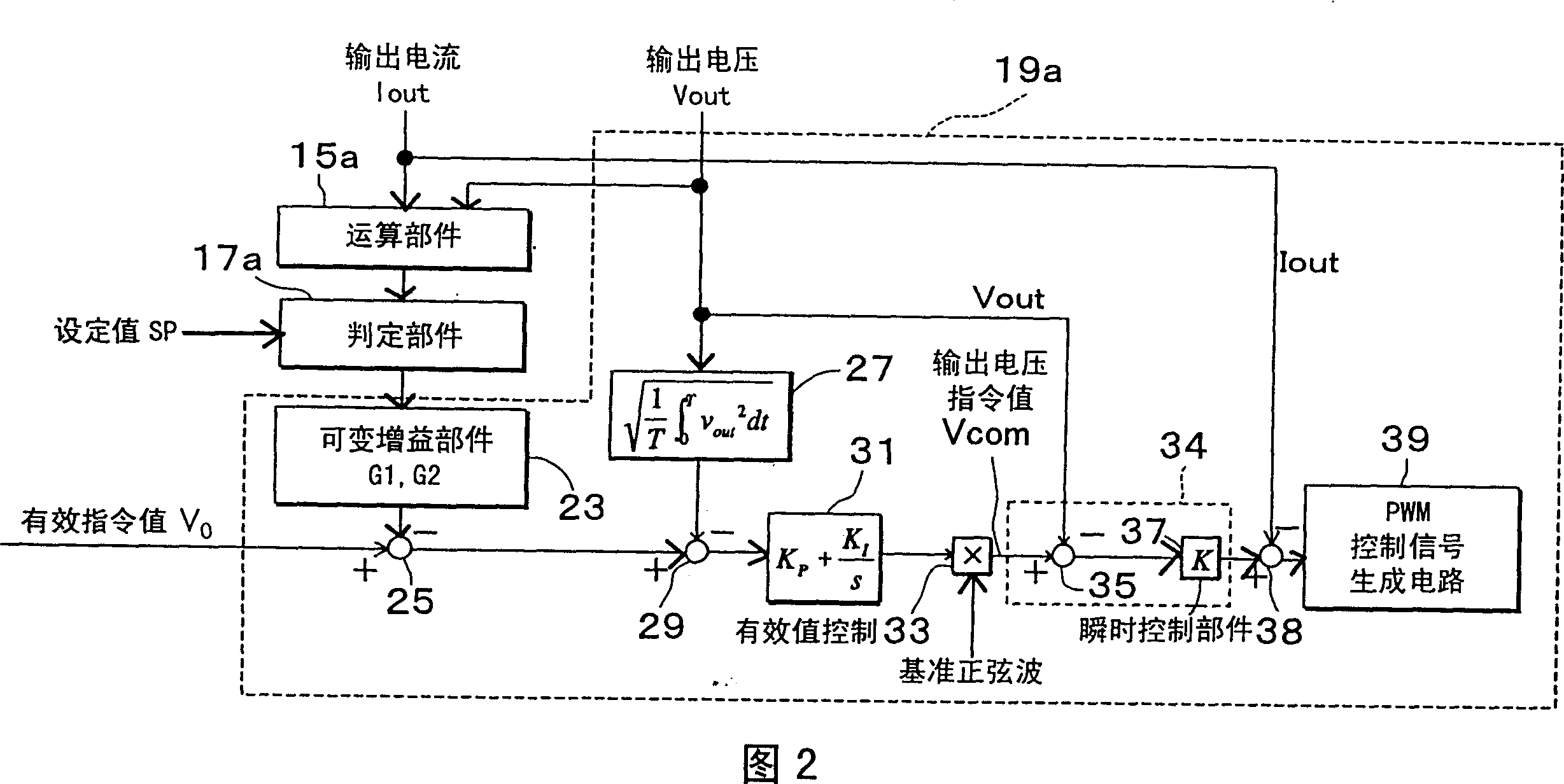

[0019] Embodiments of the present invention will be described below with reference to the drawings. FIG. 1 is a block diagram showing a configuration of an embodiment in a case where three uninterruptible power supply devices including the conversion device of the present invention are connected in parallel. Furthermore, FIG. 2 is a block diagram showing a detailed configuration of the converter circuit control device in FIG. 1 . In these figures, uninterruptible power supply devices 1a, 1b, 1c are composed of conversion circuits 3a, 3b, 3c and conversion circuit control devices 5a, 5b, 5c, and the outputs of these three uninterruptible power supply devices 1a, 1b, 1c are respectively Connect the load.

[0020] The conversion circuits 3a, 3b, 3c include: PWM converters 7a, 7b, 7c for PWM control formed by connecting a plurality of semiconductor switching elements in a bridge type; reactance coils L1, L2 connected in series to the PWM converters 7a, 7b, 7c , L3 and capacitors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com