A method for automatically calibrating the received power of a sensor by a sensor test system

A test system and automatic calibration technology, applied in transmission monitoring/test/fault measurement systems, optical fiber transmission, etc., can solve the problems of low calibration accuracy, complicated operation, and high labor cost, achieve flexible operation, wide application prospects, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

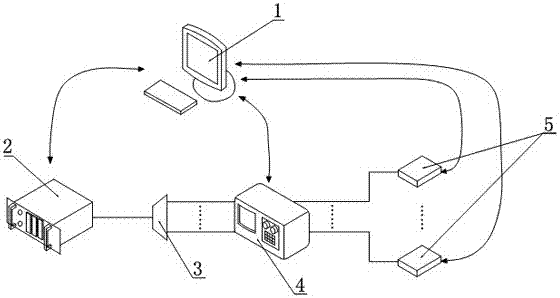

[0043] Such as figure 1 As shown, the present invention provides a BOB module testing system, which includes a host computer 1 , an optical line terminal 2 , an optical splitter 3 , an integrated identification system 4 and a BOB module 5 . The optical line terminal 2, the integrated identification system 4 and the BOB module 5 are all connected to the host computer 1 through the Eth interface. The integrated identification system 4 is integrated with an optical attenuator, and the model of the integrated identification system 4 is preferably IQS-600 or IQS-610, while the model of the integrated optical attenuator is preferably IQS-3150. The optical splitter 3 is simultaneously connected to the optical line terminal 2 and the optical attenuator through an optical fiber, and the BOB module 5 is connected to the optical attenuator through an optical fiber, and in this embodiment, the optical splitter 3 is a 1×8 optical splitter , and there are eight BOB modules 5 and eight opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com