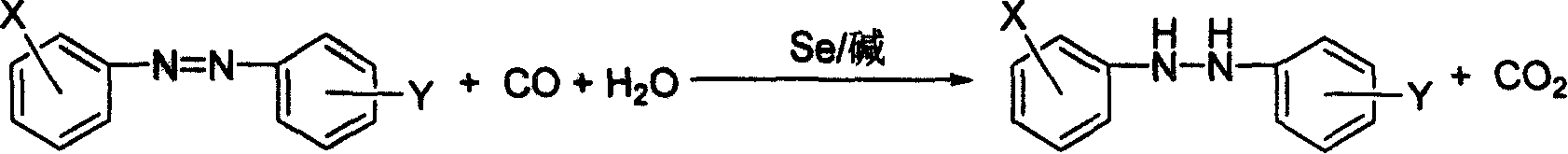

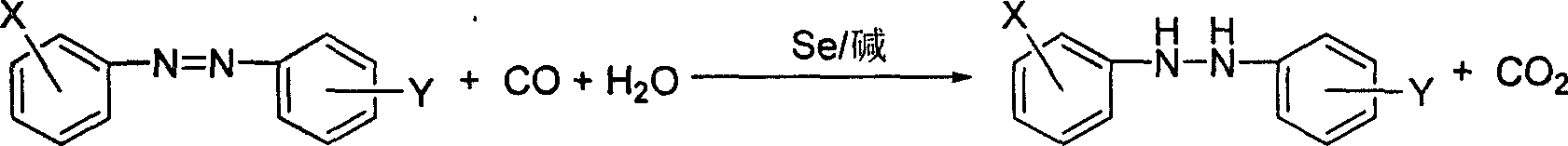

Method of synthesizing hydrodiazo kind compound

A technology for the hydrogenation of azo compounds, applied in the field of synthesis of azobenzene compounds, which can solve the problems of reaction by-product pollution, high cost, and no reduction of azo groups, and achieve simple raw materials, low cost, and subsequent separation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add azobenzene 9.1g (50mmol), Se0.08 (1mmol), H 2 O 9g (0.5mol), triethylamine 0.5g (5mmol) and solvent DMF200mL (2.6mol), continue to pass carbon monoxide, then heat to 88 ° C and stir for 0.5 hours, cool to room temperature, switch carbon monoxide to oxygen or air After stirring for 0.5-1 hour, filter out the selenium powder according to a conventional method. The solvent was evaporated by distillation under reduced pressure (below 5kPa), washed with water, and filtered. The yield was 95%.

Embodiment 2

[0023] temperature(°C)

Embodiment 3

[0025] solvent

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com