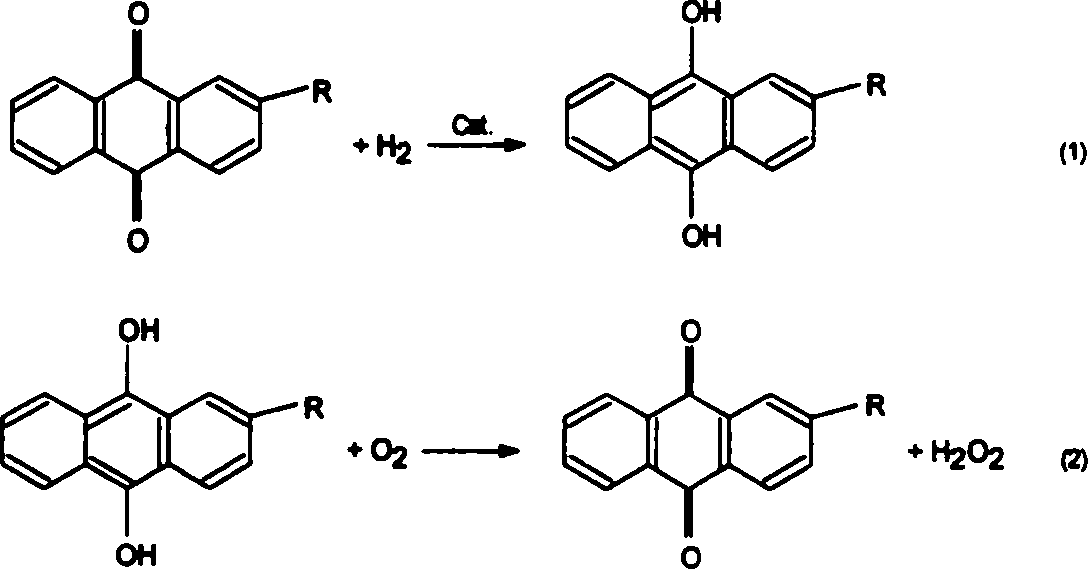

Operation process for hydrogenation reaction of anthraquinone work liquid during hydrogen perioxide production

A technology of hydrogenation reaction and operation method, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the reaction conversion rate and selectivity Low, low selectivity, uneven radial distribution, etc., to achieve the effect of improving conversion and selectivity, improving catalyst utilization, and improving wetting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1 The inner diameter of the reactor is φ21mm, the height is 650mm, Pd / Al 2 o 3 The diameter of the catalyst is 1.9mm, the hourly average flow rate of the working fluid is 10mL / min, the flow rate of hydrogen is 45mL / min, the operating temperature of the reactor is 60°C, and the pressure is 300kPa. The results of the hydrogenation reaction are shown in Table 1.

[0013] operation method

Embodiment 2

[0014] Example 2 uses the same reactor as above, the hourly average flow rate of the working fluid is 5mL / min, the flow rate of hydrogen is 45mL / min, the operating temperature of the reactor is 60°C, and the pressure is 250kPa. The performance comparison between continuous feeding and periodic feeding fixed bed reactor is shown in Table 2.

[0015] operation method

[0016] As can be seen from the data in the table, the conversion rate and selectivity of the reactor are significantly improved by adopting the fixed-bed reactor operation method of the present invention to carry out the hydrogenation reaction of anthraquinone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com