Bobbin for spinning

A yarn bobbin and tube sleeve technology, applied in the field of textile machinery, can solve the problems of reducing wet spraying efficiency and unreliable yarn processing, etc., and achieve the effects of reducing production costs, saving resources, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

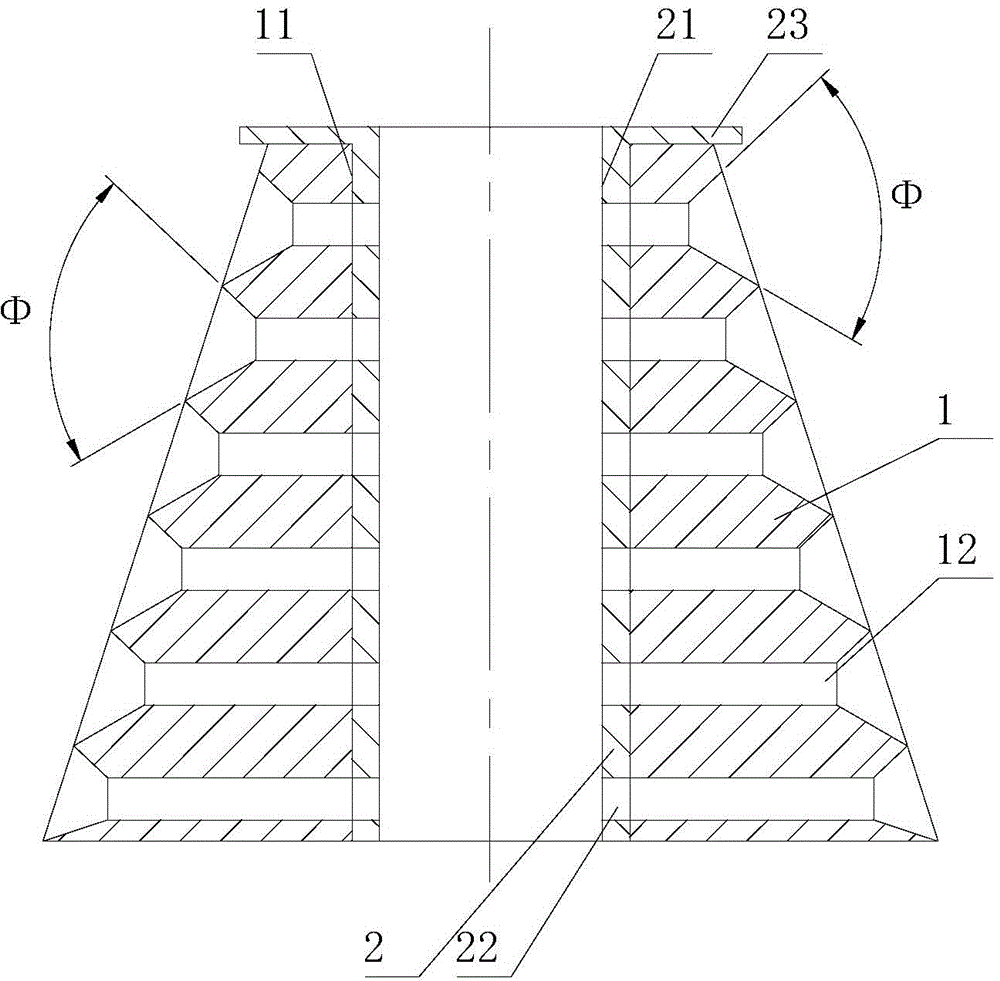

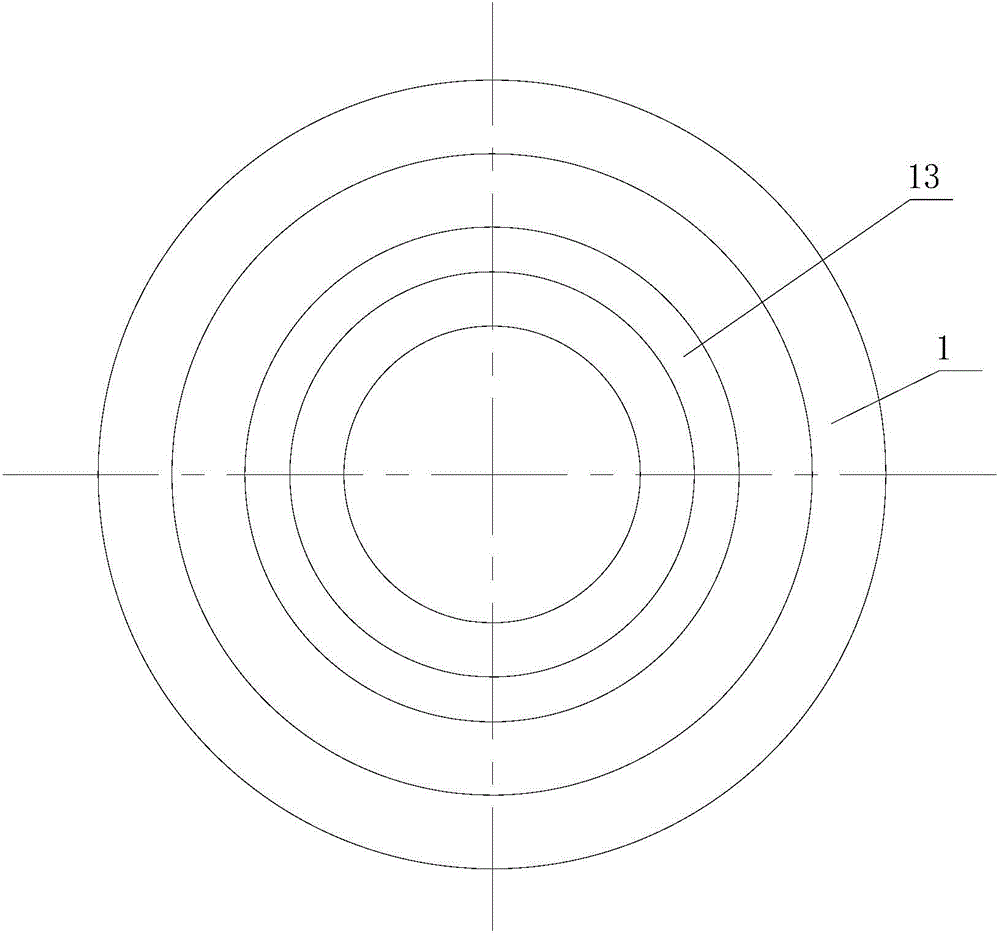

[0017] Such as figure 1 As shown, a bobbin for textiles comprises a conical tube body 1, the middle part of the conical tube body 1 is provided with a tube body installation hole 11 along the axial direction, and a detachable sleeve is set inside the tube body installation hole 11. 2. The sleeve 2 is provided with a sleeve installation hole 21 along the axial direction, and the sleeve installation hole 21 is used in conjunction with the spindle of the textile machine; Moisture spray holes 12, each spray hole 12 includes a straight-through hole close to the pipe body mounting hole 11 and a trumpet-shaped hole close to the outside of the tapered pipe body 1 and flared outwards, the straight-through hole communicates with the trumpet-shaped hole, and the horn The opening angle Φ of the shaped hole is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com