Method for preparing carbon gas gel

A carbon aerogel and aerogel technology, which is applied in the field of preparation technology of atmospheric drying method, can solve the problems of carbon particle size and porosity damage, nano-particle structure collapse, etc., and achieves shortened preparation time, simple process and equipment, The effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

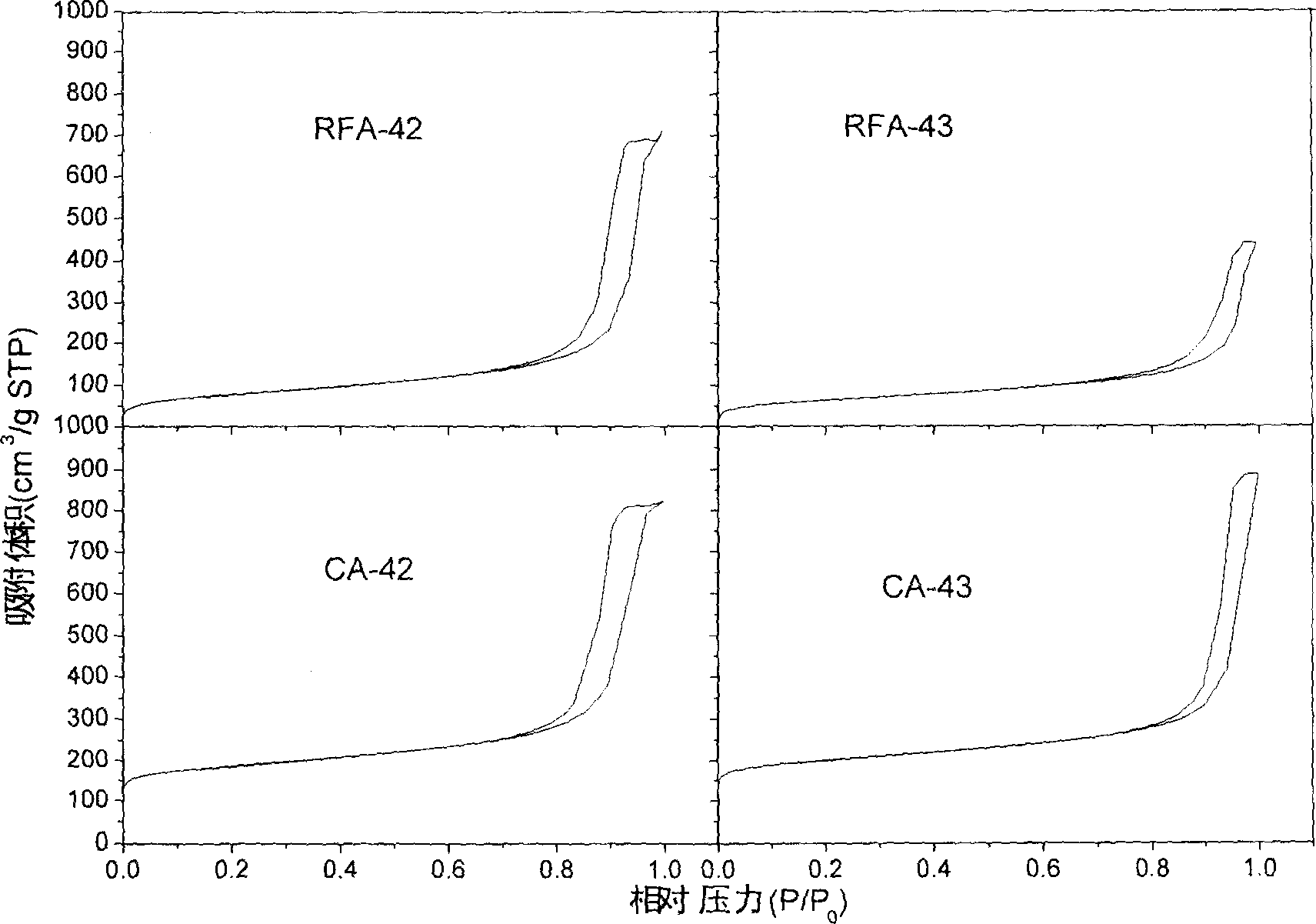

Embodiment 1

[0019] Embodiment 1: according to R / F=0.5, R / C=100 (C is hexadecyltrimethylammonium bromide), RF%=40wt%, with 1 gram of resorcinol, 1.26 milliliters of aqueous formaldehyde ( 37~40wt%, the formula is calculated with 38.5wt% in this paper), 0.0331 grams of cetyltrimethylammonium bromide and 1.46 milliliters of distilled water are mixed and stirred evenly, then poured into an ampoule bottle and sealed, reacted at 85°C The hydrogel was obtained in 5 days; then dried naturally in the air for half a day, dried with an infrared lamp (drying position at about 60°C) for 5 hours, and then placed in an oven (110°C) for final drying and dehydration for 5 hours to obtain an organic aerosol glue. The measured density of the organic airgel is 0.452g cm -3 , with a theoretical density of 0.449g cm -3 Very close; BET specific surface area is 282m 2 g -1 , mesopore volume 1.1cm 3 g -1 , The mesopore diameter is about 18nm.

Embodiment 2

[0020] Embodiment 2: According to R / F=0.5, R / C=200 (C is sodium dodecylsulfonate), RF%=40wt%, with 1 gram of resorcinol, 1.26 milliliters of formaldehyde aqueous solution, 0.0124 gram of ten Sodium dialkylsulfonate and 1.46 milliliters of distilled water were mixed and stirred evenly, then poured into an ampoule bottle and sealed, and reacted at 85° C. for 1 day to obtain a hydrogel; then naturally dried in air for 1 day, and dried by an infrared lamp ( The drying position is about 60°C) for 5 hours, and then placed in an oven (110°C) for final drying and dehydration for 5 hours to obtain an organic airgel. The measured density of the organic airgel is 0.452g cm -3 , with a theoretical density of 0.448g cm -3 very close. The BET specific surface area is 227m 2 g -1 , mesopore volume 0.52cm 3 g -1 , The average pore size is 10.6nm.

Embodiment 3

[0021] Embodiment 3: According to R / F=0.5, R / C=100 (C is tetrabutylammonium bromide), RF%=40wt%, with 1 gram of resorcinol, 1.26 milliliters of formaldehyde aqueous solution, 0.0293 gram of tetrabutylammonium Ammonium bromide and 1.46 ml of distilled water were mixed and stirred evenly, then poured into an ampoule bottle and sealed, reacted at 85°C for 5 days to obtain a hydrogel; then dried naturally in the air for half a day, and dried with an infrared lamp (drying position about 60°C) for 5 hours, and then placed in an oven (110°C) for final drying and dehydration for 5 hours to obtain an organic airgel. The measured density of organic airgel is 0.559g cm -3 , with a theoretical density of 0.448g cm 3 closer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com