Method for mfg. electric connector containing multi-conducting terminals and metal frame by plugging shaping method

A technology of conductive terminals and metal frames, which is applied in the field of insert molding to manufacture an electrical connector including multiple conductive terminals and metal frames, which can solve the problem that the contact parts of conductive terminals are difficult to maintain on the same plane, terminal spacing or coplanarity Changes, reduced connector precision and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

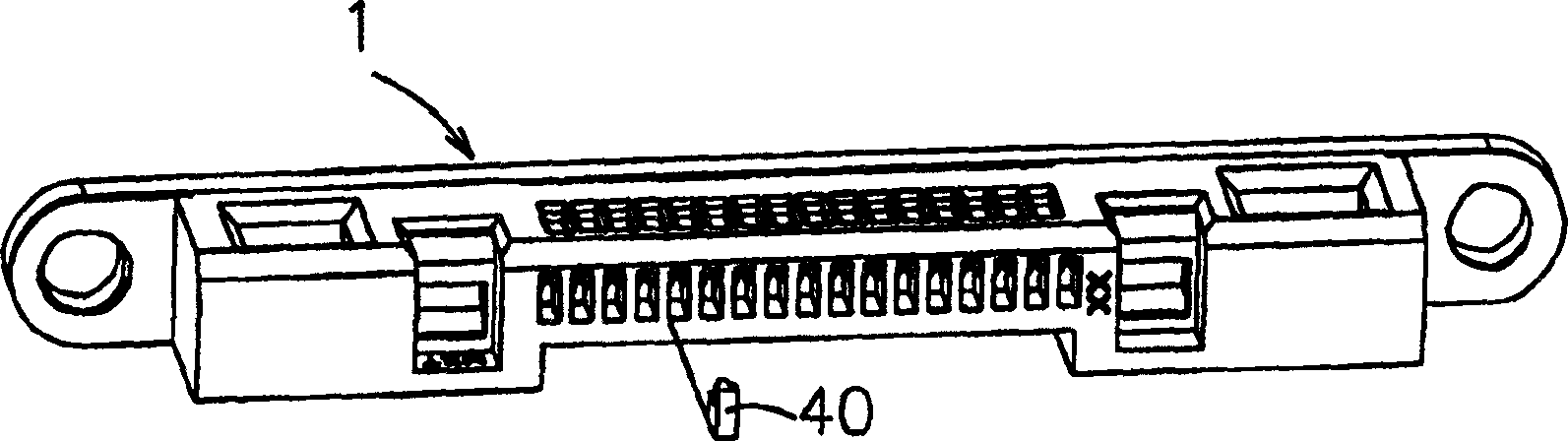

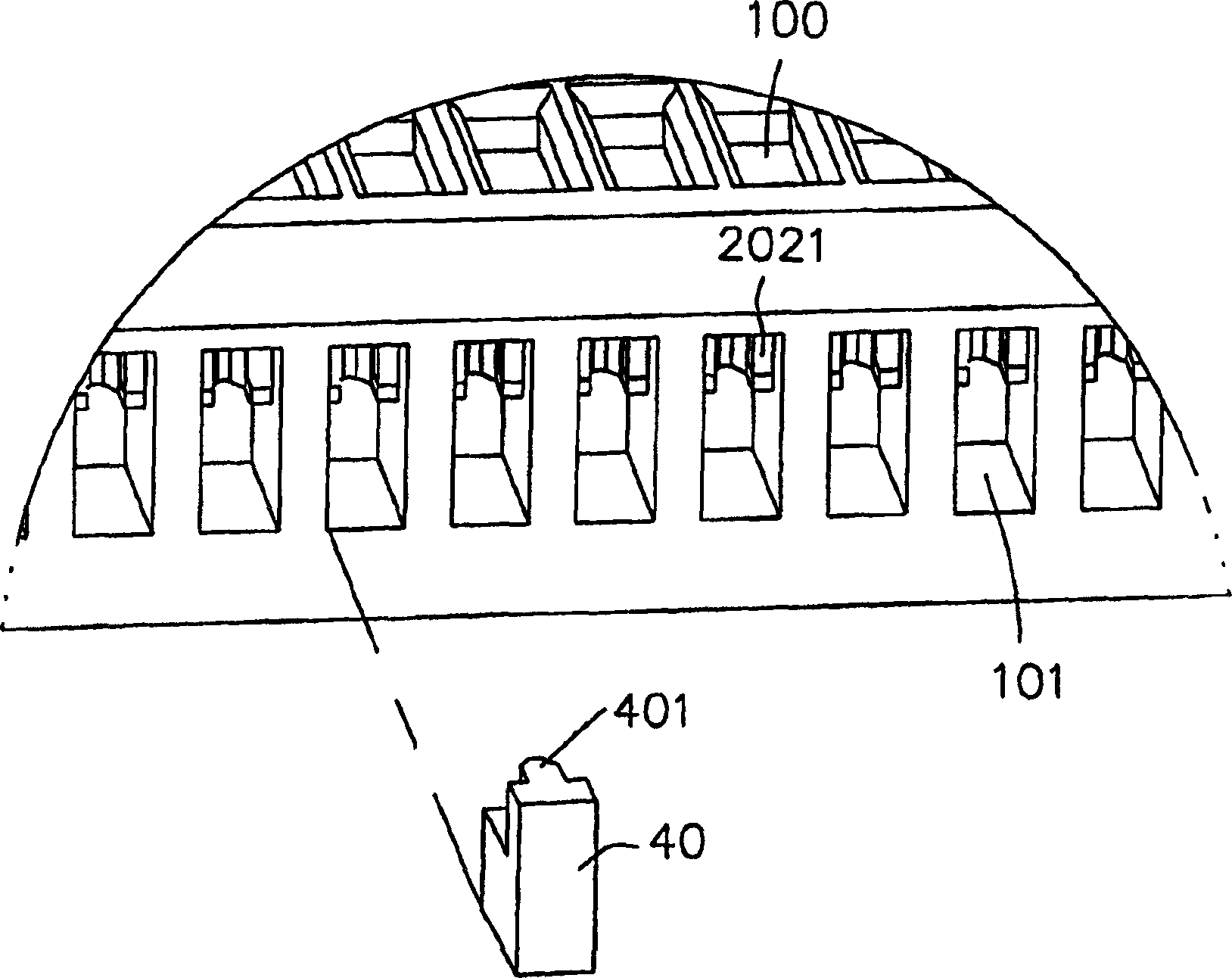

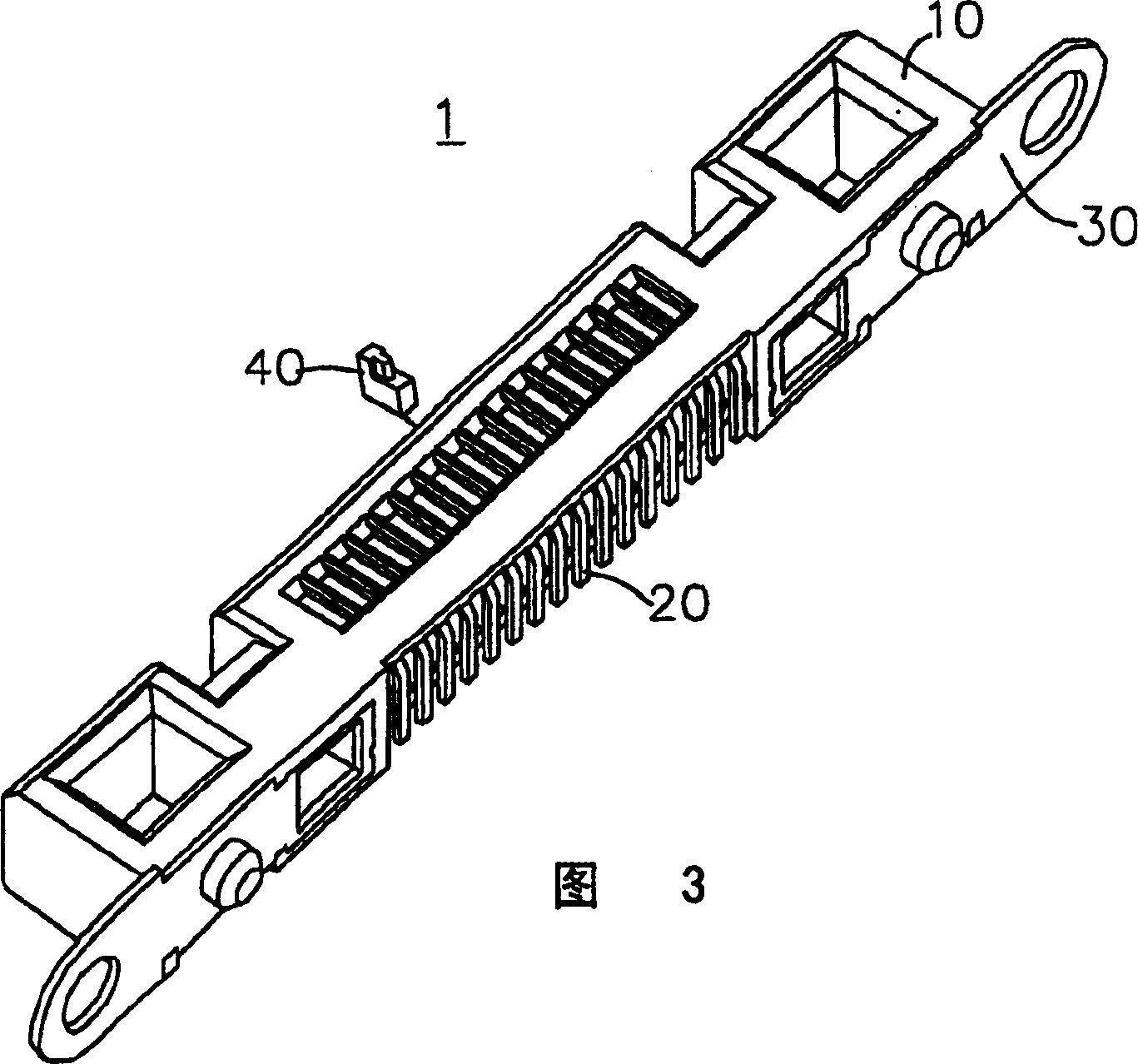

[0022] The following will illustrate the implementation of the present invention by a preferred embodiment. see you first figure 1 -4, wherein Fig. 4 shows the position state of the conductive terminal 20 and the metal frame 30 when placed in the mold cavity as the core during insert molding, figure 1 , 3 is the connector 1 after the insulating shell has been formed. It can be seen from the two figures that, except for the surface that can be welded on the circuit board, the insulating shell 10 surrounds most of the surfaces of the conductive terminal 20 and the metal frame 30, and Slots 100 are formed corresponding to the contact portions 202 of the terminals, so that the mating connector can be electrically connected to the contact portions 202 .

[0023] figure 1 It is the connector 1 and a terminal part holder 40 in a separated state, that is, in the position shown in this figure, the connector 1 is plugged with the mating connector facing upward. As shown in Figure 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com