Device and method for acid exciting of underwell structure layer

A stratum and equipment technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as reducing hydrostatic effect, large friction coefficient of foam, and increasing pressure required for treatment wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

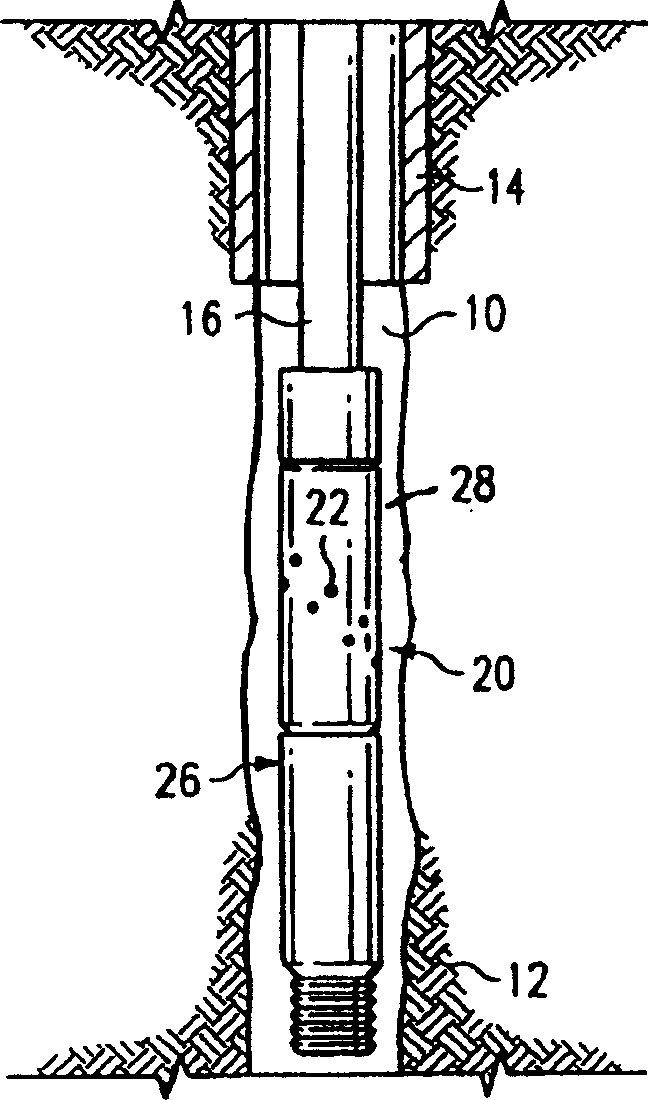

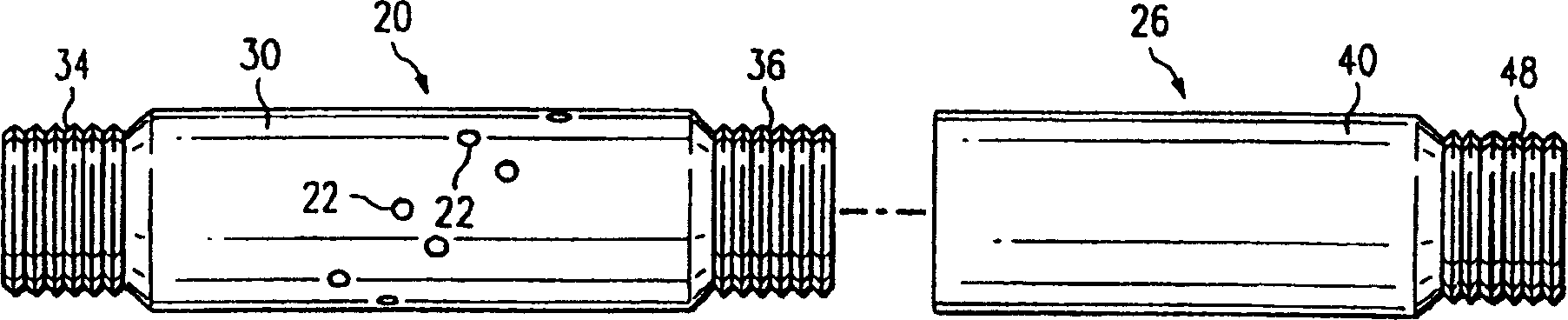

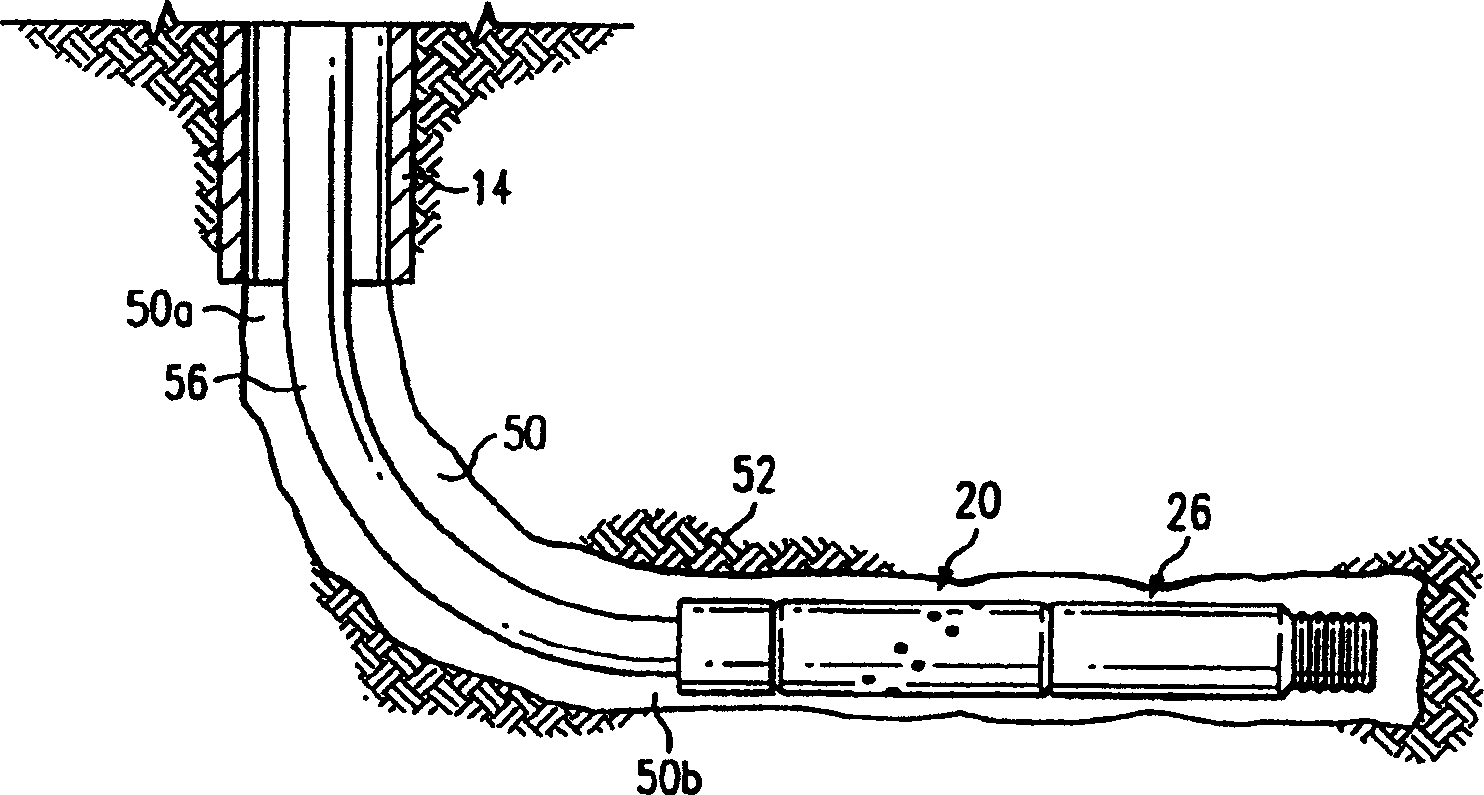

[0015] refer to figure 1 , shows a stimulation device according to an embodiment of the present invention installed in an underground vertically extending wellbore 10 penetrating a subterranean formation 12 producing hydrocarbons. A casing 14 extends from the surface (not shown) into the wellbore 10 and terminates above the formation. The stimulation apparatus includes a working string 16 in the form of tubing or coiled tubing extending from the surface through the casing 14 . as from figure 1 As seen in , a working string 16 extends beyond or below one end of the casing 14, and one end of the working string 16 is coupled to one end of a tubular spray sub 20 in a manner to be described. The jet fitting has a plurality of through-holes 22 machined through its wall, forming discharge jets as will be described in detail below.

[0016] A valve connector 26 is coupled to the other end of the spray connector 20 in a manner that will also be described. As will be described in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com