Organic fertilizer composed of waste liquid and waste residue and decomposing leaven from sugar refinery and method for preparing the same

A technology for organic fertilizer and sugar factory waste liquid, which is applied in the preparation of organic fertilizer and organic fertilizer, and the treatment of biological organic parts, etc., can solve the problems of high production cost, complex process, low effective bacterial count, etc. Low investment, wide pH adaptation range, improved quantity and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

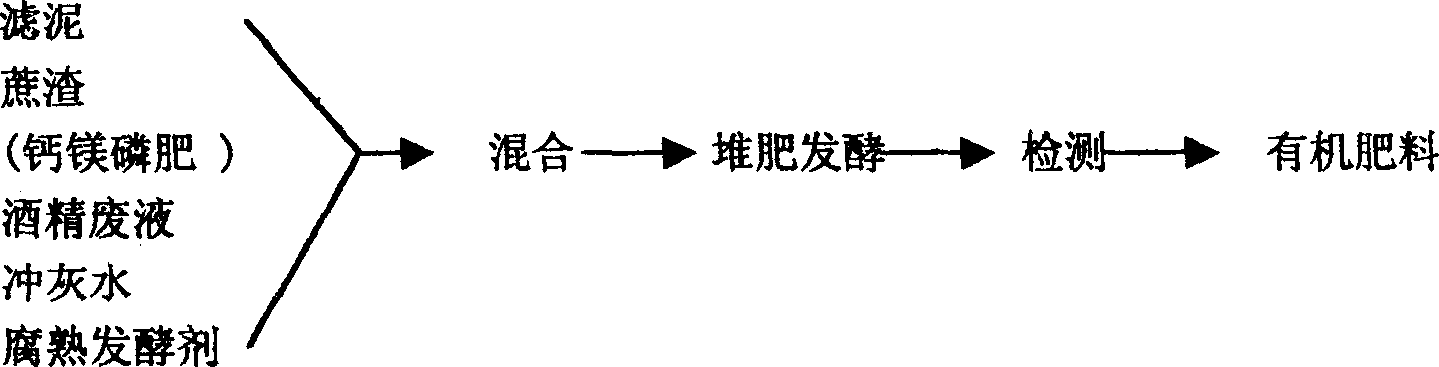

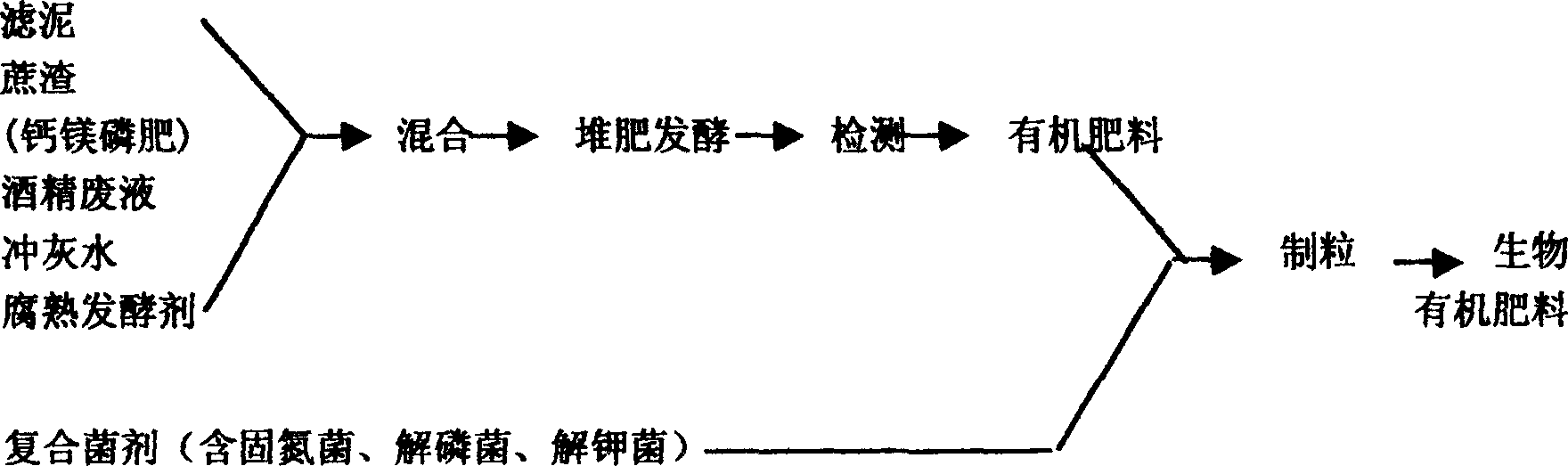

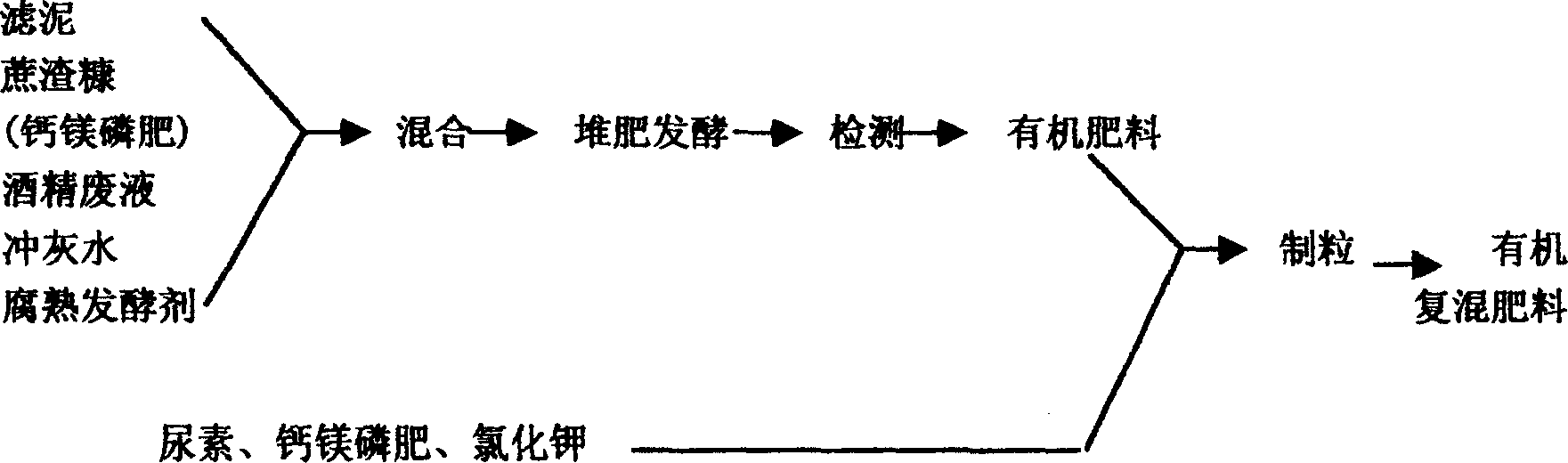

Method used

Image

Examples

Embodiment 11

[0038] Embodiment 1.1: the organic fertilizer of the present invention is made up of fermented material and decomposed fermenting agent; Fermented material component and weight ratio are determined in the following range: molasses alcohol waste liquid or / and ash flushing water are 10~82%, bagasse or / and The filter mud is 18-90%, and the rest is straw, peat soil, animal manure, inorganic fertilizer, soil or a combination thereof, and the weight is 0-15%; the decomposed starter contains cellulolytic bacteria, hemicellulose Decomposing bacteria, proteolytic bacteria, and starch-decomposing bacteria are mixed by seed koji; the weight of the decomposed starter is less than or equal to 2% of the weight of the fermented material; the bacteria contained in the decomposed starter described in this embodiment are Aspergillus niger, green Combination of 2 to 5 species of Trichoderma, Endospora cystis, Bacillus subtilis, and Saccharomyces cerevisiae.

Embodiment 12

[0039] Embodiment 1.2. The difference between the organic fertilizer described in this embodiment and Embodiment 1.1 is that the fermentation material components and weight ratio are: molasses alcohol waste liquid 10%, bagasse 90%; the strains contained in the decomposed starter are: green wood Mildew, Endospora cystis, Bacillus subtilis, Saccharomyces cerevisiae, the number of bacteria contained in each koji is 2 to 2 billion / g; the weight of the decomposed starter is 0.01% of the weight of the fermented material.

Embodiment 13

[0040] Embodiment 1.3: The difference between the organic fertilizer described in this embodiment and Embodiment 1.1 is that the composition and weight ratio of the fermented material are: alcohol waste liquid and ash flushing water are 82% in total, filter mud and bagasse are 18% in total; the decomposed fermentation agent contains The strains of the strain are Endospora cystis and Bacillus subtilis, the number of bacteria contained in each strain is a conventional number, and the weight of the decomposed starter is 2% of the weight of the fermented material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com