Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

A technology of circulating fluidized bed and steam injection boiler, which is applied in the direction of fluidized bed combustion equipment, the combustion of lump fuel and liquid fuel, and the fuel burned in the molten state to achieve the effect of suppressing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

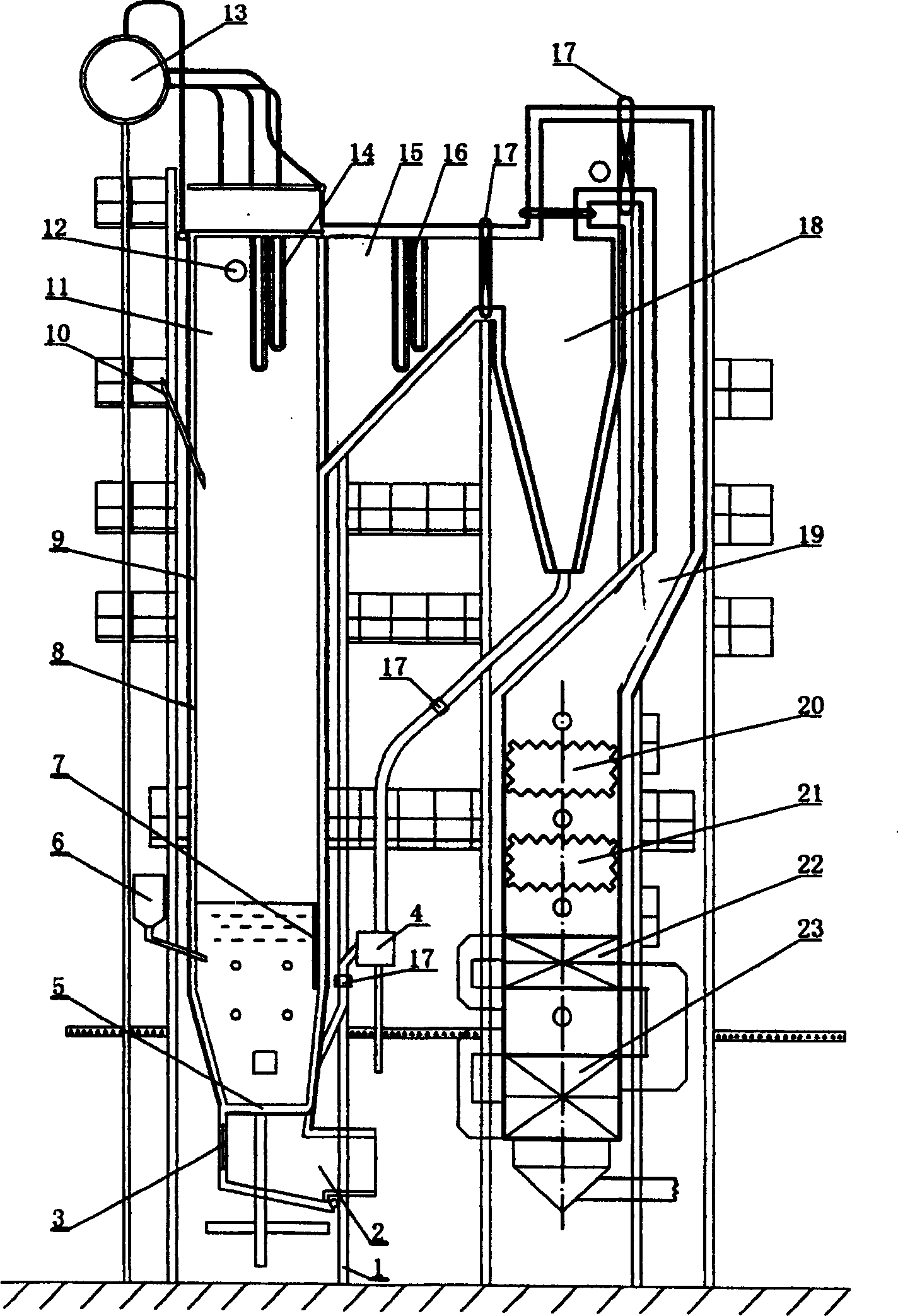

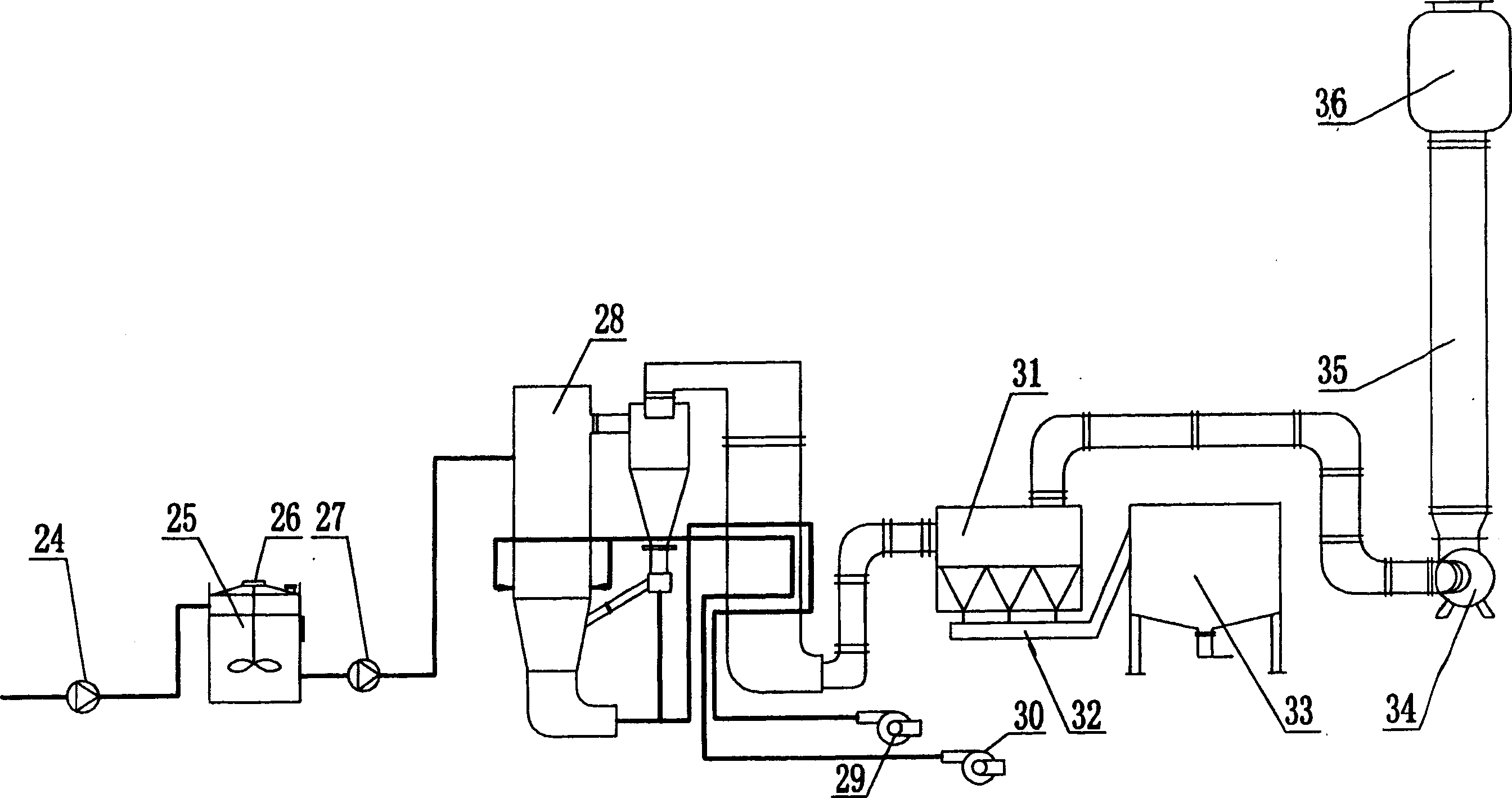

[0038] The present invention has been used to produce 17.5MPa pressure, rated evaporation of 7t / h, 10t / h, 15t / h, 20t / h, 25t / h circulating fluidized bed oil field steam injection boilers using coal water slurry as fuel. Only take the 20t / h boiler as an example to illustrate the implementation of the present invention:

[0039] (1) Use of fuel

[0040] Coal water slurry meeting GB / 718855-2002 standard: solid phase concentration 66%, viscosity: 1.2pas, coal powder average particle size d50: 38-45μm, ash content: 6%, sulfur content: 0.35%, volatile content > 30% , calorific value 20935k J / kg.

[0041] (2) The 20t / h, 17.5MPa circulating fluidized bed oil field steam injection boiler with coal-water slurry as fuel manufactured according to the boiler structure described in the content of the present invention is supplied from the upper part of the boiler body with a high position to the furnace by a screw pump Coal water slurry, the water supply coal slurry pressure is 0.3MPa; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com