Method for dissolution of nitrogen-rich inclsions in titanium and titanium alloy

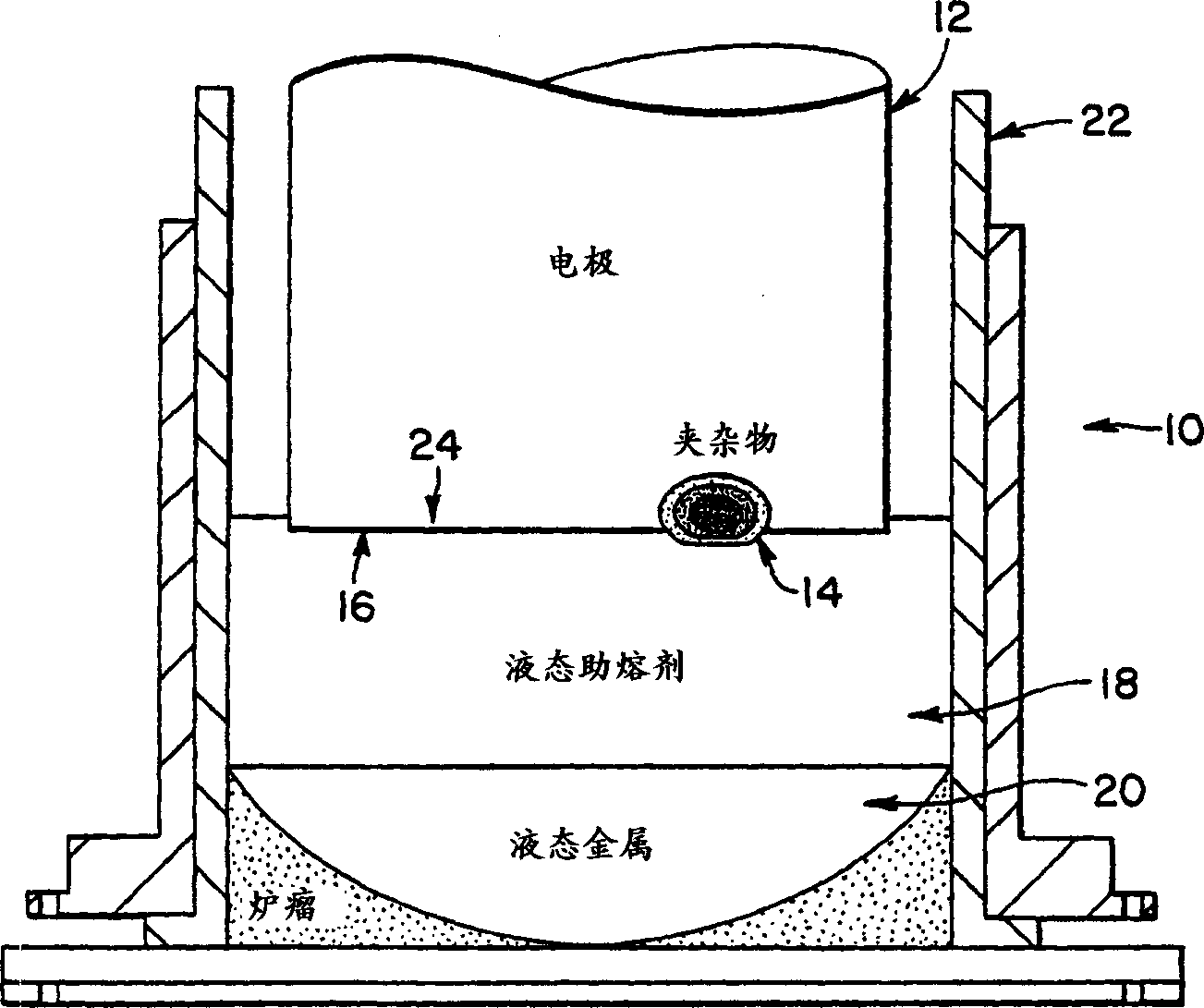

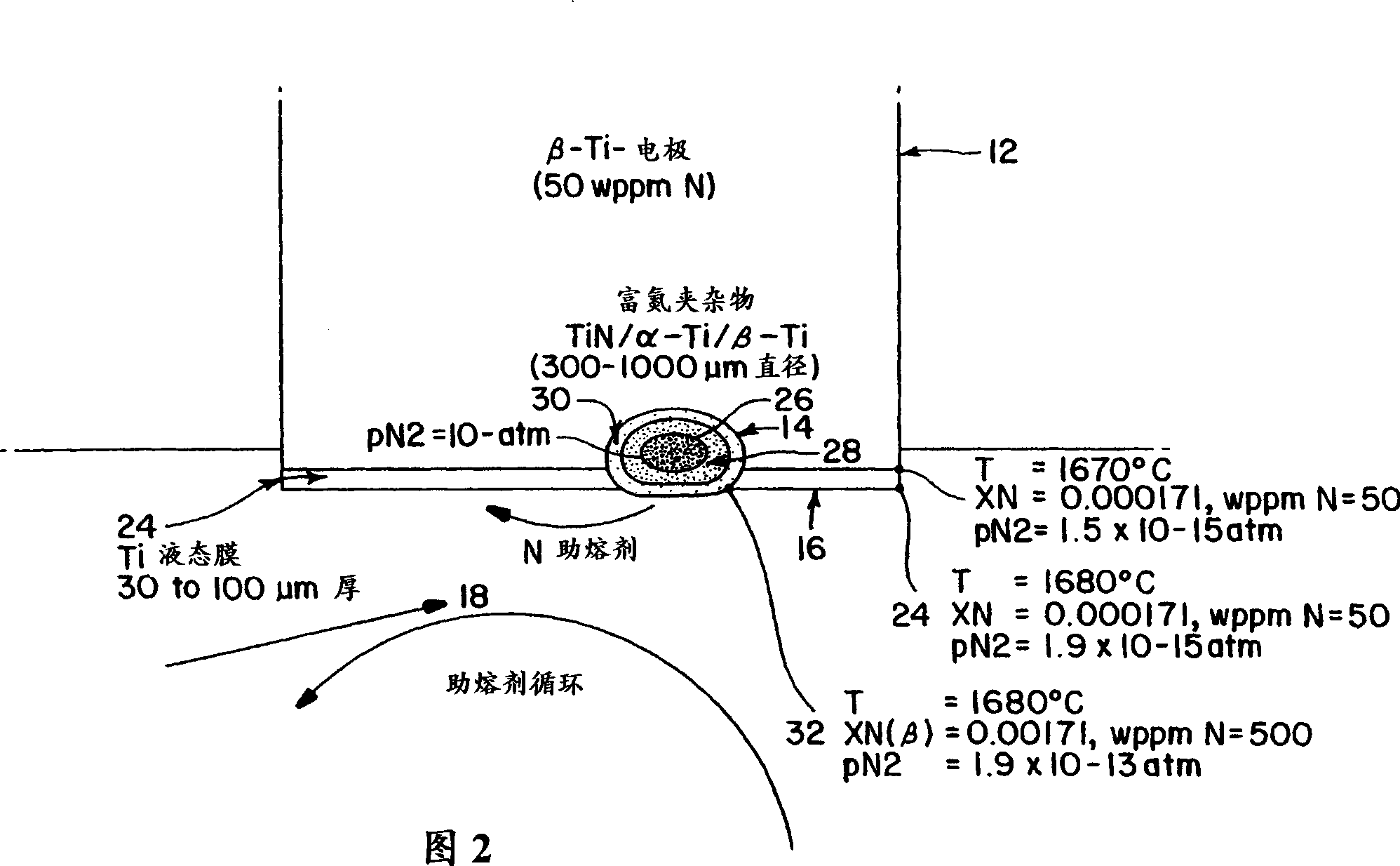

An inclusion, titanium alloy electrode technology, applied in the field of electroslag remelting and halide flux to remove nitrogen-rich inclusions, can solve problems such as expensive and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Observed in the laboratory titanium nitride (TiN) and the mutual reaction of the flux that is base material with calcium fluoride, during observation, immerse 70% Calcium Fluoride (CaF 2 ), 15% calcium oxide (CaO) and 15% aluminum oxide (Al 2 o 3 ) in the flux. The flux is heated by induction heating in a graphite crucible. Melting of titanium nitride (TiN) was seen.

Embodiment 2

[0033] Example 2: Inclusion Preparation - Two types of inclusions were prepared using GE-CRD. The inclusion numbered 30 was prepared by placing nitrided sponge and titanium powder in multiple titanium alloy tubes. These tubes are sealed by electron beam welding with tube plugs. The tubes were then isostatically pressed at 1200°C / 1000 atm / 4 hours. Samples 12.5 mm in diameter and 10 mm in length were cut from these tubes. The nitrogen-containing portion of each sample was 10 mm in diameter.

[0034] The inclusion numbered 49 is prepared by placing titanium nitride powder in multiple titanium alloy tubes. These tubes are sealed by electron beam welding with tube plugs. The tubes were then isostatically pressed at 1200°C / 1000 atm / 4 hours. Samples 12.5 mm in diameter and 10 mm in length were cut from these tubes. The nitrogen-containing portion of each sample was 10 mm in diameter.

[0035] Information on inclusions is summarized in Part I of Schedule 1.

[0036] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com