Three-phase three-dimensional electrode photoelectric catalytic reactor and application thereof

A technology of reactors and reactor shells, applied in the field of three-phase three-dimensional photocatalytic reactors, to achieve a comprehensive effect of degradation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

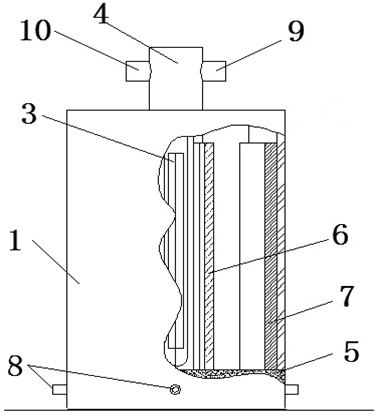

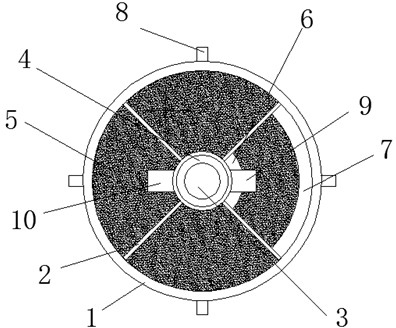

[0034] A three-phase three-dimensional electrode electro-photoelectric reactor, its structure schematic diagram is as follows figure 1 As shown, it includes a reactor shell 1, a metal titanium mesh anode 6, a stainless steel cathode 7, a gas distribution plate 5, a double-layer U-shaped quartz tube 4 and a light source UV lamp 3 placed in the quartz tube, a three-dimensional particle electrode and a spacer. board 2;

[0035] The metal titanium mesh 6 is used as the anode, and the aperture of the mesh is 6-8mm in order to ensure the light transmittance; the stainless steel 7 is used as the cathode, and the metal titanium mesh anode 6 and the stainless steel cathode 7 are connected to the electric connector of the DC power supply. Each reaction chamber is equipped with metal titanium mesh 6 anodes, and the metal titanium mesh anode titanium mesh of each reaction chamber is connected with a wire at the top;

[0036] The light source UV lamp 3 is placed in the inner tube of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com