Technology for recovering ash water of coal-fired power plant and system of sealing circulating for recovering thereof

A coal-fired power plant and circulation system technology, applied in water supply equipment, water supply equipment, descaling and water softening, etc., can solve the problems of ash conveying pipelines and return water pipelines, such as fouling and return water reuse rate, and achieve low cost, Strong operability and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

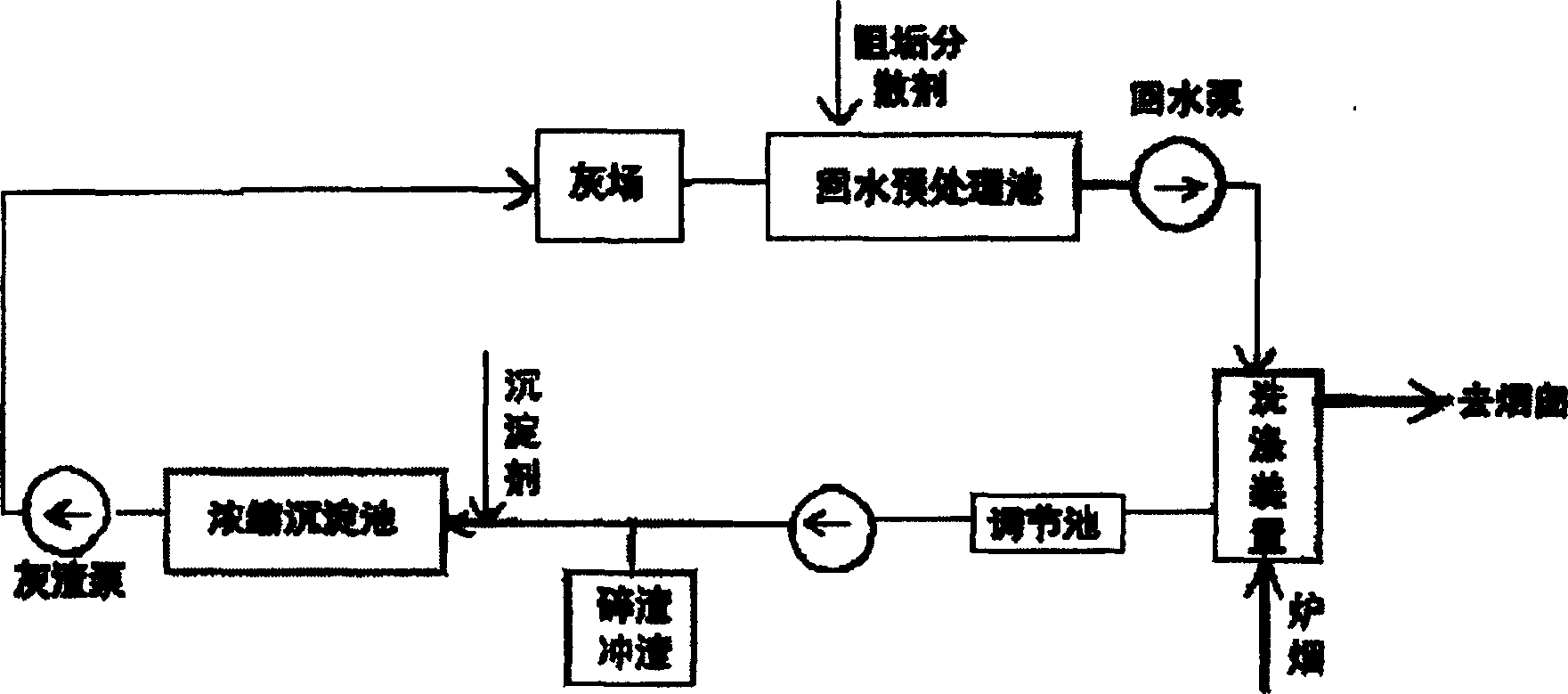

[0018] like figure 1 and figure 2 In the ash water reuse process of coal-fired power plants and its closed circulation system, after washing, the ash water from the washing tower first enters the adjustment tank, then removes debris, and then settles, that is, before entering the concentration sedimentation tank Add 15mg of precipitant to the ash water, after complexation and sedimentation, the ash pump will transport the mortar to the ash field through the ash delivery pipe, and then separate the ash and water, that is, add 1-2mg / L polyacrylamide in the ash field for flocculation After settlement, the return water from the ash yard is pretreated first, that is, the backwater first enters the backwater pretreatment tank between the ash yard and the washing tower, and at the same time, 3mg of scale inhibitor and dispersant is added per liter of backwater, and the backwater Under the action of anti-scaling and dispersing agent, the return water is pumped to the washing tower f...

Embodiment 2

[0023] Precipitating agent and antiscaling and dispersing agent are prepared according to the following weight percentages:

[0024] Precipitating agent: sodium humate 18%, trisodium citrate 5%, lignosulfonate 7%, sodium carbonate 62%, sodium bicarbonate 4% and sodium hydroxide 4%.

[0025] Antiscalant dispersant: N-phosphonic acid-N-sulfonic acid-N'-dicarboxyethylenediamine 10%, 2-phosphonobutane-1,2,4-tricarboxylic acid 20%, acrylic acid , 2-acrylamido-2-methylpropanesulfonic acid, 2-hydroxy-2-phosphonoacetic acid and phosphonic acid tetrapolymer 40% and distilled water 30%.

[0026] The dosage of precipitant is 10mg / L, the dosage of antiscalant and dispersant is 2mg / L, the others are the same as Example 1, and will not be repeated. The results are shown in Table 1.

Embodiment 3

[0028] Precipitating agent and antiscaling and dispersing agent are prepared according to the following weight percentages:

[0029] Precipitating agent: sodium humate 16%, trisodium citrate 6%, lignosulfonate 8%, sodium carbonate 64%, sodium bicarbonate 3% and sodium hydroxide 3%.

[0030] Antiscalant dispersant: N-phosphonic acid-N-sulfonic acid-N'-dicarboxyethylenediamine 15%, 2-phosphonobutane-1,2,4-tricarboxylic acid 30%, made of acrylic acid , 2-acrylamido-2-methylpropanesulfonic acid, 2-hydroxy-2-phosphonoacetic acid and phosphonic acid tetrapolymer 30% and distilled water 25%.

[0031] The dosage of precipitant is 12mg / L, the dosage of antiscalant and dispersant is 1mg / L, and the washing device is a water film dust collector. Others are the same as in Example 1 and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com