Method for adjusting and controlling character of mixed liquor in membrane bioreactor for controlling membrane pollution

A technology of mixed liquid and membrane control, applied in chemical instruments and methods, biological water/sewage treatment, oxidized water/sewage treatment, etc. The water quality is stable, the structure is compact, and the effect of improving membrane filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

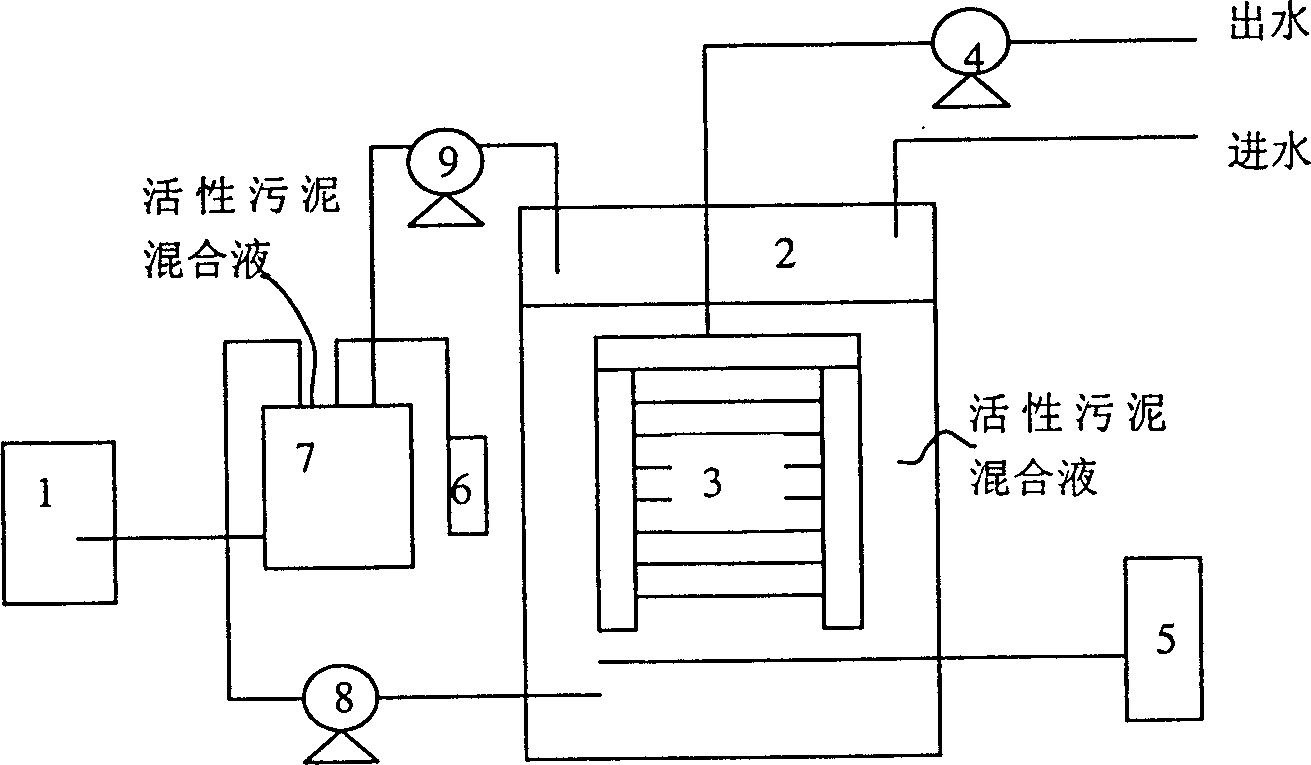

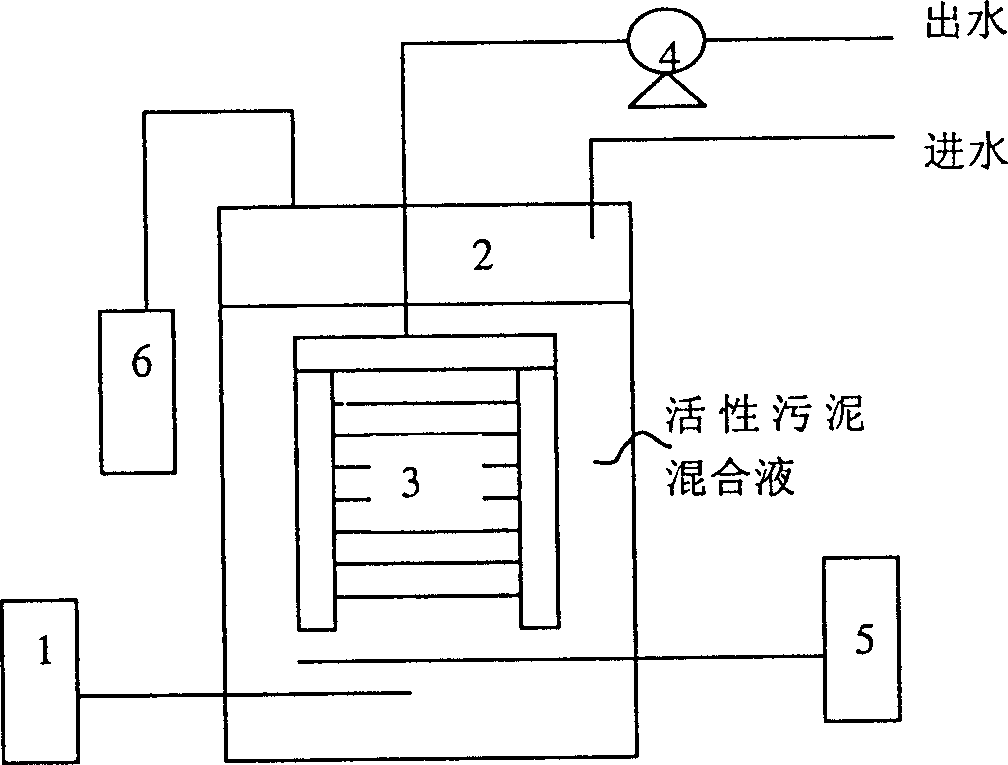

[0016] figure 1 Represent the membrane bioreactor device of the ozone regulation mixed liquid of embodiment one, this device is made up of ozone generator 1, biological reaction tank 2, membrane module 3, outlet pump 4, aerator 5, ozone tail gas absorption tank 6, ozone reaction Pool 7, sludge circulation pump 8, sludge circulation pump 9 and other components. Compared with the traditional membrane bioreactor, the device adds an ozone action system composed of an ozone generator and an ozone reaction tank.

[0017] The structure of this embodiment combines figure 1 The details are as follows:

[0018] In this example, two membrane bioreactors are used to investigate the change of membrane resistance over time. The greater the rate of increase in membrane resistance, the faster the development of membrane fouling. one for figure 1 Shown is the membrane bioreactor 1 of the ozone system, and the traditional membrane bioreactor 2 without the ozone system.

[0019] The sludge ...

Embodiment 2

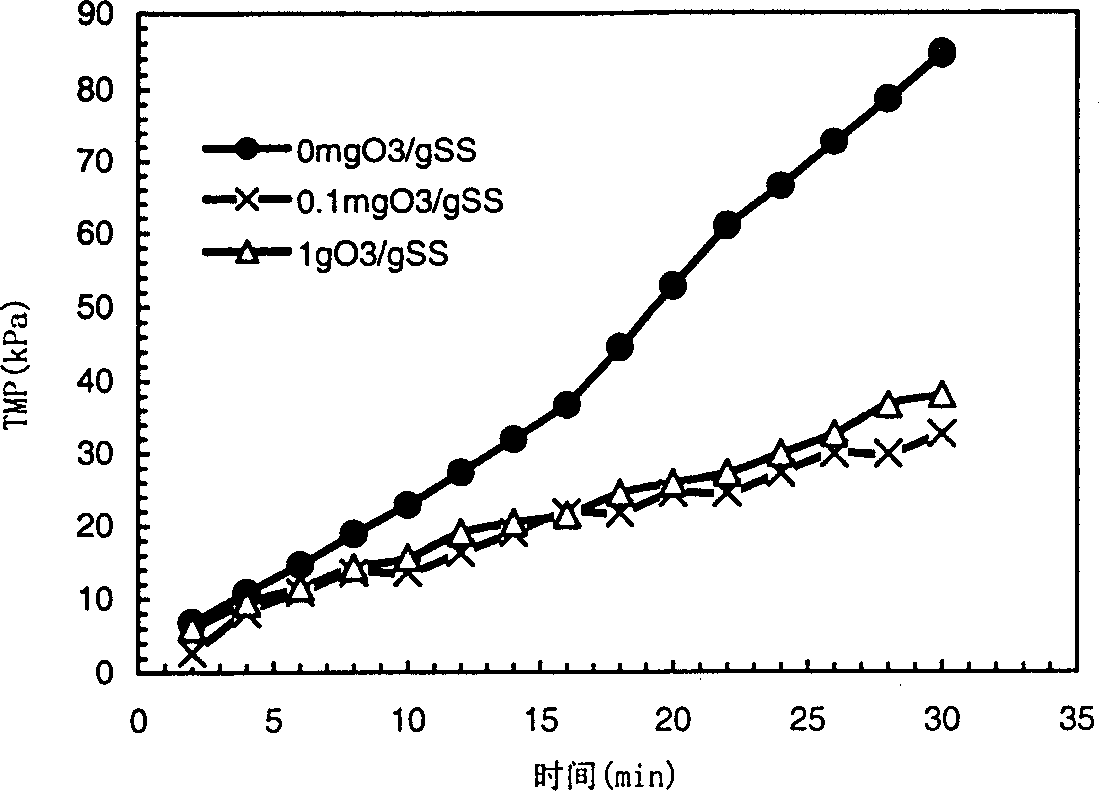

[0022] Ozone dosage (mg O 3 / g-SS)

[0023] It was found that the dosage of 100mg O 3 / g-SS, the rise rate of the membrane resistance of the two reactors is not much different. It shows that under this dosage, the effect of ozone on the mixed solution has almost no effect on the control of membrane fouling. But at 200, 300mg O 3 The increase rate of membrane resistance decreased by more than 35% and 40% respectively under the action of ozone at the dosage of / g-SS. It is proved that the effect of ozone on the mixed solution can control the development speed of membrane fouling in membrane bioreactor under this condition.

Embodiment 3

[0025]

[0026]It was found that when the sludge concentration was as low as 2g / L, the treatment of ozone aggravated the development of membrane fouling. However, under the normal operating conditions of the membrane bioreactor (sludge concentration above 4g / L), 120mg O 3 Ozone treatment with / g-SS dosage can play a role in slowing down membrane fouling. Even when the sludge concentration is as high as 20g / L, the resistance rise rate can be reduced by more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com