Filler composition, and preparing method and use thereof

A composition and chemical composition technology, applied in the direction of adding inorganic compounds, can solve the problems of limited filler filling, affecting papermaking process indicators and printing performance indicators, and deterioration of paper technical indicators, achieving stable performance, easy popularization and application, Effect without toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of Surfactant

[0039] Surfactant 1

[0040] In 13.0 gram of aluminum hydroxide, add 40 gram concentration and be the sulfuric acid solution of 60% by weight, stir at about 70 ℃ for 0.5 hour to carry out acidolysis, then add 12.5 gram of sodium silicate and 150 milliliters of water, stir at about 70 ℃ for 10 Minutes, cooled to crystallize, dried at about 100°C, and then pulverized to obtain Surfactant 1.

[0041] The chemical composition of Surfactant 1 measured by international general chemical full analysis method is: 13.1 parts by weight SiO 2 , 11.0 parts by weight Al 2 o 3 , 40.2 parts by weight SO 4 2- , 38.1 parts by weight of water of crystallization and 0.30 parts by weight of Fe 2 o 3 . where Fe 2 o 3 It is brought about by the impurities contained in the raw materials used.

[0042] Surfactant 2

[0043] Add 27 grams of concentration to 9.1 grams of aluminum hydroxide and be 60% by weight of sulfuric acid solution, stir at about 80°C f...

Embodiment 1

[0050] Mix raw materials 35 grams of bentonite (purchased from Sichuan Shuangliu Bentonite Powder Factory), 42 grams of talc (purchased from Liaoning Yingkou Nonmetal Company), 35 grams of natural calcium metasilicate (purchased from Jilin Lishu wollastonite company) with a plastic mixer , the trade name is Dadingshan brand), 7 grams of magnesium oxide (purchased from Liaoning Dashiqiao Non-Metal Company), pre-grinded into fine powder; 9.0 grams of surfactant 1 was pre-ground with a C×132 type superfine pulverizer Grinding into a fine-grained powder; using a plastic mixer to mix the above two fine-grained powders evenly, and further grinding to an average particle size of 5 microns.

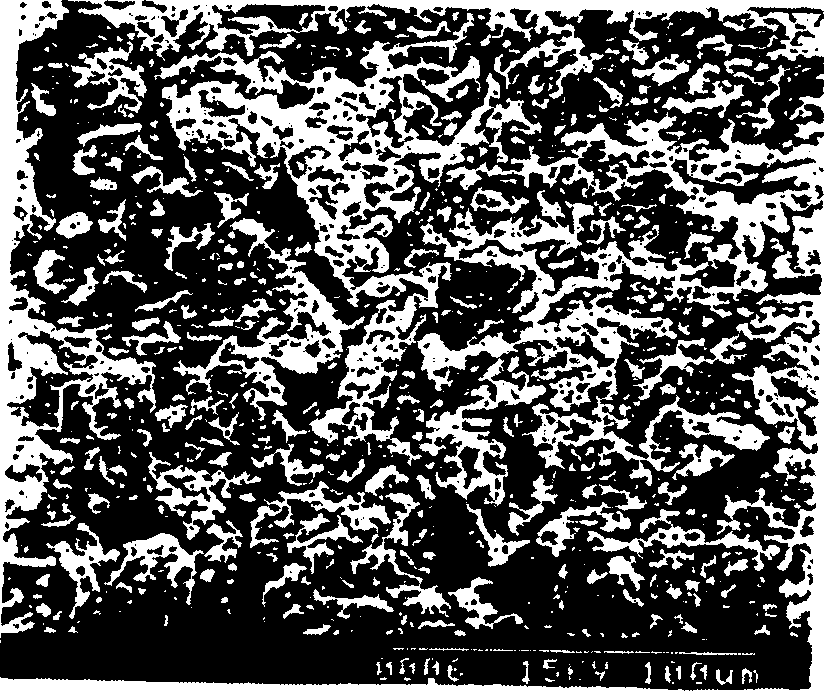

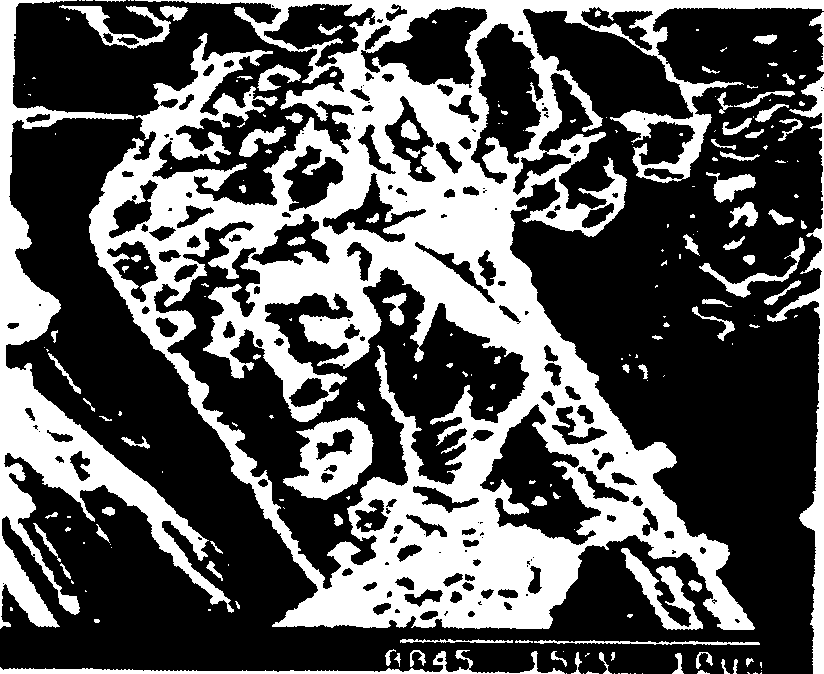

[0051] The obtained composition is a white powder with a whiteness of 90%. Measured by international general chemical full analysis method, the weight percentage of fibrous particles is 35%. Measured by S-530 electron microscope of Hitachi, Japan, the aspect ratio of fibrous particles is 11. Mea...

Embodiment 2

[0053] Mix 25 grams of bentonite (purchased from Sichuan Shuangliu Bentonite Powder Factory), 32 grams of talc (purchased from Liaoning Yingkou Non-metallic Company), 25 grams of natural calcium metasilicate (purchased from Jilin Lishu wollastonite Company) with a plastic mixer , the trade name is Dadingshan brand), 5 grams of magnesium oxide (purchased from Liaoning Dashiqiao Non-Metal Company), pre-grinded into fine powder; 6 grams of surfactant 2 pre- Grinding into a fine-grained powder; using a plastic mixer to mix the above two fine-grained powders evenly, and further grinding to an average particle size of 8 microns.

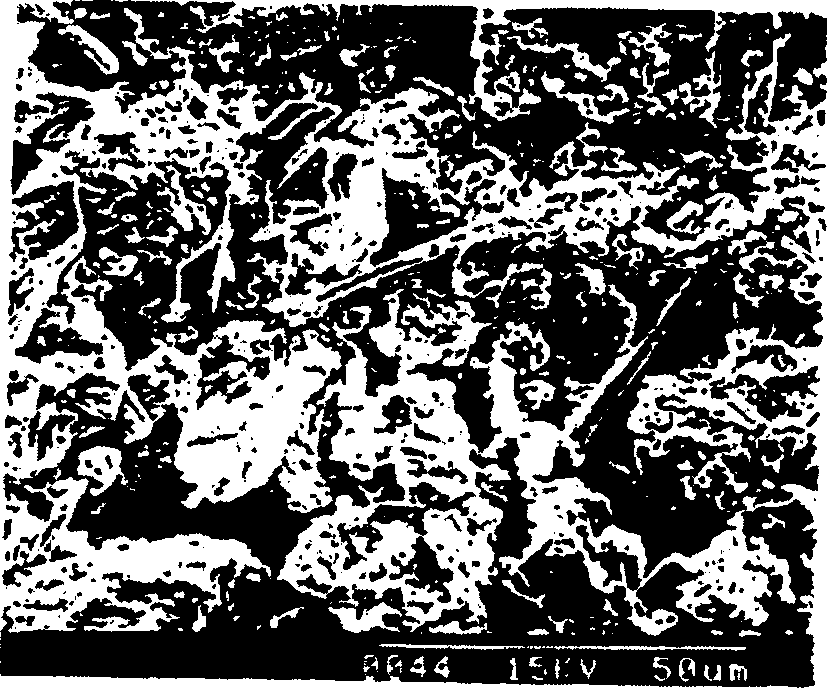

[0054] The obtained composition is a white powder with a whiteness of 88%. Measured by the international general chemical full analysis method, the weight percentage of fibrous particles is 15%, and measured by the S-530 electron microscope of Hitachi, Japan, the aspect ratio of the fibrous particles is 11. Measure the chemical composition of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com