Improved temperature control equipment of electric water heater

A technology of temperature control device and electric hot water, which is applied in the direction of temperature control without auxiliary power supply, fluid heater, beverage preparation device, etc., can solve the problems of high cost, complicated assembly, steam leakage, etc., and achieves convenient operation and simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

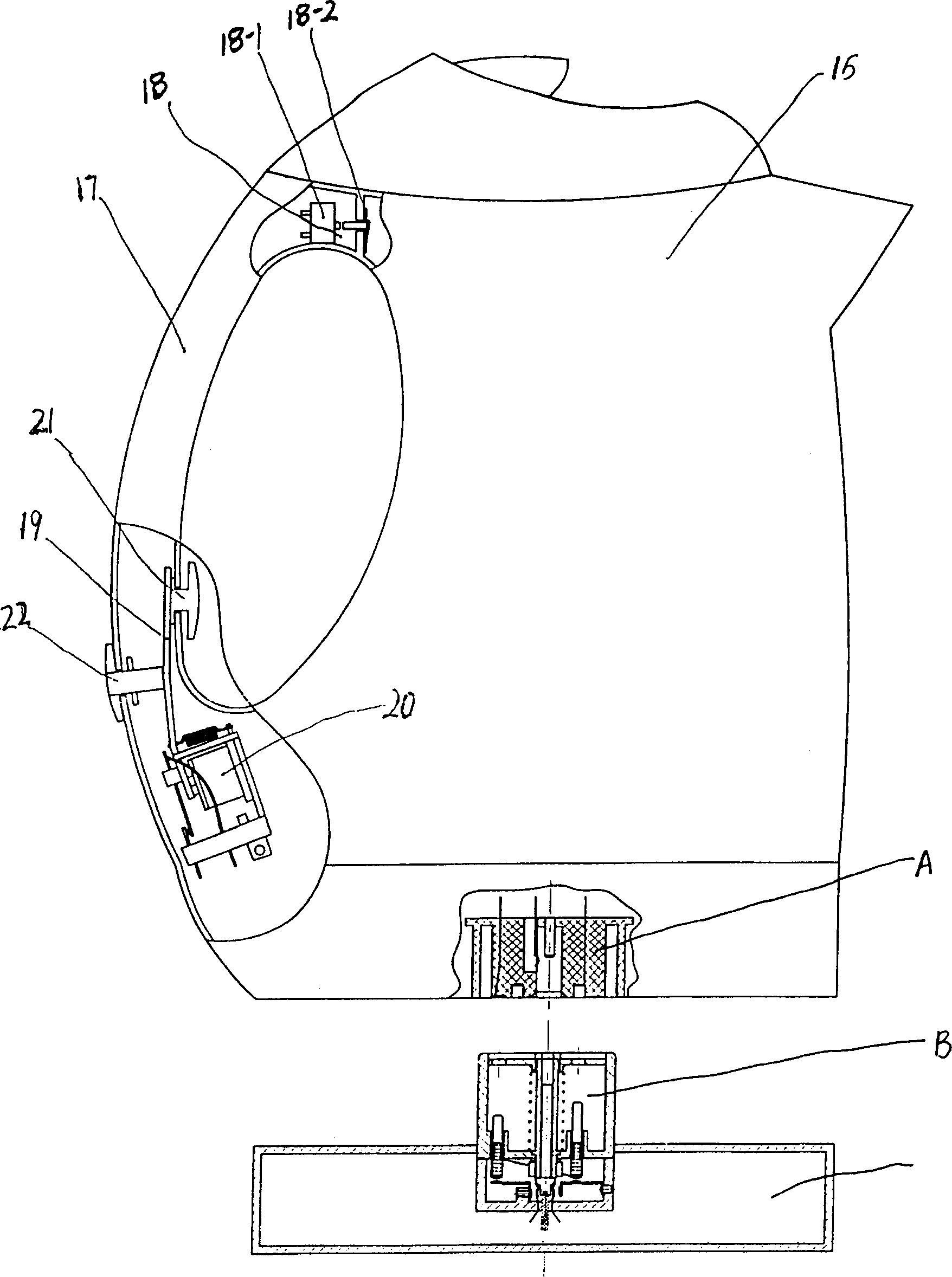

[0013] see figure 1 , the electric kettle includes a container 15, a base 16, a heater and a temperature control device installed on the container 15, and a safety electrical connector composed of a male plug A and a female socket B that are matched and plugged on the container 15 and the unit base 16. .

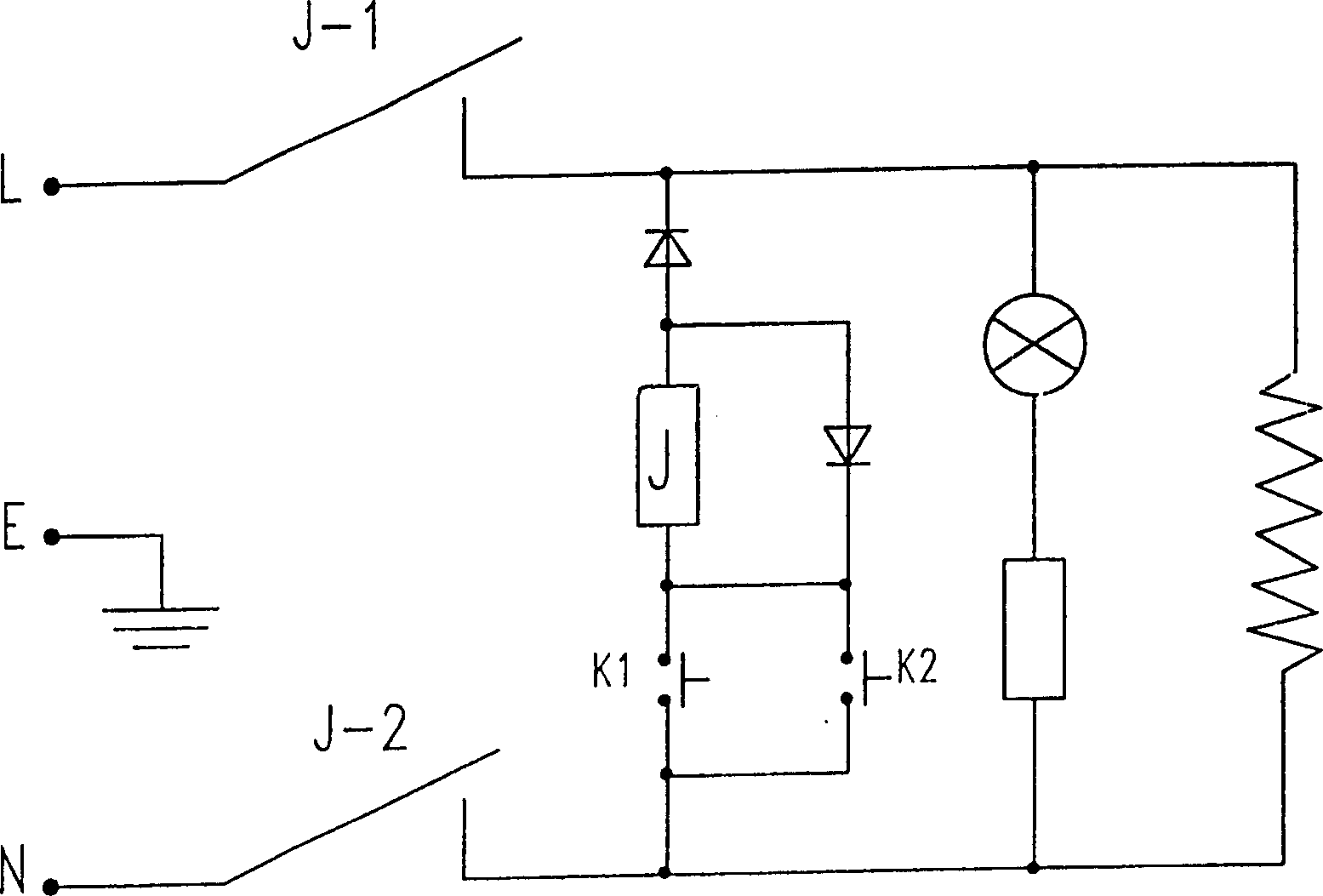

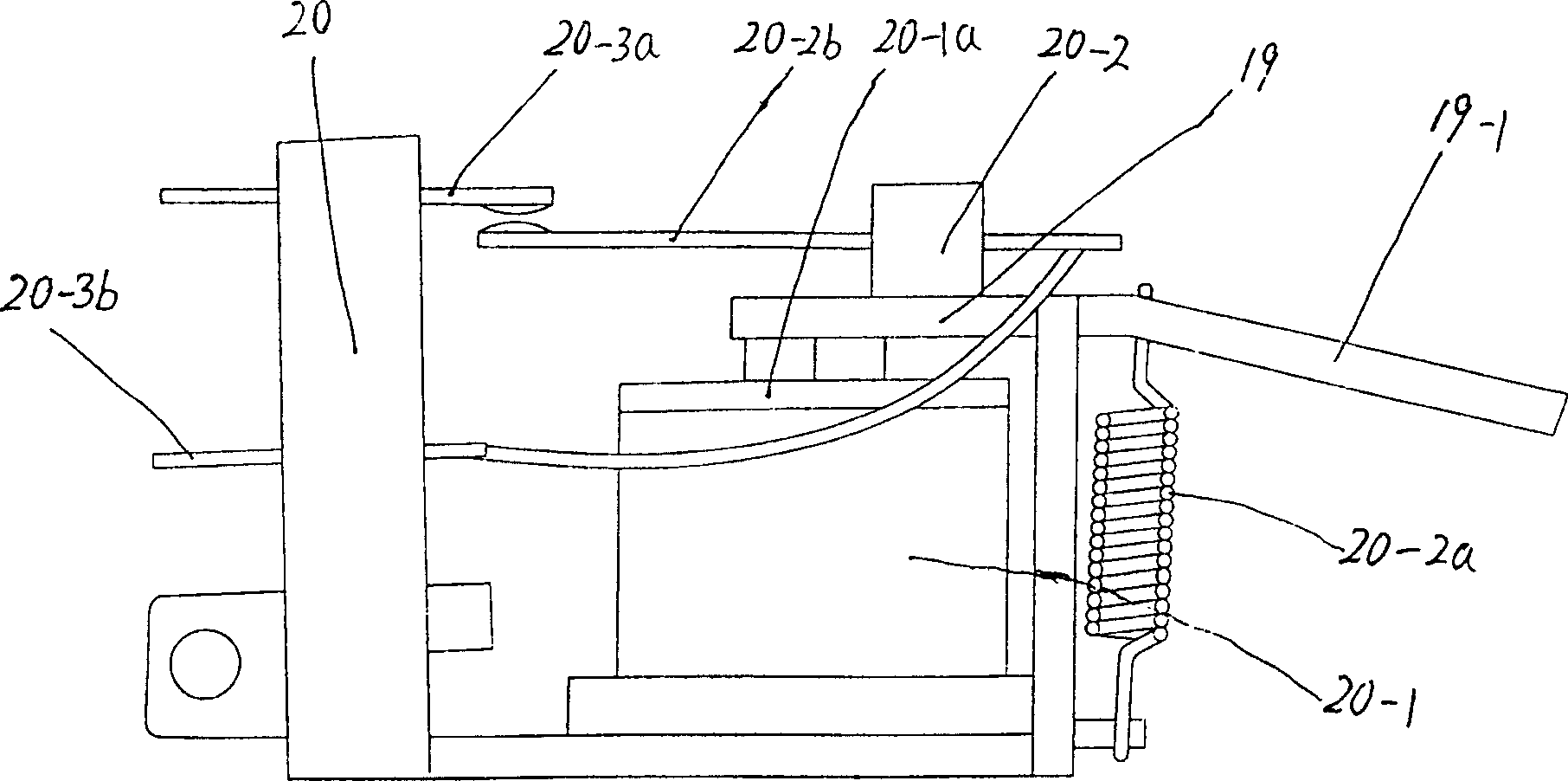

[0014] The temperature control device includes: a steam thermostat 18 installed on the inner wall of the container 15 and connected to the electrical connector, and a magnetic latching relay 20 connected in series between the steam thermostat 18 and the electrical connector. The steam thermostat 18 is made up of a normally open touch switch 18-1 and a thermosensitive bimetal 18-2. The magnetic latching relay is composed of a moving contact assembly 20-2, a static contact assembly and a magnetic circuit assembly 20-1; One end extends to the handle 17 of the container 15 to form a strip puller 19-1, the two sides of the puller 19-1 are respectively equipped with an opening b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com