Tea taste chewing gum without sugar and its preparation

A manufacturing method and technology of chewing gum, applied in chewing gum, tea extraction, pharmaceutical formula, etc., can solve the problems of increased process and equipment, increased manufacturing cost, and low utilization rate in the production of tea juice or tea extract, so as to reduce the process and improve Effect of quality and product cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

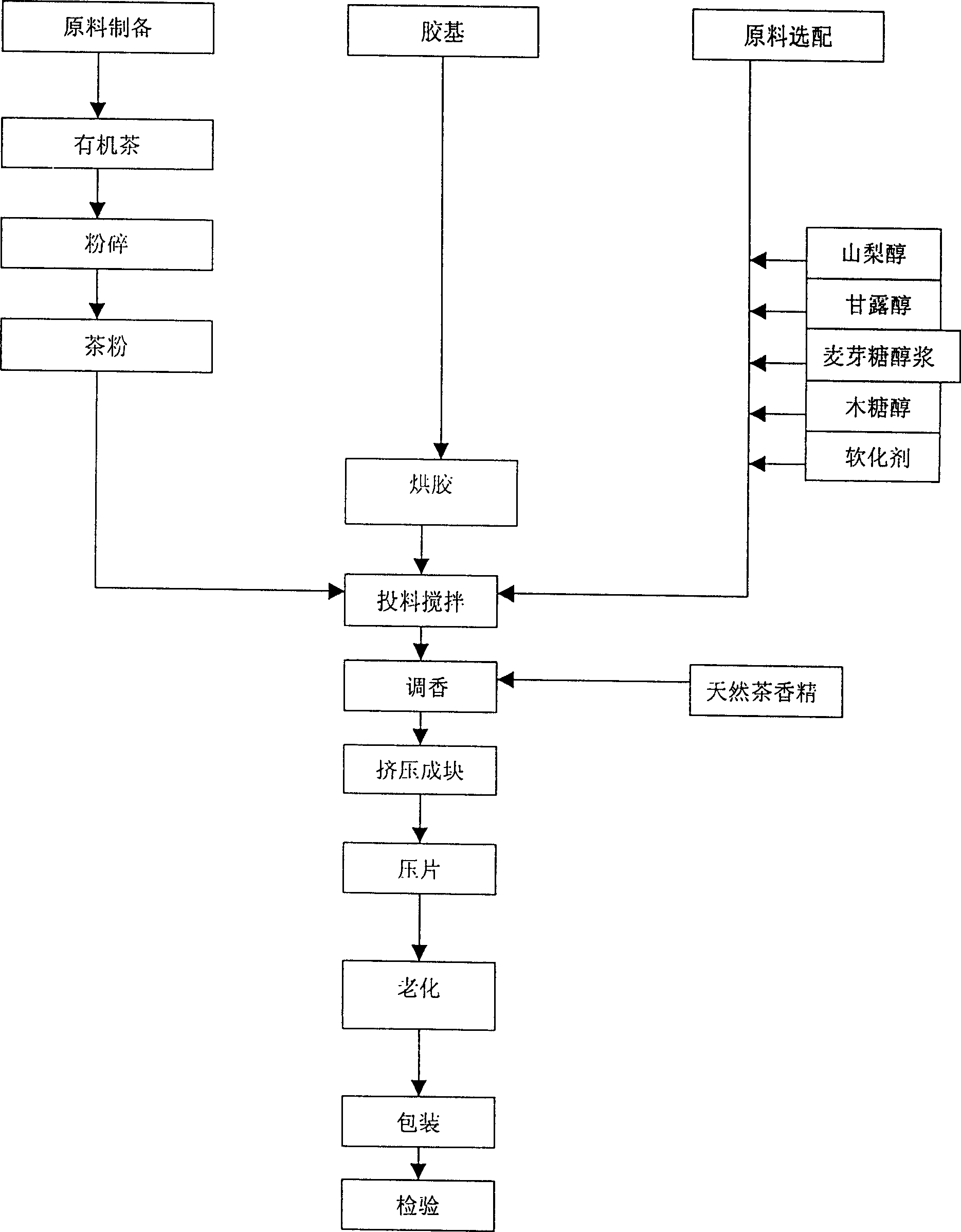

Method used

Image

Examples

Embodiment 1

[0025] The weight ratio of each raw material: gum base 20, 350 mesh tea powder 6, xylitol 10, sorbitol 40, mannitol 10, maltitol syrup 10, natural tea essence 1, softener 3.

[0026] The manufacture method of described tea-flavored sugar-free chewing gum is implemented in the following steps:

[0027] 1. Raw material prefabrication:

[0028] a. Glue drying: 50°C, 6 hours;

[0029] b. Making tea powder: dry the tea leaves to a water content of 3.5%, and then crush them to the specified requirements with an ultra-fine pulverizer;

[0030] 2. Stirring and flavoring: mix all the raw materials, stir evenly, and flavor as required;

[0031] 3. Finished product: Extrude the adjusted raw materials into blocks, press into tablets, and age. The aging temperature is 16°C, and the aging time is 22 hours;

[0032] 4. Packaging and inspection.

Embodiment 2

[0034] The weight ratio of each raw material: gum base 28, 450 mesh tea powder 2, xylitol 15, sorbitol 35, mannitol 5, maltitol pulp 10, natural tea essence 3, softener 2.

[0035] The manufacture method of described tea-flavored sugar-free chewing gum is implemented in the following steps:

[0036] 1. Raw material prefabrication:

[0037] a. Glue drying: 60°C, 4 hours;

[0038] b. Making tea powder: dry the tea leaves to a moisture content of 4.5%, and then use a ball mill to pulverize them to the specified requirements;

[0039] 2. Stirring and flavoring: mix all the raw materials, stir evenly, and flavor as required;

[0040] 3. Finished product: Extrude the adjusted raw materials into blocks, press into tablets, and age. The aging temperature is 22°C, and the aging time is 16 hours;

[0041] 4. Packaging and inspection.

Embodiment 3

[0043] Raw material weight ratio: gum base 20, 400 mesh tea powder 3, xylitol 11, sorbitol 35, mannitol 12, maltitol syrup 15, natural tea essence 1.5, softener 2.5.

[0044] The manufacture method of described tea-flavored sugar-free chewing gum is implemented in the following steps:

[0045] 1. Raw material prefabrication:

[0046] a. Glue drying: 55°C, 5 hours;

[0047] b. Making tea powder: dry the tea leaves to a water content of 4.%, and then crush them to the specified requirements with an airflow mill, and the working temperature is lower than 80°C;

[0048] 2. Stirring and flavoring: mix all the raw materials, stir evenly, and flavor as required;

[0049] 3. Finished product: Extrude the adjusted raw materials into blocks, press into tablets, and age. The aging temperature is 20°C, and the aging time is 18 hours;

[0050] 4. Packaging and inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com