Powdered coal burner and burning device using said powdered coal burner

A burner, pulverized coal technology, used in burners, burners, combustion methods, etc. for burning powder fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The pulverized coal burner and the combustion device using the pulverized coal burner of the present invention will be described below with reference to the illustrated embodiments. However, the present invention is not limited to these Examples.

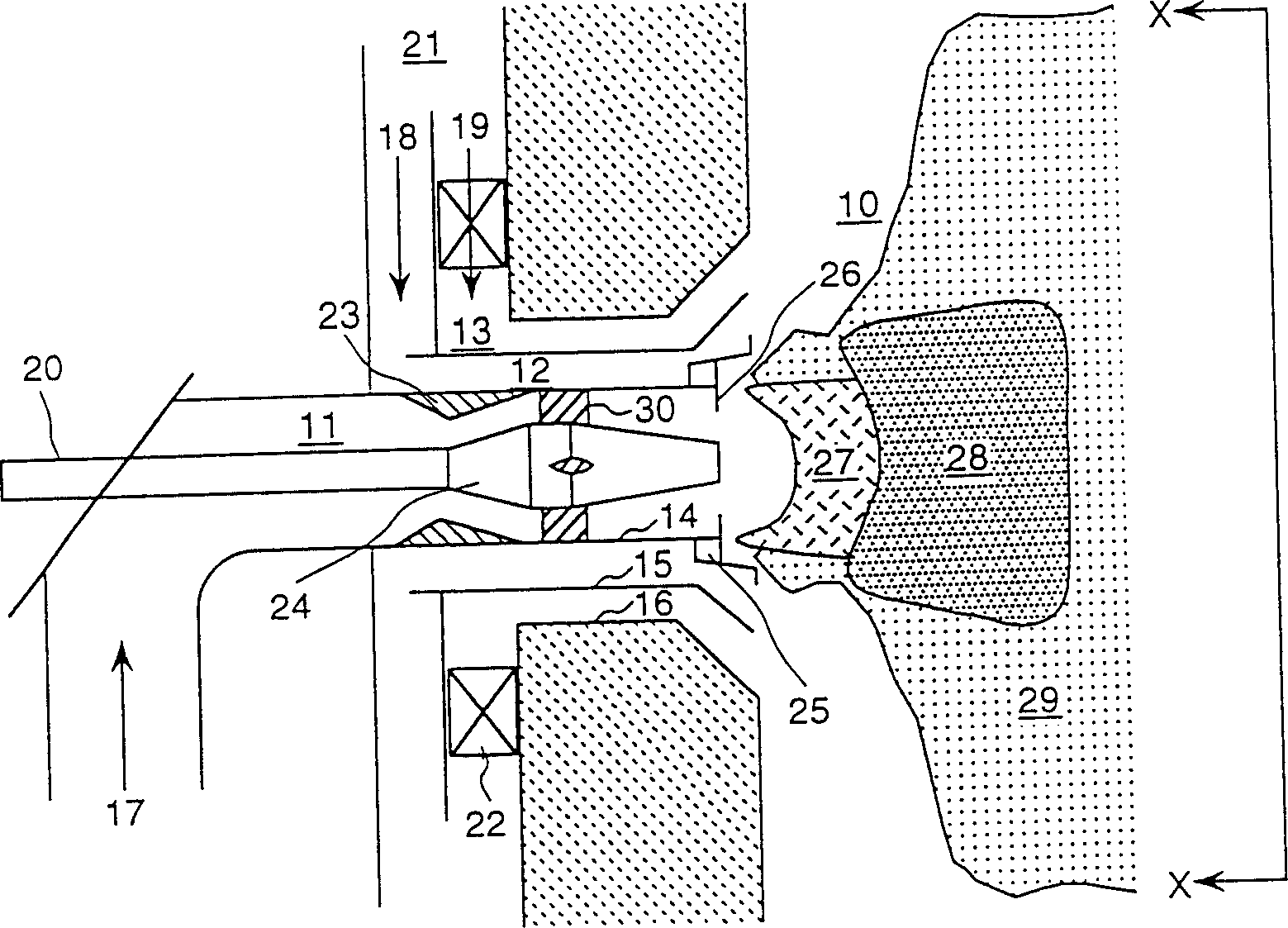

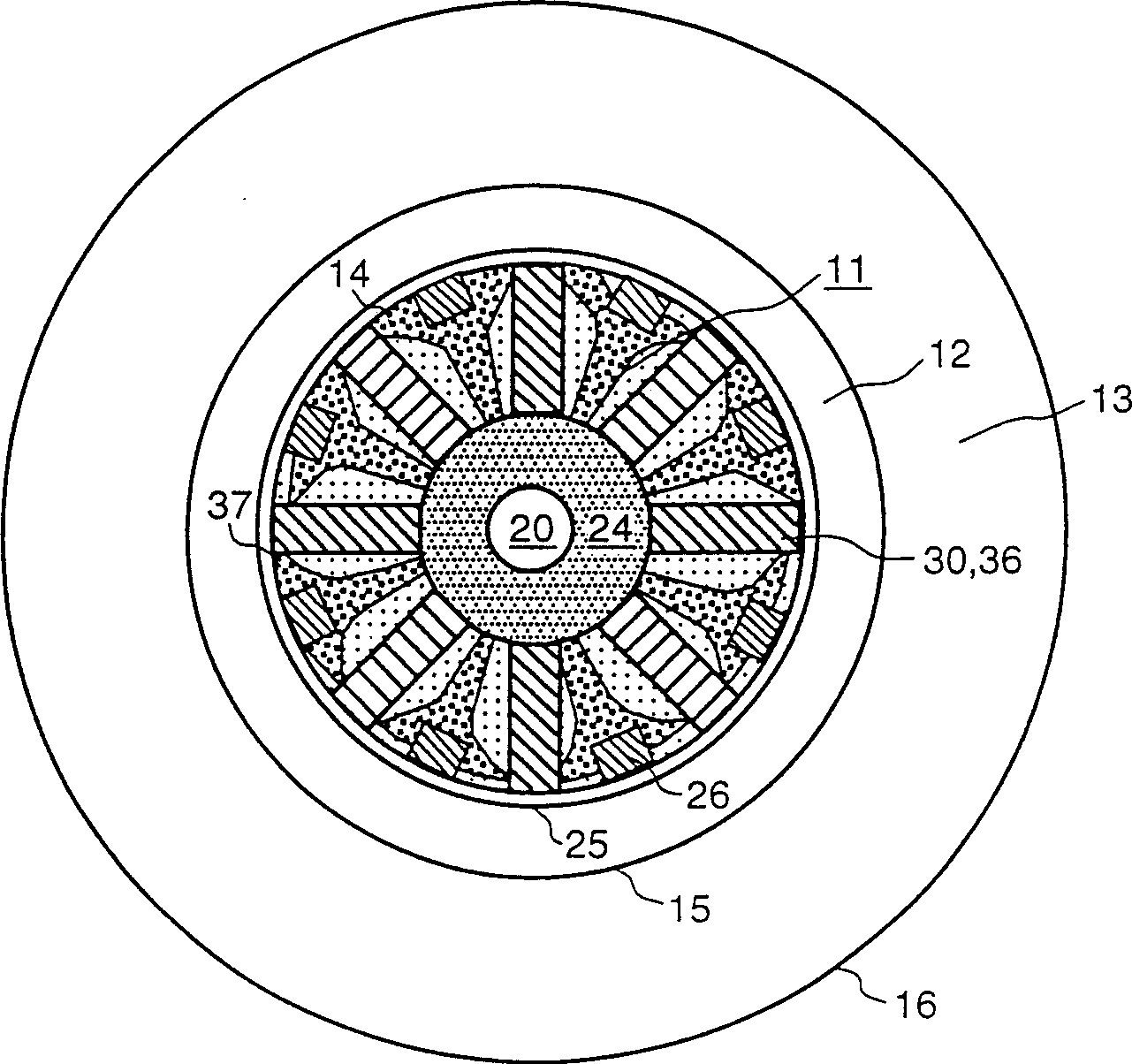

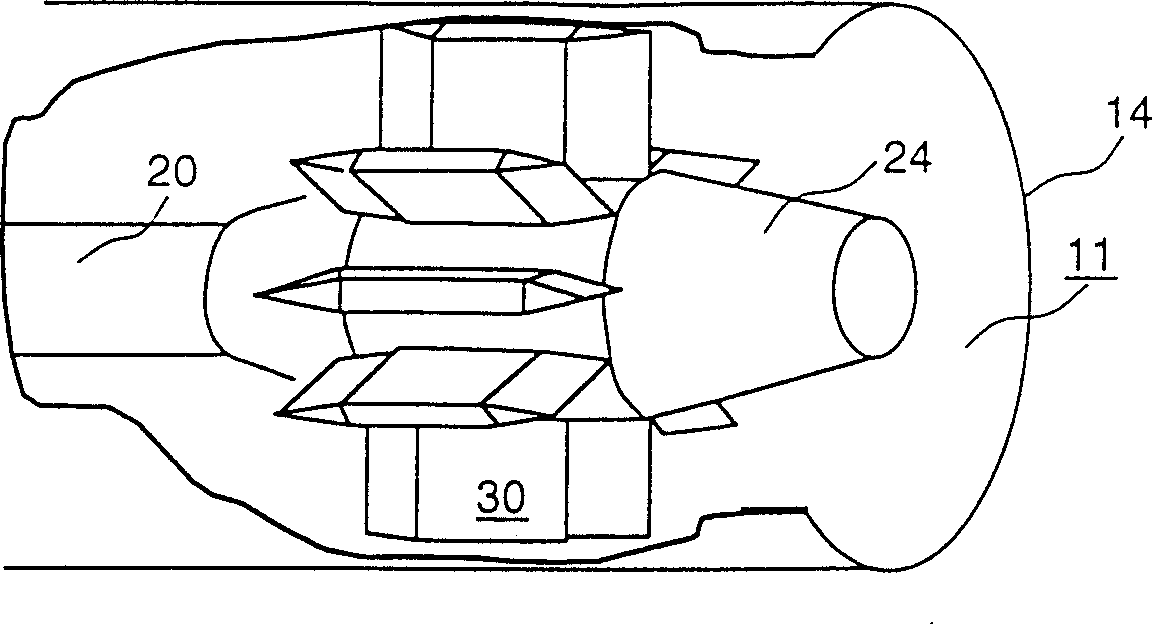

[0057] figure 1 and 2 shows the pulverized coal burner of the first embodiment of the present invention, wherein figure 1 is a side cross-sectional view of a pulverized coal burner with a centerline, figure 2 is from the centerline direction and from figure 1 The front view of the pulverized coal burner viewed in the X direction of the middle arrow, in these figures, the symbol 30 is a plate-shaped part, and other components are the same as Figure 13 and 14 The reference numerals used in the prior art examples shown are substantially the same.

[0058] As mentioned above, the formation of reducing atmosphere 28 in the flame is very important for eliminating NO X is important, additionally, in order to reduce NO X ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com