Method of preparing lanthanum lead zirconium titanate transparent photoelectric ceramic

A technology for optoelectronic ceramics and lanthanum zirconate titanate, which is applied in the field of low-cost preparation of lanthanum zirconate titanate and lead transparent ceramics, can solve problems such as high manufacturing cost, and achieve the effects of low equipment requirements, simple process flow and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

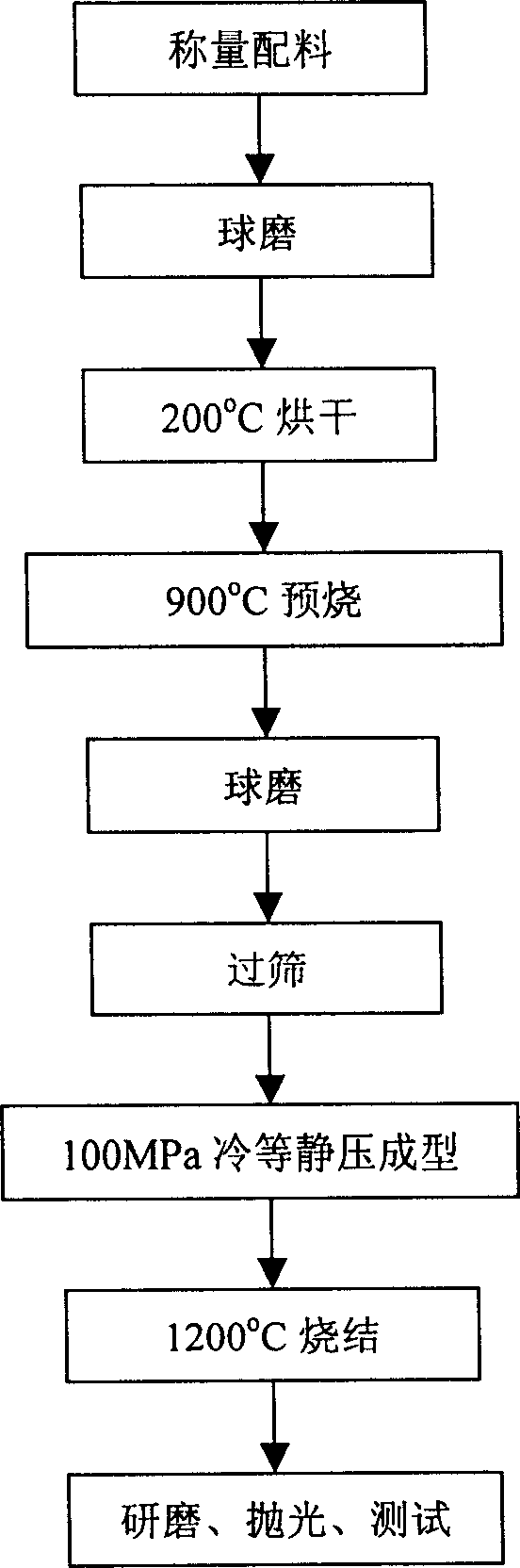

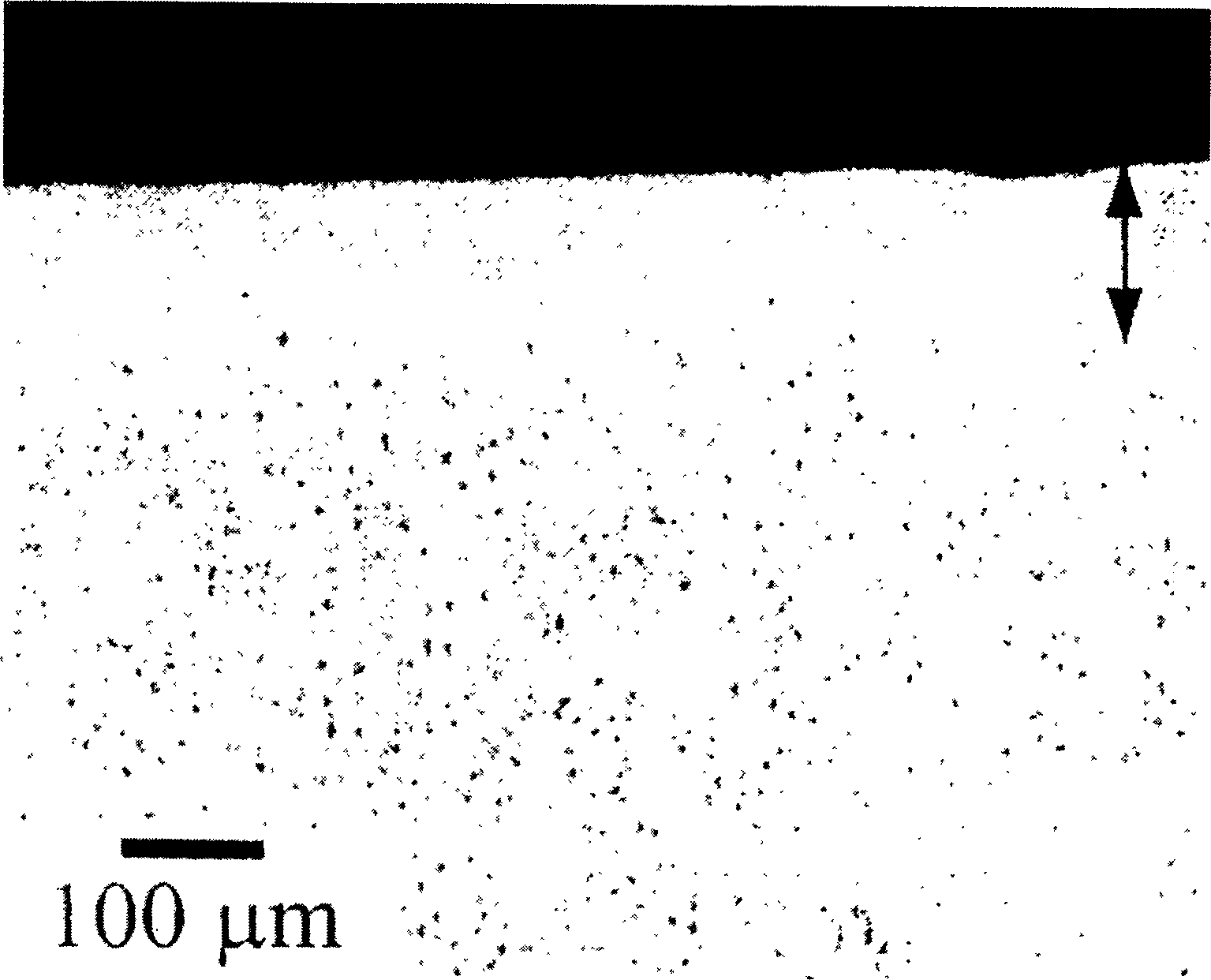

[0020] Embodiment 1, earlier use the plumbous oxide of analysis pure (99.9%) level, lanthanum trioxide, zirconium dioxide and titanium dioxide reagent, be (Pb 1-x La x )[(Ti 1-y Zr y ) 1-x / 4 V Bx / 4 ] carry out weighing batching, promptly add-4wt% excessive lead oxide during batching, will add the batching of excessive lead oxide and put into ball mill tank and add the dehydrated alcohol ball mill of 1: 1 5 hours, after drying at 200 ℃, Pre-fired at 900°C for 2 hours, ball milled for 24 hours, dried, sieved, and cold isostatic pressed at 100MPa to make raw culture products with a thickness of 0.3mm and a diameter of 10mm. 3 Sintering at 1200°C for 8 hours under atmosphere protection conditions. After natural cooling, the section of the raw culture product is ground and polished with 1 micron alumina abrasive.

Embodiment 2

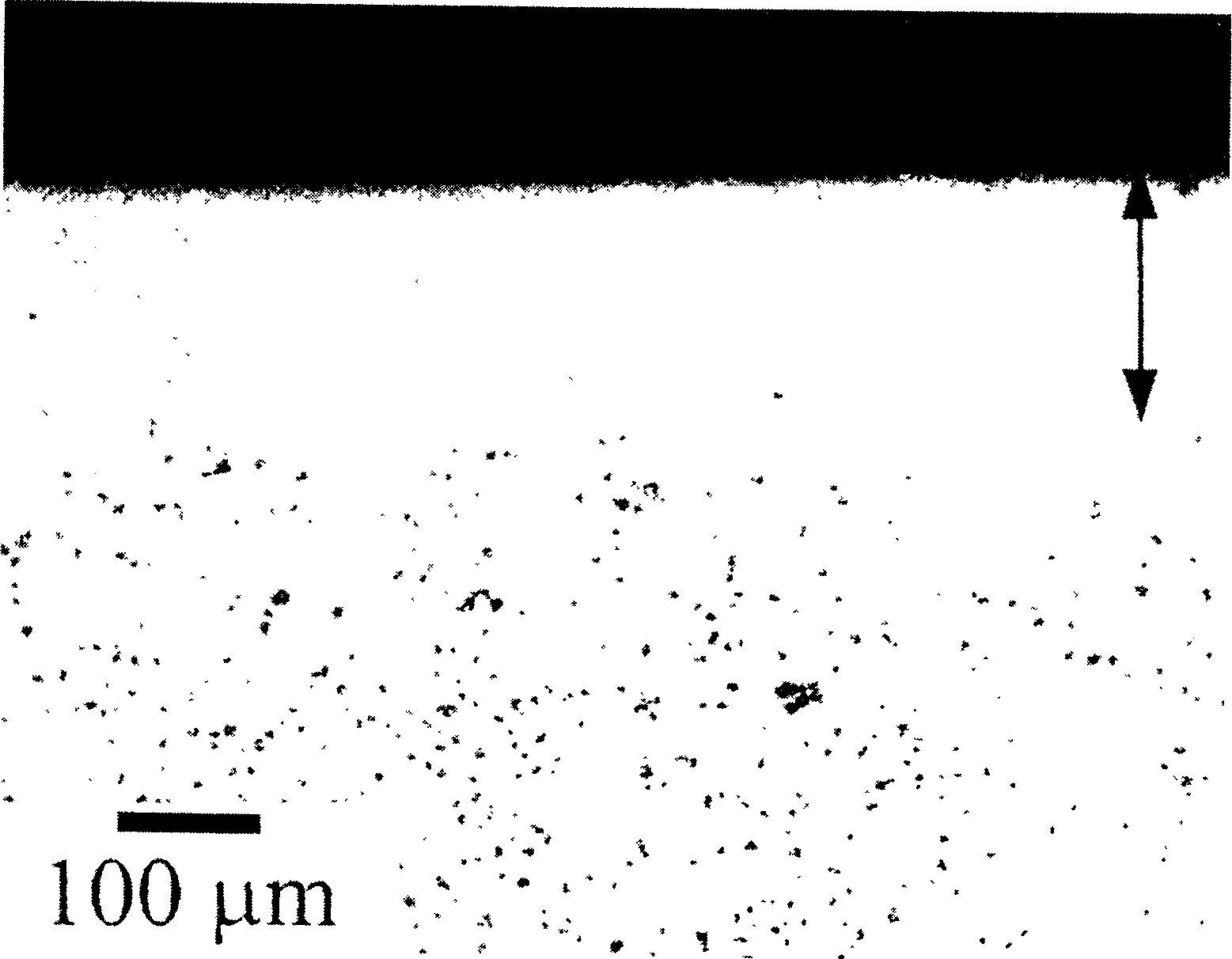

[0021] Embodiment 2, earlier use the plumbous oxide of analysis pure (99.9%) grade, lanthanum trioxide, zirconium dioxide and titanium dioxide reagent, be (Pb 1-x La x )[(Ti 1-y Zr y ) 1-x / 4 V Bx / 4 ] carry out weighing batching, promptly add the excess lead oxide of 0wt% during batching, will add the batching of excessive lead oxide and put into the ball mill jar and add the dehydrated alcohol ball mill of 1: 1 for 5 hours, after drying at 200 ℃, in Pre-fired at 900°C for 2 hours, ball milled for 24 hours, dried, sieved, and cold isostatic pressed at 100MPa to make raw culture products with a thickness of 0.3mm and a diameter of 10mm. 3 Sintering at 1200°C for 8 hours under atmosphere protection conditions. After natural cooling, the section of the raw culture product is ground and polished with 1 micron alumina abrasive.

Embodiment 3

[0022] Embodiment 3, earlier use the plumbous oxide of analysis pure (99.9%) grade, lanthanum trioxide, zirconium dioxide and titanium dioxide reagent, be (Pb 1-x La x )[(Ti 1-y Zr y ) 1-x / 4 V Bx / 4 ] carry out weighing batching, promptly add the excess lead oxide of 4wt% during batching, will add the batching of excessive lead oxide and put into ball mill jar and add the dehydrated alcohol ball mill of 1: 1, after drying at 200 ℃, in Pre-fired at 900°C for 2 hours, ball milled for 24 hours, dried, sieved, and cold isostatic pressed at 100MPa to make raw culture products with a thickness of 0.3mm and a diameter of 10mm. 3 Sintering at 1200°C for 8 hours under atmosphere protection conditions. After natural cooling, the section of the raw culture product is ground and polished with 1 micron alumina abrasive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com