Lubricant composition

A technology of lubricating oil composition and compound, applied in the direction of lubricating composition, 6/16 group organic compounds without C-metal bond, additives, etc., to achieve excellent anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

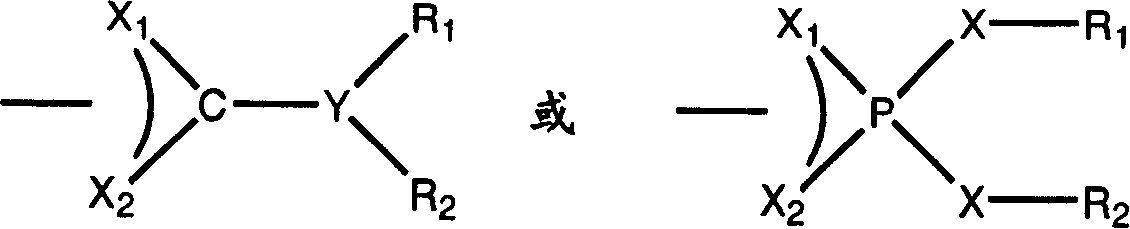

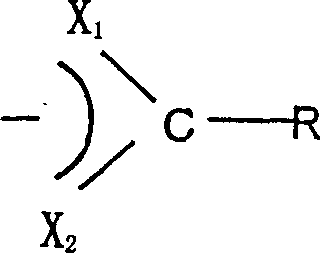

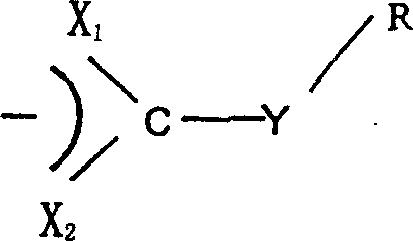

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1, preparation Mo 3 S 7 (Henki 2 dtc) 2 (S 2 )

[0069] Methanol (50 mL), dioctylamine (0.66 mL, 2.2 mmol) and carbon disulfide (0.13 mL, 2.2 mmol) were mixed and stirred in a 250 mL round bottom flask under nitrogen atmosphere for 2 hours. join (NH 4 ) 2 Mo 3 S 13 (750 mg, 1 mmol) and the mixture was heated to reflux overnight. The red solid in the mixture was removed by heating and methanol was decanted from the red solid. The solid was washed with methanol, dried, dissolved in toluene and filtered. Toluene was removed by vacuum distillation to obtain a dark red transparent solid product whose elemental analysis corresponds to that of Mo 3 S 7 (Henki 2 dtc) 2 (S 2 ).

Embodiment 2

[0070] Embodiment 2 prepares Mo 3 S 7 (coco-based 2 dtc) 2 (S 2 ):

[0071] Methanol (50 mL), dicocoamine (1.00 g, 2.2 mmol) and carbon disulfide (0.13 mL, 2.2 mmol) were combined and stirred in a 250 mL round bottom flask under nitrogen atmosphere for 2 hours. To the solution was added (NH 4 ) 2 Mo 3 S 13 (750 mg, 1 mmol). The mixture was heated to reflux overnight. The solution was removed with heat and the methanol was decanted from the red solid. The solid was washed with methanol and dried. The product was dissolved in toluene and filtered. Toluene was distilled off in vacuo to obtain a dark red transparent solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com