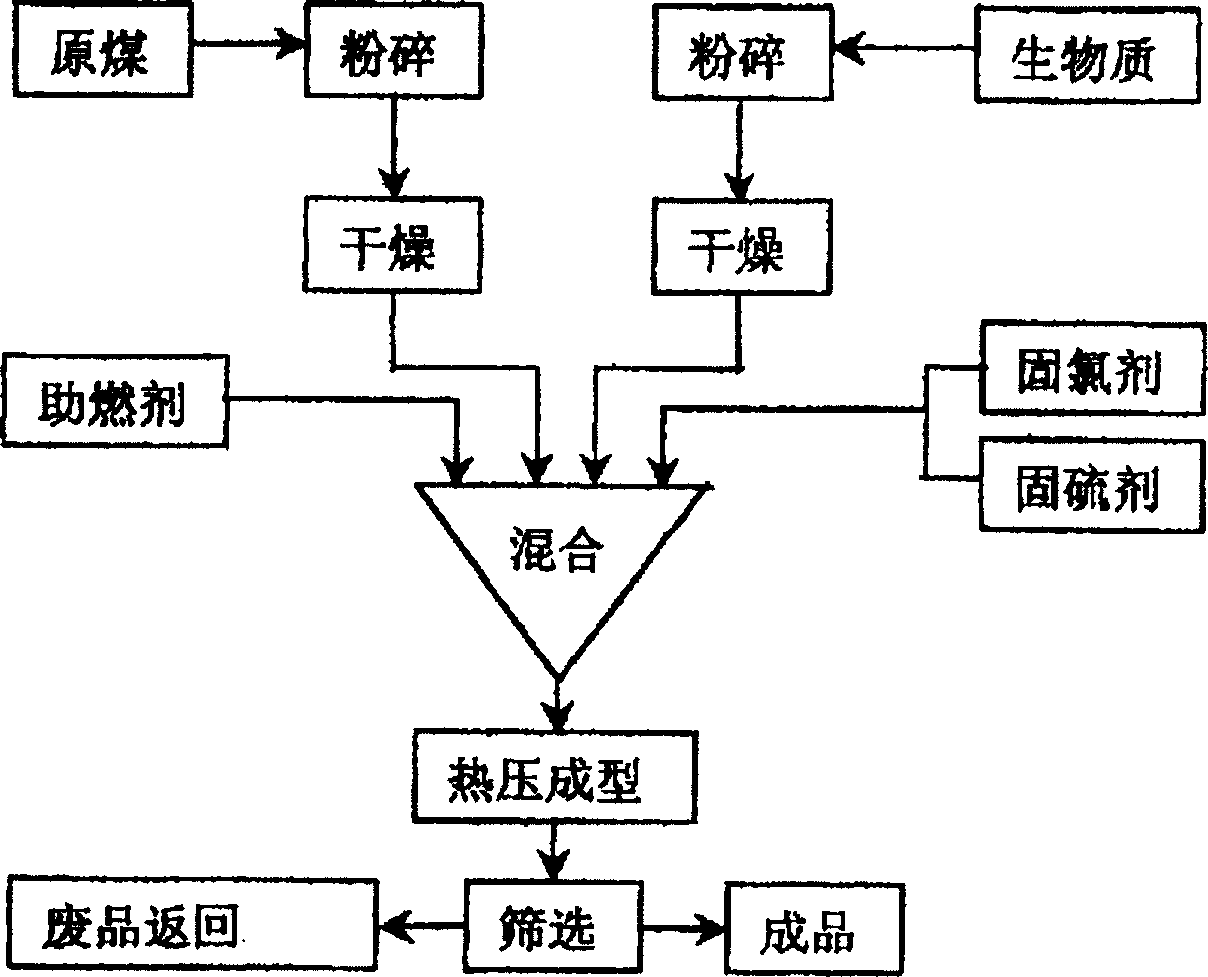

Process for preparing composite biomass briquettes

A composite briquette and production process technology, which is applied in the field of biomass composite briquette production technology, can solve problems such as poor strength, difficult ignition, black smoke, etc., and achieve the effects of low dust discharge, low cost and high sulfur fixation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Proportion: 40% biomass + 60% lignite, adding CaO (Ca / S=1.0), Na 2 CO 3 (Na / Cl=1.0) and 0.1% Fe of the total fuel mass 2 o 3 ;

[0024] Molding pressure: 50Mpa; hot pressing temperature 140°C

[0025] Briquette size: diameter 35mm, length 30mm;

[0026] Combustion temperature: 850°C

[0027] 2) Implementation results

[0028] Briquette compressive strength > 20Mpa

[0029] Ignition point: 343°C, calorific value of composite briquette 20198.10Kj / kg;

[0030] Burnout rate = 96%, small thermal expansion during combustion, no automatic fragmentation during combustion, very little fly ash, and no black smoke;

[0031] The sulfur fixation rate is 76%, the chlorine fixation rate is 70%, and the nitrogen oxide emission concentration is less than 100mg.m -3 ;

Embodiment 2

[0033] 1) Implementation conditions

[0034] The characteristics of biomass fuel and lignite are the same as Example 1;

[0035] Proportion: 40% biomass + 60% lignite, reinforced sulfur agent CaO (Ca / S=2.0), 0.15% LSCF-8291, Na 2 CO 3 (Na / Cl=2.0);

[0036] Forming pressure: 50Mpa; hot pressing temperature 150°C

[0037] Briquette size: diameter 35mm, length 30mm;

[0038] Combustion temperature: 850°C;

[0039] 2) Implementation results

[0040] Briquette compressive strength> 20Mpa;

[0041] Ignition point: 332°C, calorific value of composite briquette 20250.06kJ / kg;

[0042] Burnout rate > 95%, ash is not broken, dust emission concentration -3 ;

[0043] Sulfur fixation rate = 87%, chlorine fixation rate 81%, nitrogen oxide emission -3 ;

Embodiment 3

[0045] 1) Implementation conditions

[0046] Proportion: 60% biomass + 40% lignite, adding composite sulfur fixative (CaO), carbide slag, iron series fossils, Ca / S≥1.5), Na 2 CO 3 (Na / Cl=2.0), 0.2% mixed combustion aid (Fe 2 o 3 ):LSCF-8291=1:1)

[0047] Molding pressure: 50Mpa; Molding temperature 150°C

[0048] Briquette size: diameter 35mm, length 30mm;

[0049] Combustion temperature: 850°C;

[0050] 2) Implementation results

[0051] Briquette compressive strength ≥ 22Mpa;

[0052] Ignition point = 320°C, calorific value 18811.87kJ / kg;

[0053] Burnout rate = 97%, dust emission concentration -3 , no obvious black smoke generation; sulfur fixation rate = 92%, chlorine fixation rate = 90%, nitrogen oxide emission does not exceed 90mg.m -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com