Micropowder functional material production method

A technology of functional materials and manufacturing methods, applied in the direction of fibrous fillers, chemical instruments and methods, botany equipment and methods, etc., can solve problems such as large time burden, obstacles to rationalization of manufacturing processes, and high product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

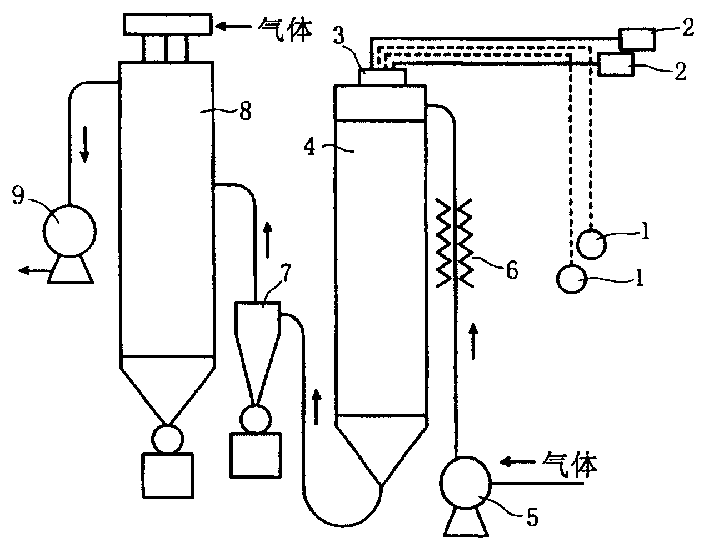

[0071] figure 1 It is an explanatory diagram showing the spray drying apparatus used in the method of the present invention.

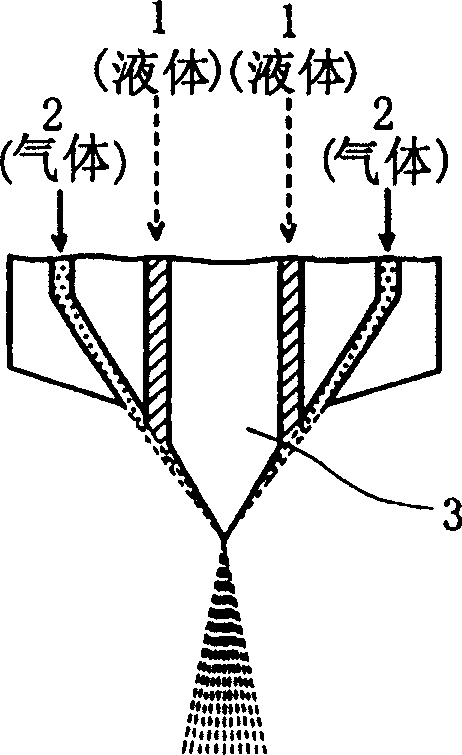

[0072] figure 2 yes figure 1 An enlarged illustration of the four-fluid nozzle in the setup.

[0073] exist figure 1 and figure 2 Among them, 1 is the liquid supply system, 2 is the gas supply system, 3 is the nozzle (four-fluid nozzle), 4 is the device body (tank), 5 is the blower, 6 is the heater, 7 is the cyclone, 8 is the bag filter, 9 is exhaust fan.

[0074] The liquid supply system 1 and the gas supply system 2 are respectively composed of two flow paths, such as figure 2 As shown, spray at the front end of nozzle 3. Recovery (collection) of the product may be performed using both the cyclone 7 and the bag filter 8, or may be performed using either one of them.

[0075] 10 parts by weight of catechin with a purity of 30% by weight was added to 100 parts by weight of a hydrocolloid solution of colloidal silicon dioxide having a solid c...

Embodiment 1 Embodiment 2 Embodiment 3

[0087] Time (min) 5 5 60 120 180

[0088] Inlet temperature (℃) 200 250 250 250 250

[0089] Exhaust temperature (℃) 85 107 99 102 111

[0090] Tower inner pressure (kpa) 0.4 0.5 0.8 0.7 0.6

[0091] Supply air volume (m 3 / min) 1.1 0.85 0.85 0.85 0.87

[0092] 1 gas

[0093] Pressure (MPa) 0.69 0.69 0.69 0.69 0.68

[0094] Flow (NL / min) 80 80 80 80 80

[0095] 2 gas

[0096] Pressure (MPa) 0.69 0.69 0.69 0.69 0.69

[0097] Flow (NL / min) 80 80 80 80 80

[0098] 1 liquid

[0099] Flow (ml / min) 20 20 20 20 10

[0100] 2 liquids

[0101] Flow (ml / min) 20 20 20 20 10

[0102] BF cylinder internal pressure (kPa) 0.3 0.4 1 0.7 0.5

[0103] Recovery (g) 46.8 32.6 94.6 877 722

[0104] Median diameter (μm) 5.614 6.075 5.808 6.412 5.949

[0105] Mode diameter (μm) 6.512 6.514 6.512 7.527 6.512

[0106] Average particle diameter (μm) 5.598 6.298 5.873 6.624 6.217

[0107] Standard Deviation 0.293 0.324 0.302 0.329 0.321

[0108] 25% diameter (μm) 3.680 3.914...

Embodiment 4~5

[0112] 40 parts by weight of an aqueous solution having a concentration of 25% by weight of polyamino acid (polylysine) was added to 100 parts by weight of a colloidal silica hydrocolloid solution having a solid content of 40% by weight, and mixed to prepare an aqueous slurry. This aqueous slurry was spray-dried under the conditions of Example 1 using a research spray drying apparatus "Micromist Driya MDL-050-Type B" of Fujisaki Electric Co., Ltd. Conditions and results are shown in Table 2.

[0113] Table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com