Method for preparing alkyl end capping polyether using alkyl halide as end capping reagent

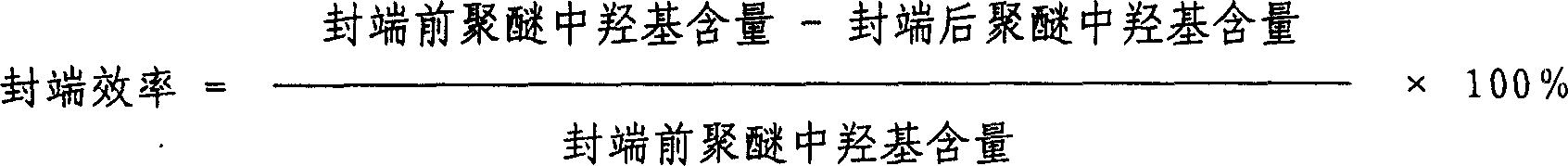

A technology of alkyl end-capping and haloalkane, which is applied in the field of preparation of alkyl-termination polyether with haloalkane as the end-capping agent, which can solve the problems of increasing the end-capping agent, achieve the effect of reducing the usage amount and improving the end-capping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 500 ml four-necked flask, add 200 g of butanol polyether (EO / PO=50 / 50, random, hydroxyl value 36), 13.0 g of solid potassium hydroxide, and 4.0 g of anhydrous sodium sulfite (antioxidant). It was replaced with nitrogen 4 times with stirring, and then reacted at a temperature of 90 to 100° C. for 1 hour. 3.3 grams of calcium oxide powder was added, vigorously stirred, and 11.7 grams of methylene chloride was added dropwise, and the reaction was continued at 120-130° C. for 4 hours after the dropwise addition. Add 100 ml of water to wash the reaction product, stir at 90 ° C for 1 hour, maintain 80 ~ 90 ° C to make the reactant stand for stratification, remove the water phase, vacuum dehydration, filter to remove solid impurities, and obtain the end-capped polyether product.

Embodiment 2

[0035] In a 500 ml four-necked flask, add 200 grams of butanol polyether (EO / PO=50 / 50, random, hydroxyl value 36), 14.0 grams of solid potassium hydroxide, 4.0 grams of anhydrous sodium sulfite, and 9.3 grams of calcium oxide, Stir vigorously. It was replaced with nitrogen four times under stirring, and the reaction was carried out at 90 to 100° C. for 1 hour. 11.7 g of monochloromethane was added dropwise, and the reaction was continued at 110-120° C. for 4 hours after the dropwise addition was completed. Add 100 ml of water, stir at 90°C for 1 hour, maintain 80-90°C to allow the reactants to stand for stratification, remove the aqueous phase, dehydrate in vacuo, and filter to remove solid impurities to obtain the end-capped polyether product

Embodiment 3

[0037] In a 500 ml four-necked flask, add 200 g of polyethylene glycol (hydroxyl value 78), 30.4 g of solid potassium hydroxide, 4.0 g of anhydrous sodium sulfite, 12.2 g of calcium oxide, and 80 ml of xylene. A stirring reaction was performed at a temperature of 90 to 100° C. for 1 hour. 27.4 g of monochloromethane was added dropwise, and the reaction was continued at 110-120° C. for 4 hours after the dropwise addition was completed. Add 100 ml of water, stir at 90°C for 1 hour, maintain 80-90°C to allow the reactant to stand for stratification, remove the aqueous phase, remove the solvent in vacuo, and filter to remove solid impurities to obtain the end-capped polyether product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com