Railway sleeper and its preparing method

A technology for sleepers and railways, applied in tracks, roads, ballast layers, etc., can solve problems such as environmental protection and natural ecological balance damage, and achieve the effect of small thermal expansion and contraction coefficient, stable foundation, and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

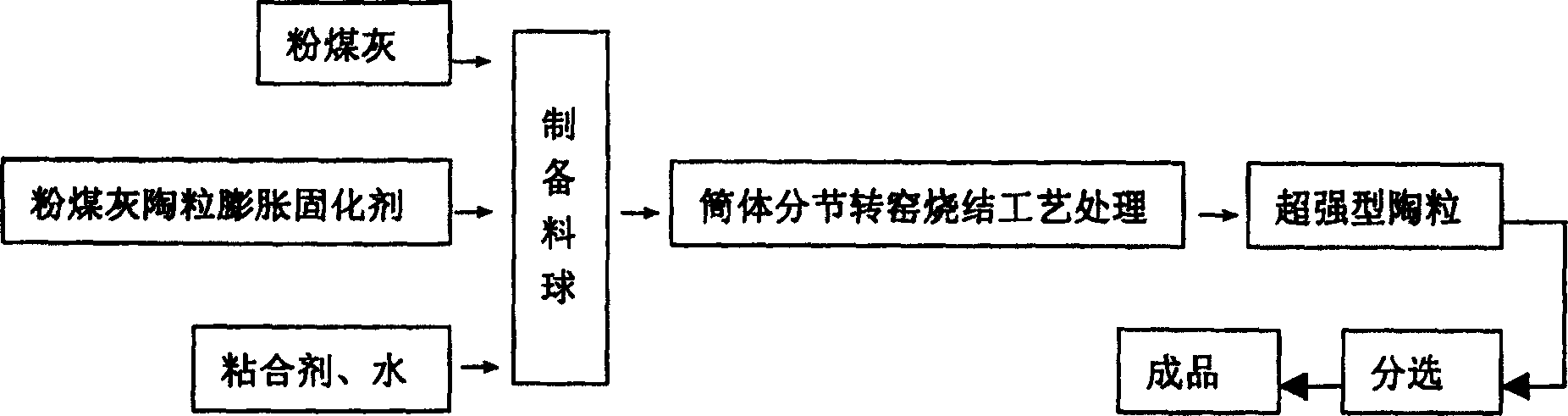

[0025] like figure 1 As shown, the production process of fly ash ceramsite includes the following procedures.

[0026] Choose 85% of fly ash and 15% of fly ash ceramsite expansion curing agent with binder to mix, add water and mix, prepare into balls, and sinter the above fly ash material balls through cylinder segmented rotary kiln, Prepare ceramsite with strength above 4.0Mpa. The "cylinder segmented rotary kiln" is my authorized patent (ZL: 01222922.9); the preparation method of the fly ash ceramsite expansion curing agent added in the sintering fly ash ceramsite process is a patent technology that I have applied for and published , its publication number is CN1288875A.

[0027] The strength of fly ash ceramsite exceeds 4.0MPa.

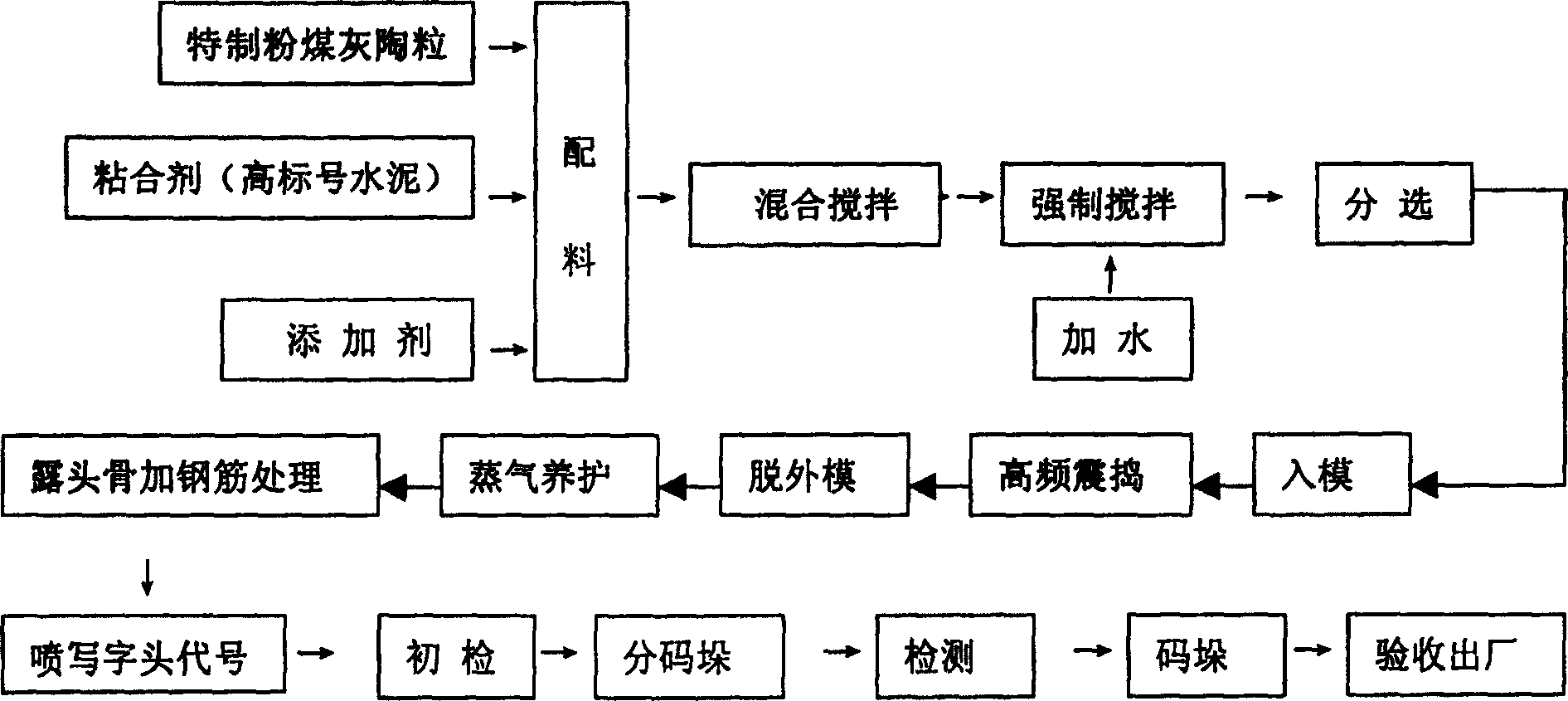

[0028] like figure 2 As shown, the sleeper material preparation method is as follows:

[0029] The first step: choose the binder, 42.5 # (equivalent to national standard 600 # The above standard) 8% of cement, 42% of fly ash ceramsite, 32% ...

Embodiment 2

[0032] like figure 1 As shown, the production process of fly ash ceramsite includes the following procedures

[0033] Choose 82% fly ash, mix with 18% fly ash ceramsite expansion curing agent with binder, mix with water, prepare into balls, and then sinter the above fly ash slurry through the cylinder segmented rotary kiln processed to prepare fly ash ceramsite with a strength exceeding 4.0Mpa. The adoption of this equipment and the preparation method of the fly ash ceramsite expansion curing agent added in the sintering fly ash ceramsite process are the same as in the first embodiment.

[0034] like figure 2 As shown, the sleeper material preparation method is as follows:

[0035] The first step: choose the binder, 42.5 # (equivalent to national standard 600 # The above standard) cement 12%, fly ash ceramsite 48%, pottery sand 28%, powdery concrete early strength agent, antifreeze agent and water mixture 12% into the concrete mixer, powdery concrete early strength agent...

Embodiment 3

[0038] like figure 1 As shown, the production process of fly ash ceramsite includes the following procedures.

[0039] Choose 80% fly ash, mix with 20% fly ash ceramsite expansion curing agent with binder, mix with water, prepare into balls, and then sinter the above fly ash material balls through the cylinder segmented rotary kiln , Prepared into fly ash ceramsite with strength exceeding 4.0Mpa. The preparation method of the cylinder segmented rotary kiln equipment and the fly ash ceramsite expansion and curing agent is the same as in the first embodiment.

[0040] like figure 2 Shown, the preparation method of its railway sleeper is as follows:

[0041] The first step: choose the binder, 42.5 # (equivalent to national standard 600 # The above standard) 10% of cement, 50% of fly ash ceramsite, 30% of pottery sand, powdery concrete early strength agent and water mixture 10% are put into the concrete mixer for batching, and the mixing ratio of powdery concrete early stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com