Flat printed element capable of infrared laser imaging and making method for said printed element and imaging method thereof

A technology of lithographic printing and imaging methods, applied in the field of preparing lithographic printing plates, wet lithographic printing plates, wet lithographic printing machines, and printing plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

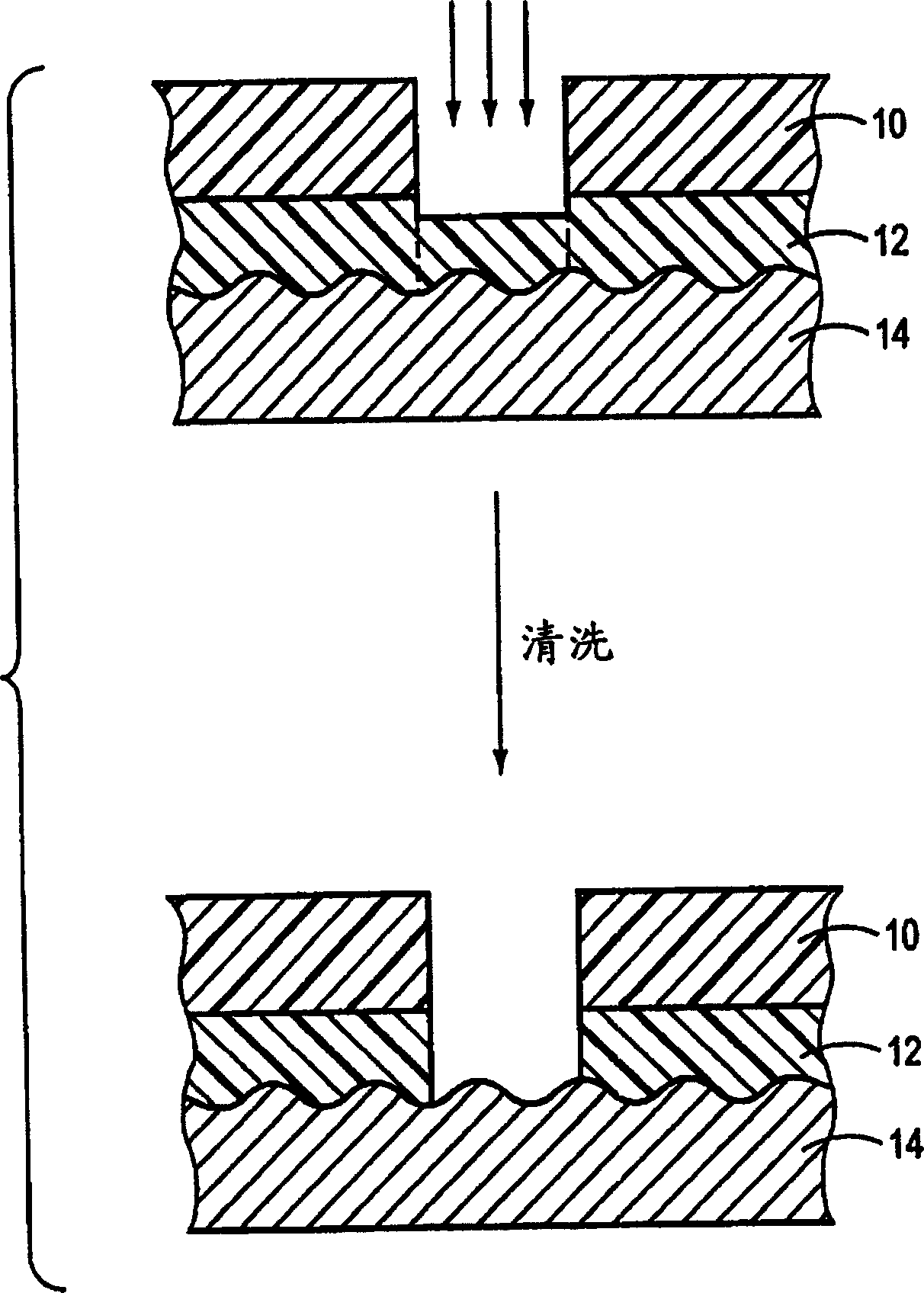

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Thus in one embodiment of the method of making a wet lithographic element of the present invention, the hydrophilic layer comprises a crosslinked polymeric reaction product of a hydrophilic polymer and a first crosslinking agent. Suitable hydrophilic polymers for crosslinking the polymeric reaction product include, but are not limited to, polyvinyl alcohol and cellulose. In a preferred embodiment, the hydrophilic polymer is polyvinyl alcohol. In one embodiment, the first crosslinking agent is a zirconium compound. In one embodiment, the first crosslinking agent is ammonium zirconyl carbonate. In a preferred embodiment, the first crosslinking agent is ammonium zirconium carbonate, and the amount of ammonium zirconium carbonate is greater than 10% by weight of polyvinyl alcohol, and more preferably 20-50% by weight of polyvinyl alcohol. %weight. In another preferred embodiment, the hydrophilic layer further comprises a second crosslinking agent. In one embodiment, the...

Embodiment 1

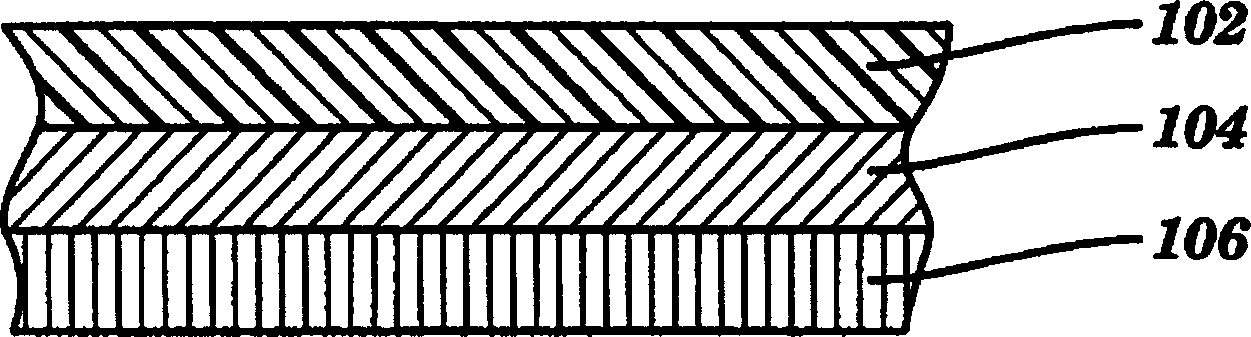

[0112] A kind of sheet base of the lithographic printing plate that has one deck hydrophilic insulation layer of the present invention, as the application figure 2Layer 104, shown in , is produced on a production line by coating a grained, anodized, and siliconized aluminum plate. The hydrophilic insulating layer has the following composition on a dry weight basis.

[0113] AIRVOL 325

4.28

BACOTE 20

1.75

0.17

TRITON X-100

0.07

BYK 333

0.10

[0114] AIRVOL 325 is a highly hydrolyzed grade of polyvinyl alcohol manufactured by Air Products & Chemical, Inc. BACOTE 20 is a Magesium Elektron, Inc. of Flemington, NJ containing 20% ZrO 2 A stable alkaline aqueous solution of ammonium zirconyl carbonate. TRITON X-100 is a hydrocarbon surfactant manufactured by Rohm & Haas. BYK 333 is a trademark for a silicone surfactant manufactured by Byk Chemie USA of Wallingford, CT.

[0115] The above ingredients ...

Embodiment 2

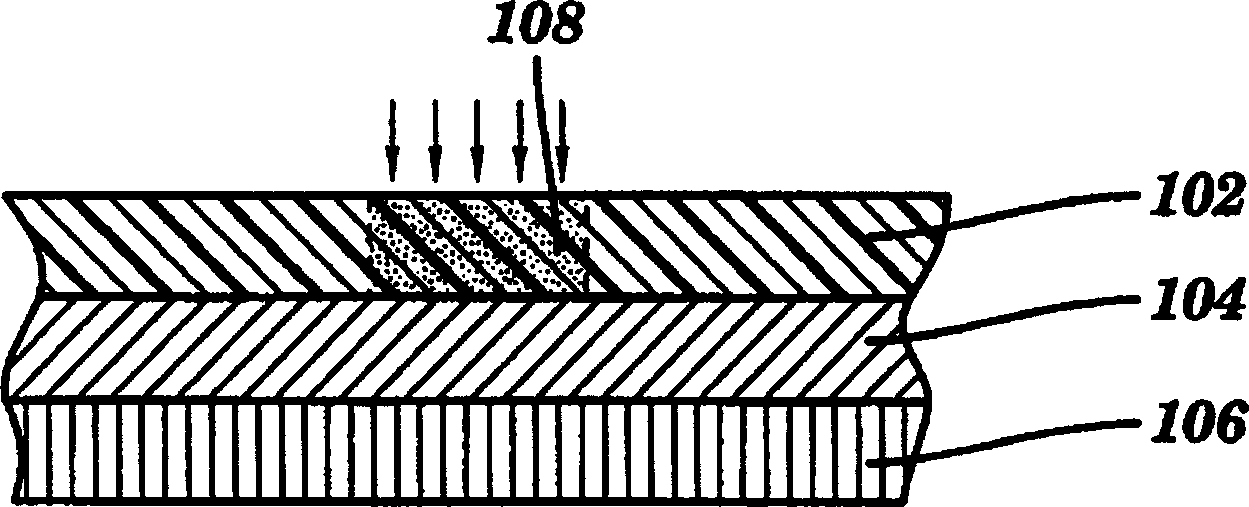

[0117] Such as figure 2 As shown, a two-layer wet lithographic printing plate was made by coating an ink-absorbing and infrared-absorbing layer of the following composition onto a hydrophilic barrier-coated aluminum support made as described in Example 1. Example 2A is a comparative example representing a wet lithographic printing plate imaged only by an ablative imaging process. Examples 2B to 2F are examples of lithographic printing plates of the present invention.

[0118] 2A

2B

2C

2D

2E

2F

AIRVOL A325

25.3

14.3

12.7

14.0

6.9

6.2

CYMEL 303

4.3

0.6

0.6

2.0

1.0

0.9

WITCOBOND 240

0.0

0.0

12.7

4.1

2.0

1.8

JONCRYL 540

0.0

0.0

0.0

0.0

50.6

45.5

Binder Subtotal

29.6

14.9

26.0

20.1

60.5

54.4

BONJET CW-1

53.1

6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com