Growth method of high-quality and large-size silicon carbide (SiC) crystal

A technology of crystal growth and silicon carbide, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of seed crystal ablation, plane hexagonal cavity, etc., to ensure full utilization, avoid seed crystal ablation, quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

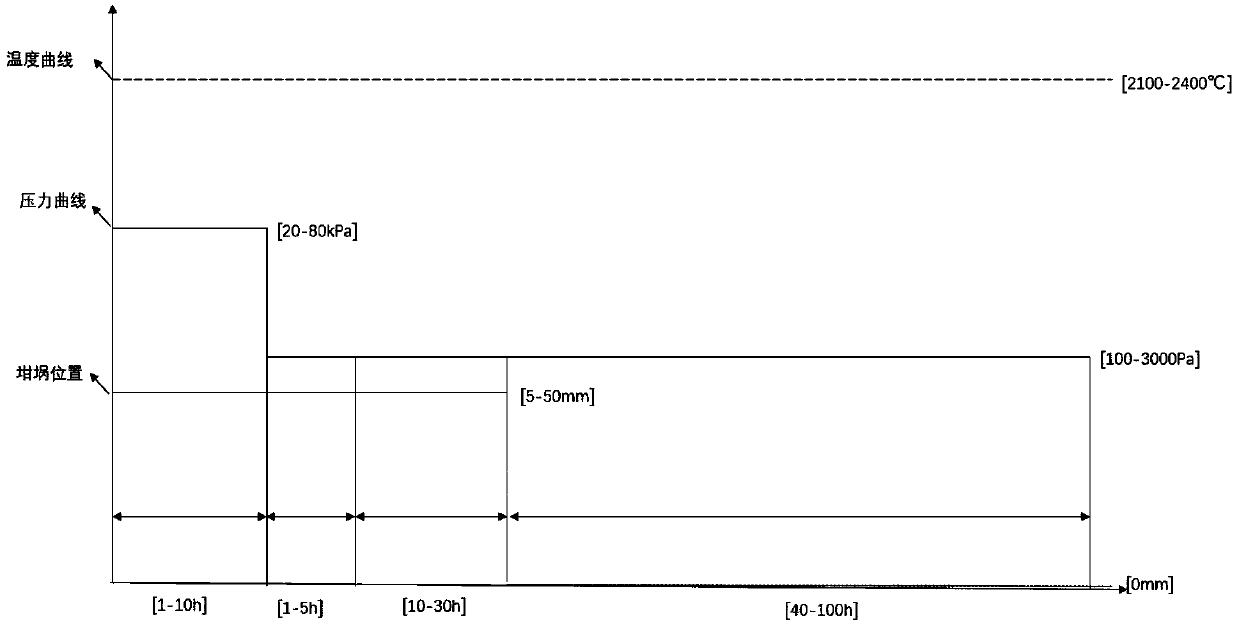

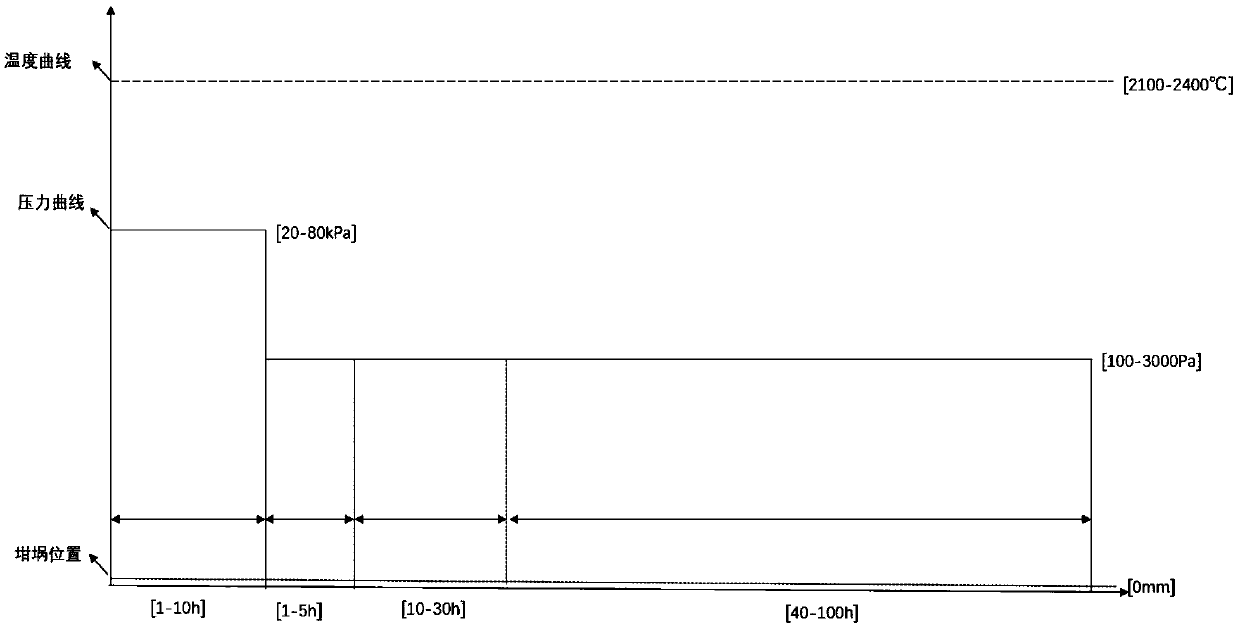

example 1

[0032] A piece of 4H-SiC seed crystal is used, and the C surface is used as the crystal growth surface, and it is bonded to the graphite crucible cover. The bottom of the crucible is filled with enough SiC powder raw materials, and then the crucible lid with the seed crystals is placed on the top of the crucible, and after assembly, it is placed in the single crystal growth furnace. Push the crucible up 20mm at a speed of 8mm / h, evacuate the single crystal furnace until the pressure is less than 10Pa, and perform the following processes in sequence: (1) Inflate the growth furnace with a mixture of argon and nitrogen until the pressure reaches 30kPa, Keep the pressure constant, use medium-frequency induction heating to increase the temperature, set the temperature of the raw material to 2200-2300℃, keep it for 3h after the temperature is reached, and then keep the temperature in the furnace unchanged; (2) Reduce the pressure through the growth furnace pressure control system Red...

example 2

[0034] A piece of 4H-SiC seed crystal is used, and the C surface is used as the crystal growth surface, and it is bonded to the graphite crucible cover. The bottom of the crucible is filled with enough SiC powder raw materials, and then the crucible lid with the seed crystals is placed on the top of the crucible, and after assembly, it is placed in the single crystal growth furnace. Push the crucible up by 30mm at a speed of 10mm / h, evacuate the single crystal furnace until the pressure is less than 10Pa, and then perform the following processes in sequence: (1) Inflate the growth furnace with a mixture of argon and nitrogen until the pressure reaches 40kPa, Keep the pressure constant, use medium frequency induction heating to heat up, set the temperature of the raw material to 2100-2200℃, keep it for 5h after the temperature is reached, and then keep the temperature in the furnace unchanged; (2) Through the growth furnace pressure control system, the pressure Decrease to 800Pa...

example 3

[0036] A piece of 4H-SiC seed crystal is used, and the C surface is used as the crystal growth surface, and it is bonded to the graphite crucible cover. The bottom of the crucible is filled with enough SiC powder raw materials, and then the crucible lid with the seed crystals is placed on the top of the crucible, and after assembly, it is placed in the single crystal growth furnace. Push the crucible up 40mm at a speed of 12mm / h, evacuate the single crystal furnace until the pressure is less than 10Pa, and then proceed as follows: (1) Inflate the growth furnace with a mixture of argon and nitrogen until the pressure reaches 60kPa, Keep the pressure constant, use medium-frequency induction heating to increase the temperature, set the temperature of the raw material to 2200-2300℃, keep it for 6h after the temperature is reached, and then keep the temperature in the furnace unchanged; (2) Through the growth furnace pressure control system, the pressure Decrease to 1000Pa and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com