Low-temp. solvent evaporation induced crystallization process for preparing crystallized titanium dioxide photocatalyst

A technology of titanium dioxide and photocatalyst, applied in catalyst activation/preparation, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of drop, particle growth, specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for preparing nanocrystalline titanium dioxide powder photocatalyst by low-temperature solvent evaporation-induced crystallization is as follows: using isopropyl titanate as the titanium source, add 0.063M isopropyl titanate organic solvent dropwise to 113 ml of distilled water for hydrolysis while stirring vigorously , The time is 1 hour, the molar ratio of water to isopropyl titanate is 100:1, the titania sol sample obtained by hydrolysis is placed and aged at 25°C for 24 hours, then the sample is placed in an oven and gradually evaporated at 100°C Water and organic solvent to obtain titanium dioxide xerogel powder. Finally, the dry gel is ground finely to obtain a titanium dioxide powder photocatalyst.

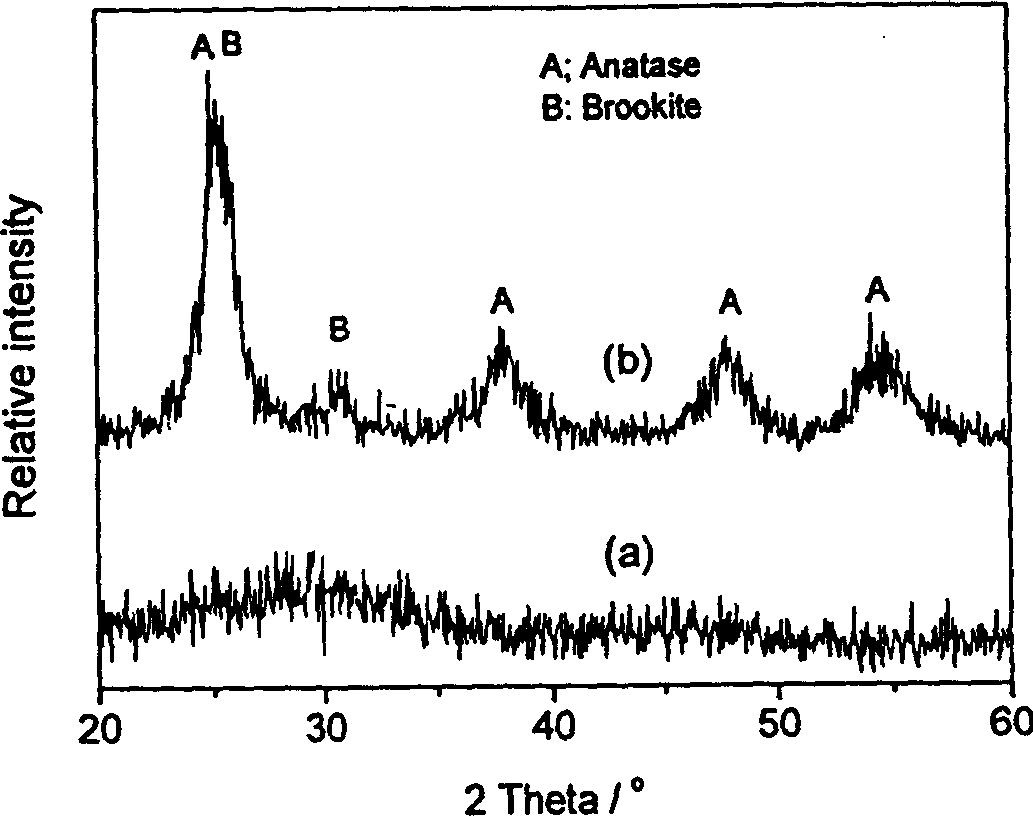

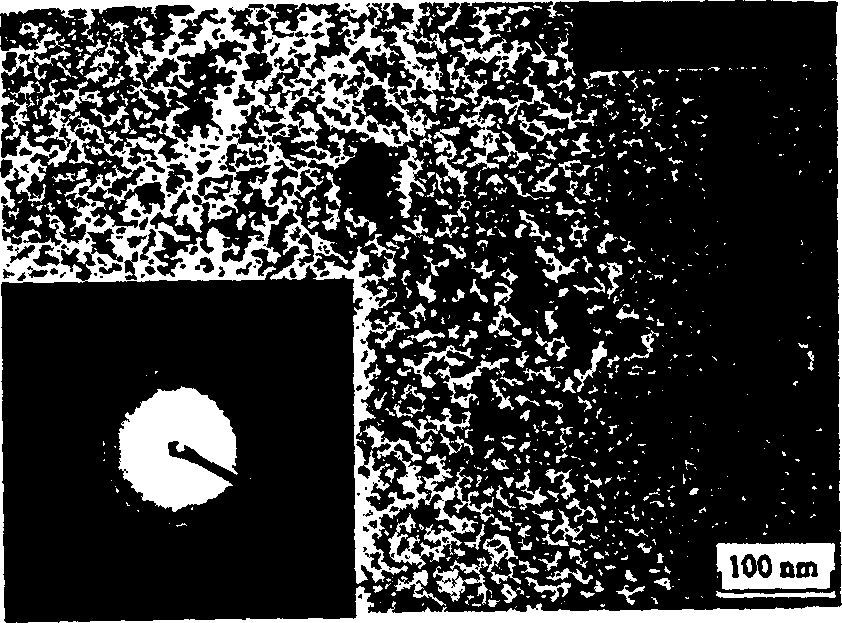

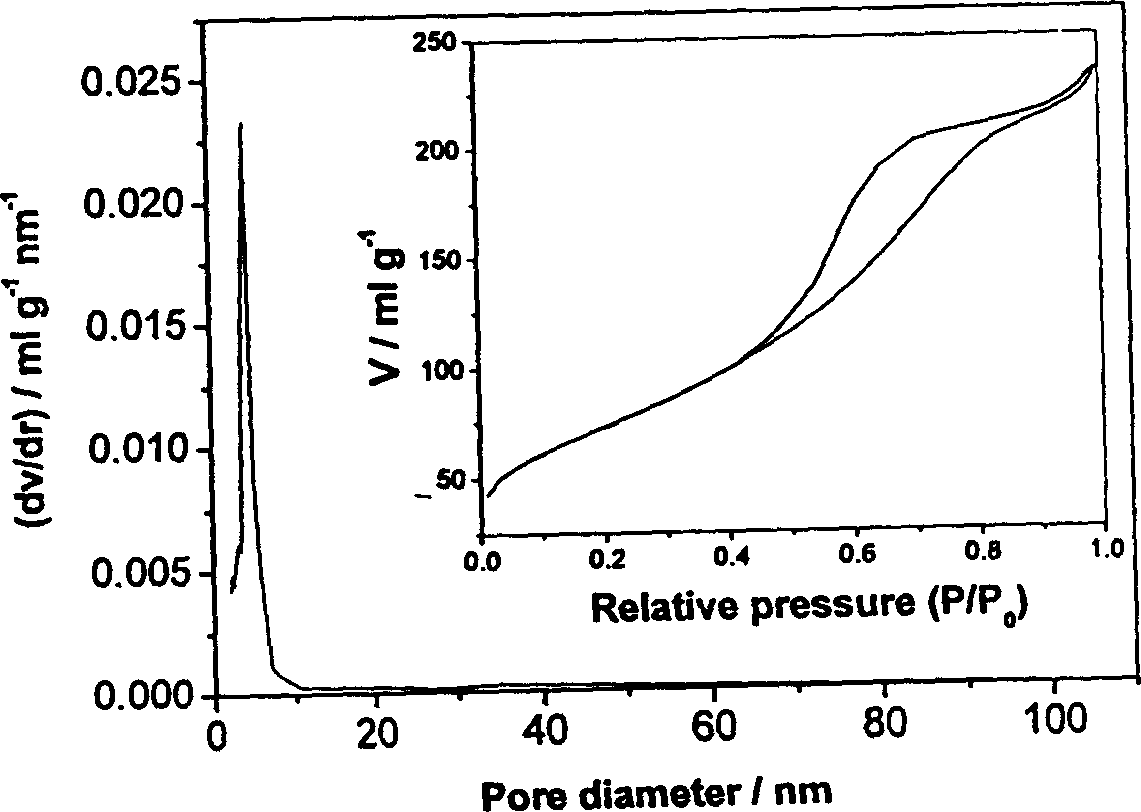

[0022] figure 1 Shows the XRD patterns of titanium dioxide wet gel and dry gel, from figure 1 It can be seen that the titanium dioxide wet gel obtained by the direct hydrolysis of isopropyl titanate is in an amorphous state, however, the titanium dioxide dr...

Embodiment 2

[0027] Except that the titanium source used is n-butyl titanate, other reaction conditions such as the concentration of the titanium source, the amount of solvent water, the temperature and time of hydrolysis, aging and solvent evaporation are exactly the same as in Example 1. The obtained titanium dioxide The phase structure and composition of the powder photocatalyst are: anatase occupies 67%, and the brookite phase occupies 33%. According to the Scherrer formula, the grain sizes of the anatase and brookite phases are calculated to be 5.0 and 3.1 nm, respectively. The titanium dioxide photocatalyst prepared with n-butyl titanate as the titanium source also shows very high photocatalytic activity, and its apparent rate constant is 3.72×10 -3 (min -1 ), and the photocatalytic degradation rate constant of Degussa P25 is 4.19×10 -3 (min -1 ) Close.

Embodiment 3

[0029] The temperature at which the solvent evaporates is 140°C. Except for the different evaporation temperature of the solvent, other reaction conditions such as the concentration of the titanium source, the concentration of the titanium source, the amount of solvent water, the temperature and time of hydrolysis and aging, and the time of solvent evaporation are exactly the same as in Example 1. The titanium dioxide powder photocatalyst shows higher photocatalytic activity, and its apparent rate constant is 3.91×10 -3 (min -1 ). This may be due to the better crystallinity of the prepared titanium dioxide powder photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com