Variable capacitor

A capacitor and variable technology, applied in the direction of variable capacitors, capacitors, capacitors that change the effective area of electrodes, etc., can solve the problems of high processing cost, affecting electrical conductivity, and increasing the cost of variable capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

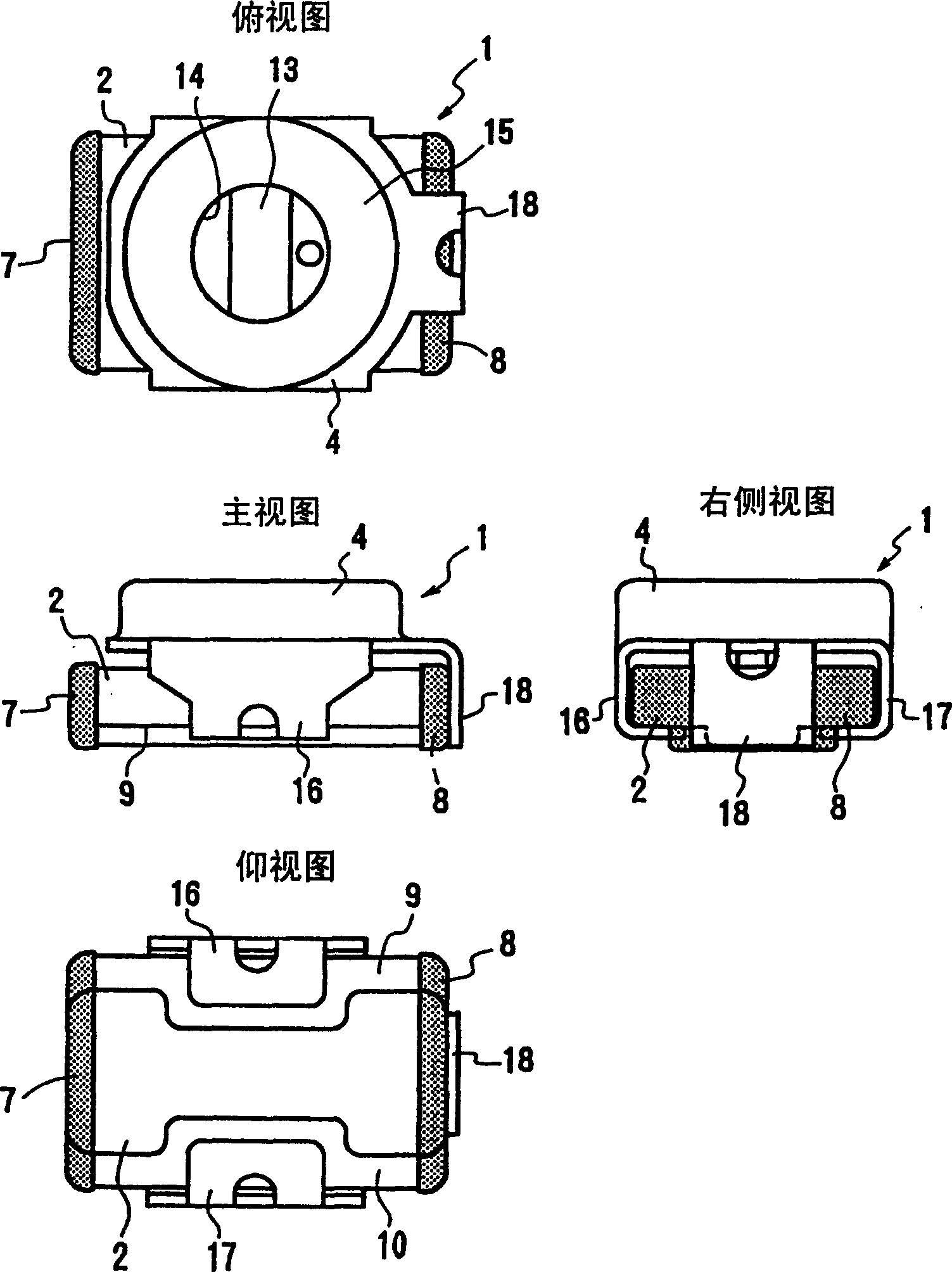

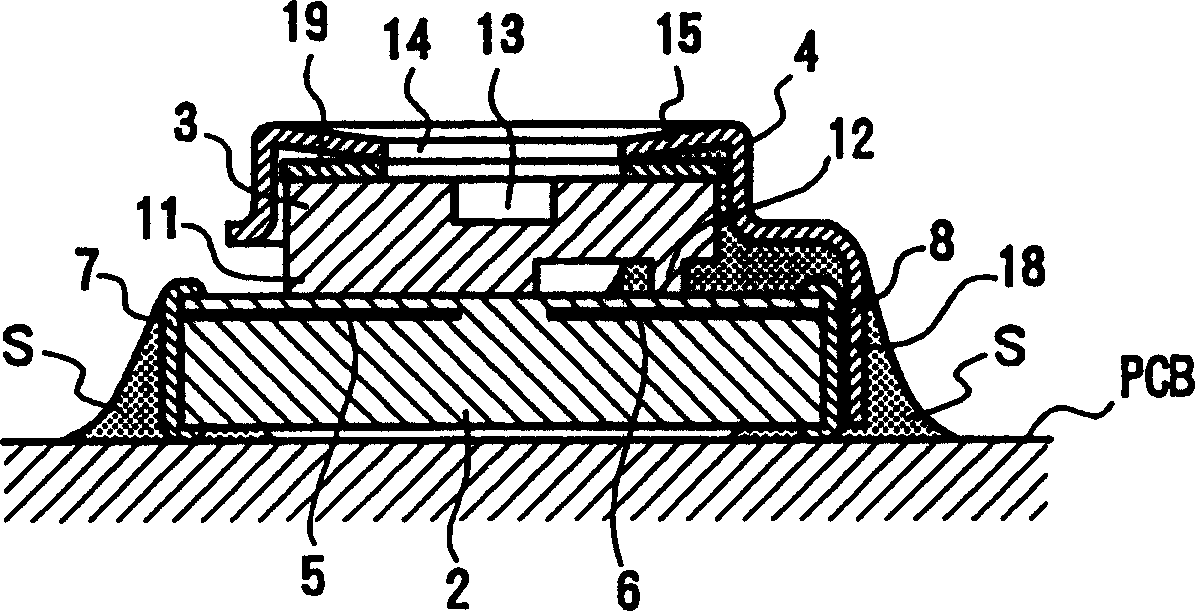

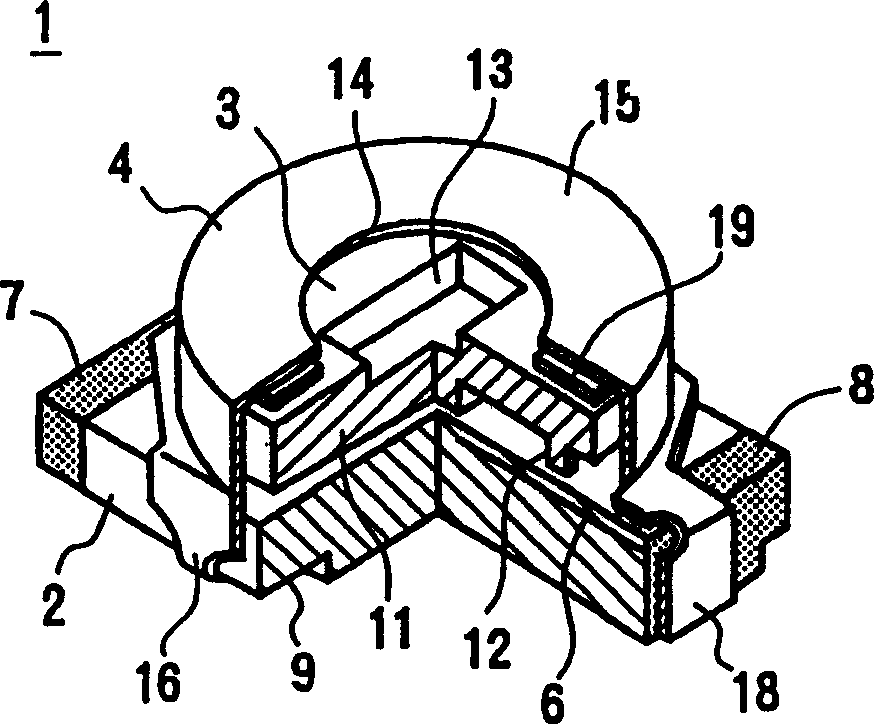

[0036] Figure 4 and Figure 5 Embodiment 1 of the variable capacitor 1' of the present invention is shown. The basic structure and reference of this embodiment figure 1 and figure 2 The variable capacitor 1 described is the same, and the same parts as the variable capacitor 1 are also denoted by the same symbols, so repeated description is omitted.

[0037] The cover 4 is made of spring-elastic conductive metal such as stainless steel or phosphor bronze. The entire surface of the cover 4 is surface treated (for example, gold-plated, silver-plated, tin-plated) to reduce contact resistance and improve solder wetting and adsorption performance. It is desirable that the surface is tinned as a whole.

[0038] On the way of the lid joint 18 integrally formed with the lid 4 , an outwardly expanding expansion protrusion 18 a is formed, and a liquid storage portion 20 is formed between the expansion protrusion 18 a and the stator 2 . The expansion protrusion 18 a in this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com