Method and apparatus for preparing fresh water from sea water

A seawater and freshwater technology, applied in heating water/sewage treatment and other directions, can solve the problems of inability to produce salt, no economic benefits, and high cost of freshwater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

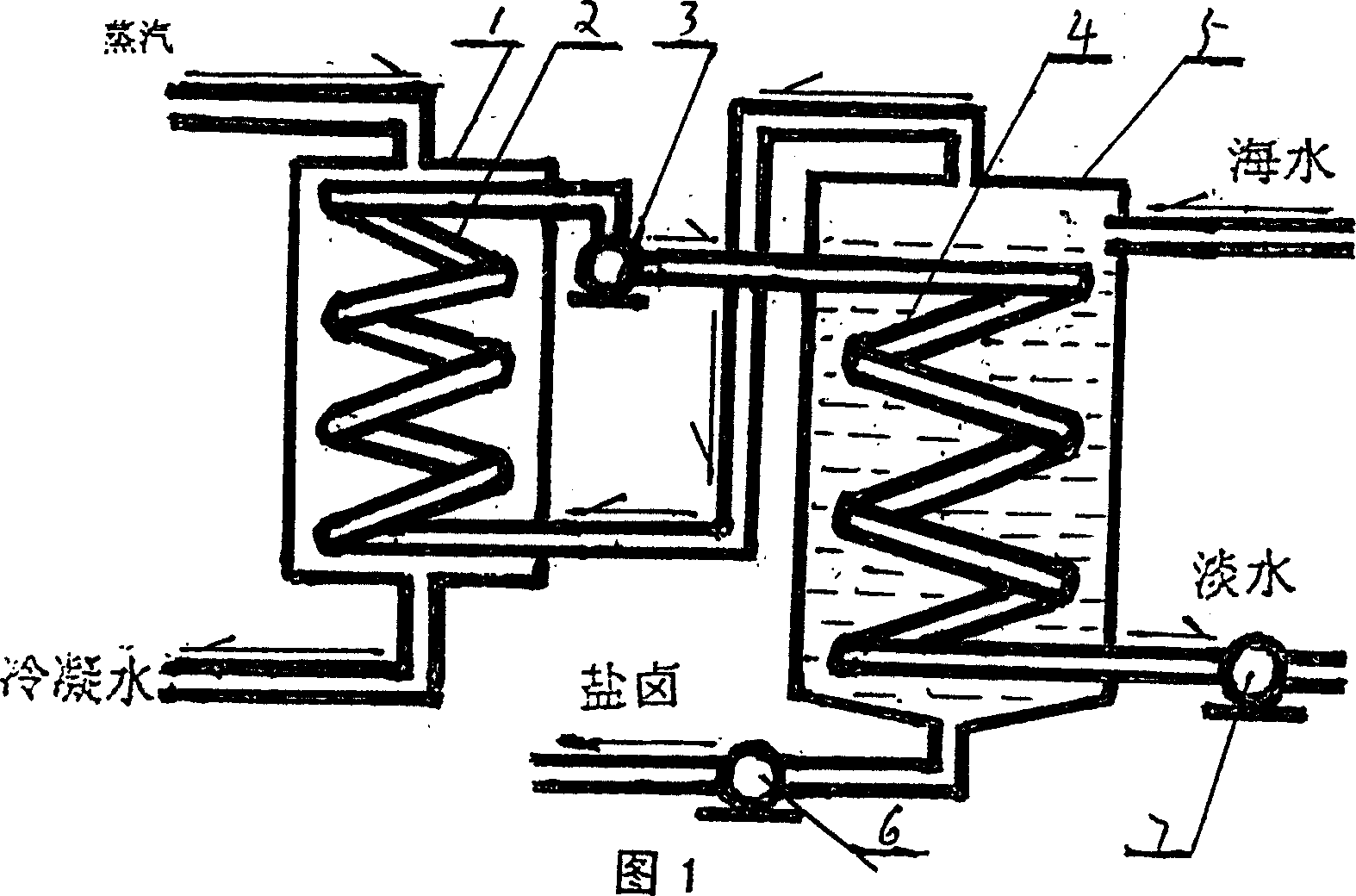

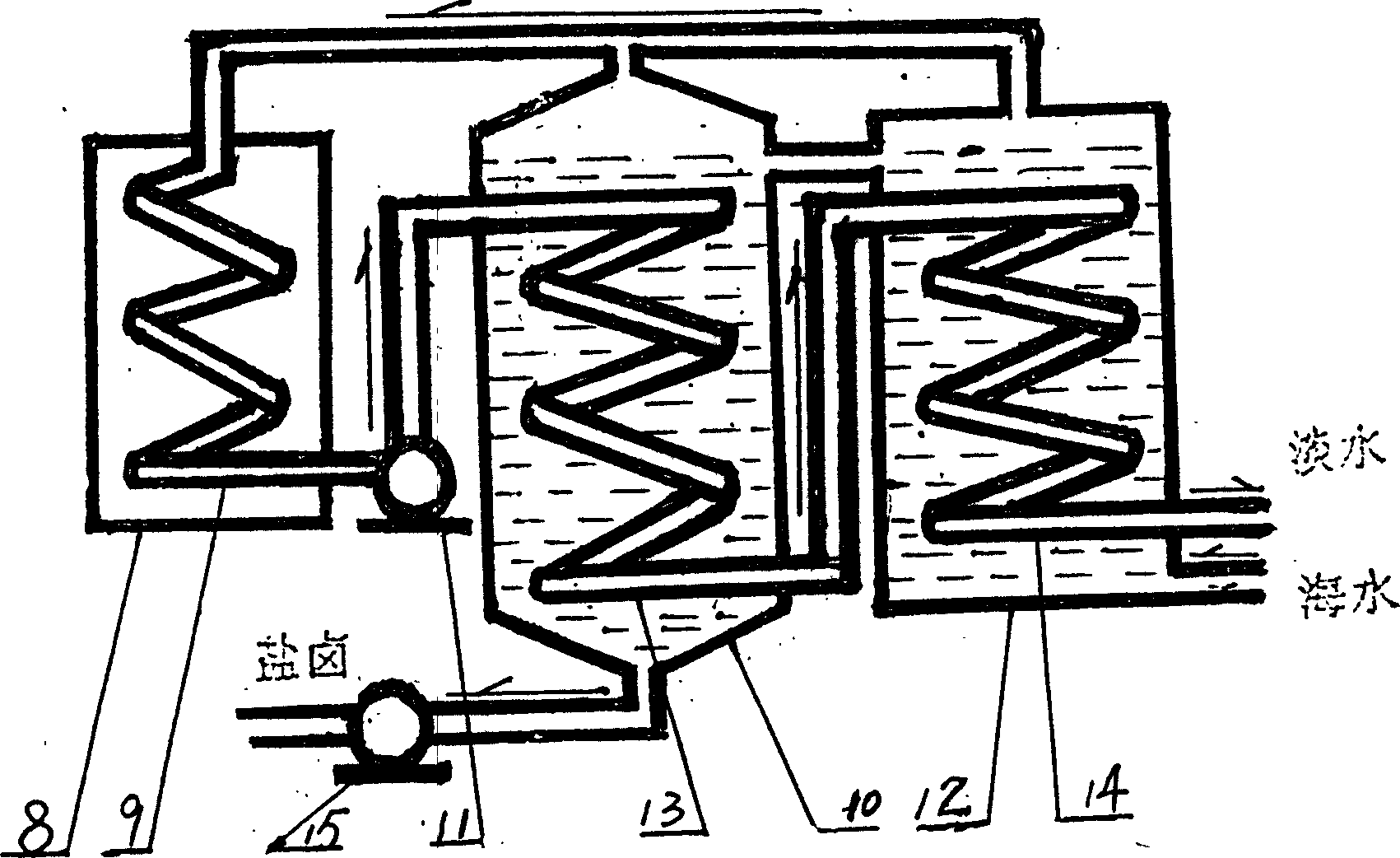

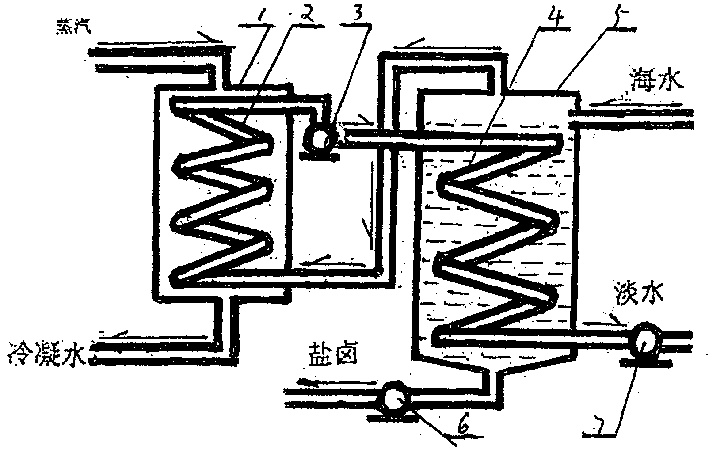

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0015] In Fig. 1, the device diagram of the indirect heating distillation system using the normal temperature and reduced pressure distillation method is composed of an evaporation chamber 5, a condensation pipe 4, a high pressure pump 6, a water pump 7, a gas compressor 3, a heat exchanger 1, and a heating pipe 2. The evaporation chamber 5 is a hollow cylinder, and the inside is filled with spiral condenser pipes 4 made of a copper-nickel alloy. The water outlet at the lower part of the condensation pipe 4 communicates with the water pump 7. There is a steam outlet on the top of the evaporation chamber 5, which is connected to the steam inlet end of the heating pipe 2 in the heat exchanger 1 through a pipe. The heating pipe 2 is made of ordinary stainless steel. The steam outlet communicates with the steam inlet of the gas compressor 3 . The lower discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com