Methane-propane united liquefaction and gasification device

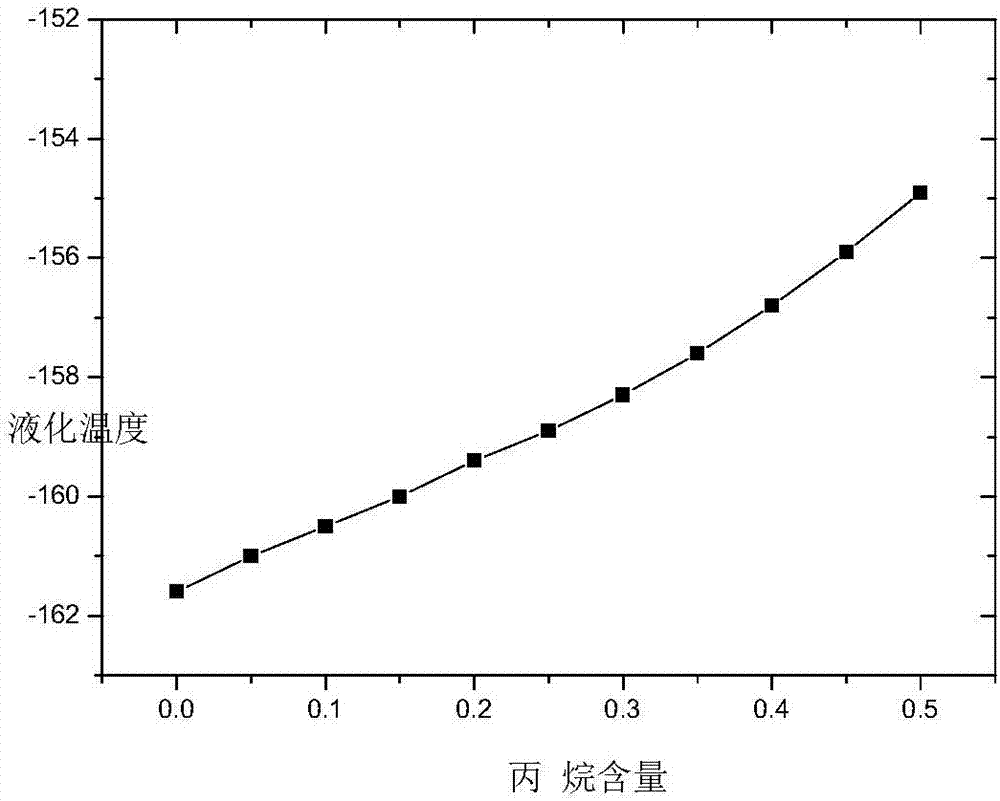

A liquefaction device, propane technology, applied in the directions of liquefaction, refrigeration and liquefaction, equipment loaded into pressure vessels, etc., can solve the problems of low boiling point of methane and complex liquefaction process, so as to improve the liquefaction temperature, improve the storage and transportation temperature, reduce the The effect of cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

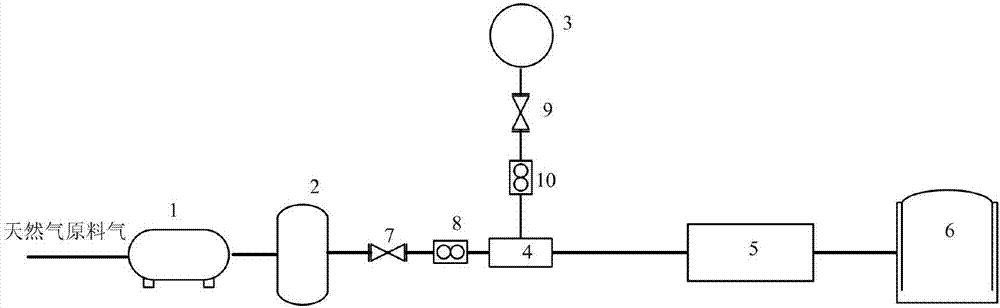

[0018] Such as figure 1 As shown, a methane-propane combined liquefaction device mainly includes: dehydration module 1, purification module 2, propane supply module 3, gas mixer 4, refrigeration module 5, liquefied gas production storage tank 6, dehydration module 1, purification module 2 1. The gas mixer 4 is connected sequentially through pipelines, the propane supply module 3 is also connected with the gas mixer 4 through pipelines, the outlet of the gas mixer 4 is connected with the refrigeration module 5 through pipelines, and the outlet of the refrigeration module 5 is connected with the inlet of the liquefied gas production storage tank 6 connected.

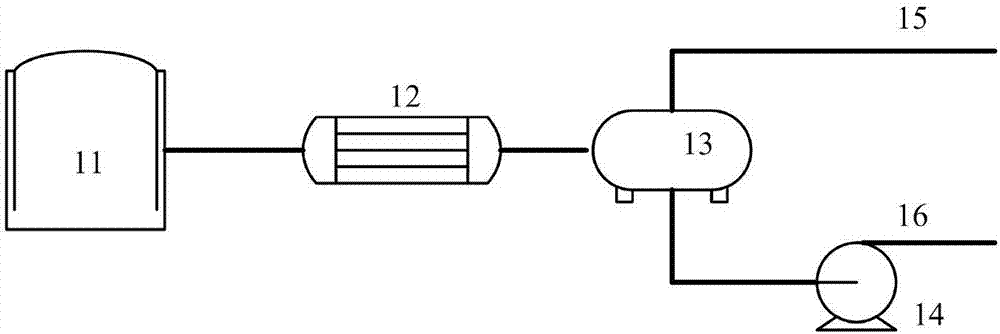

[0019] A methane-propane combined vaporization device, mainly including: liquefied gas user storage tank 11, vaporizer 12, gas-liquid separator 13 and propane unloading pump 14, liquefied gas user storage tank 11, vaporizer 12, gas-liquid separator 13 through pipelines Connected in sequence, the top of the gas-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com