Tubular welding wire for austenite stainless steel welding

A technology of austenitic stainless steel and stainless steel, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of easy flow of welding metal, deterioration of workability, poor appearance, etc., and achieve the improvement of welding metal dripping Phenomenon, reduction of smoke generation, and effects of suppressing bending and hot cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

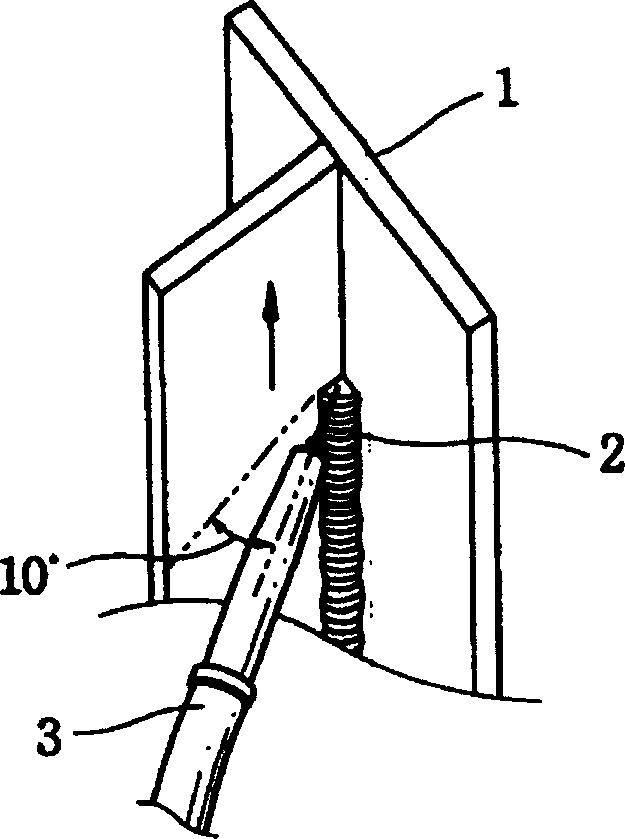

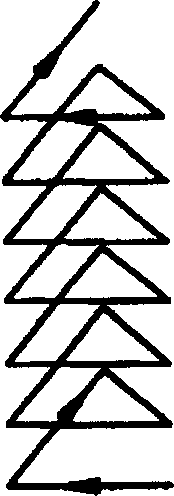

Image

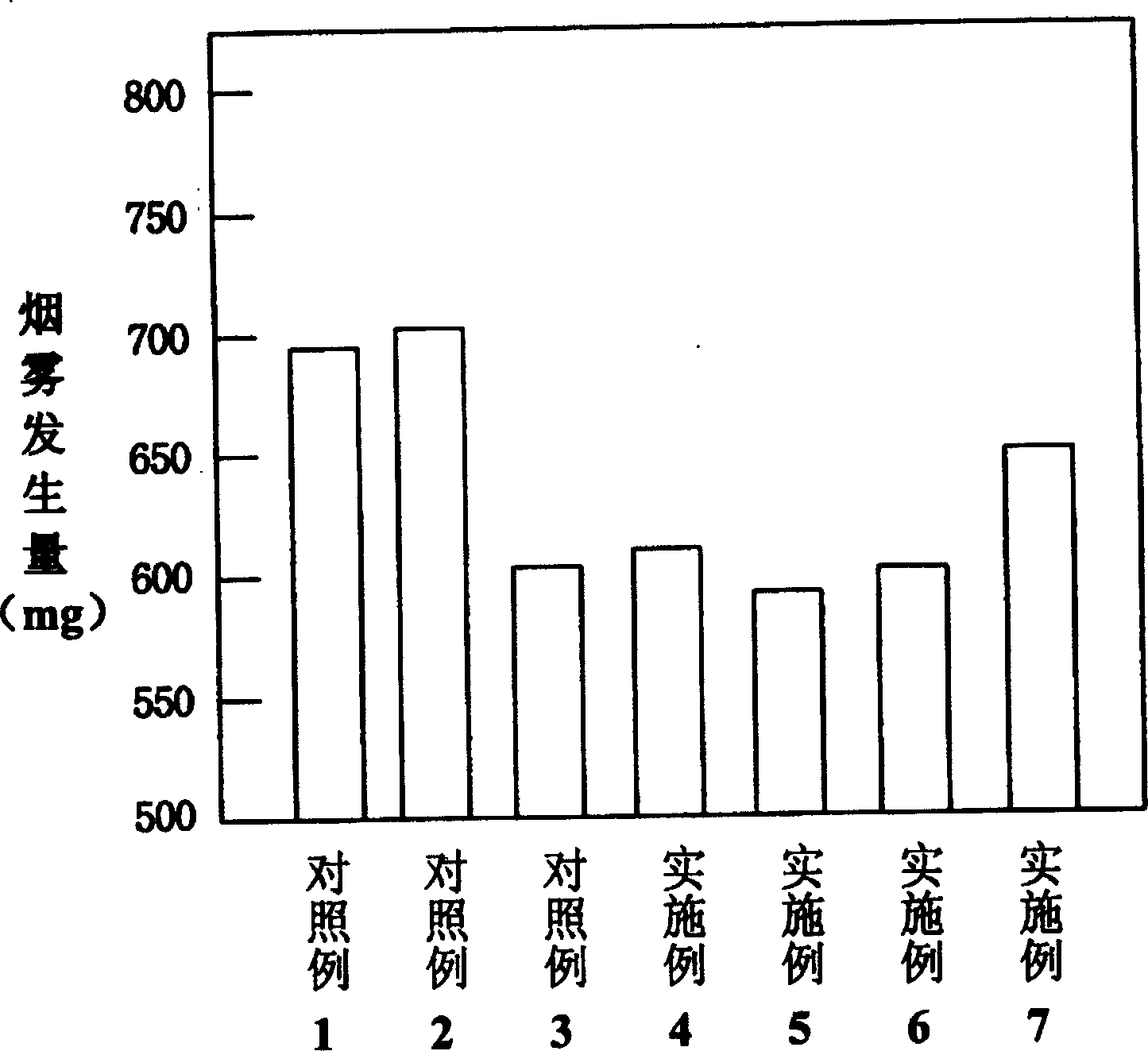

Examples

Embodiment Construction

[0025] The welding wire with the above composition is used for welding according to the following conditions in Table 2, and Table 3 shows the composition and mechanical properties of each weld metal.

[0026] base material

Welding current

welding voltage

welding speed

masking gas

SUS 304, thickness 6 t

210A

30V

25cm / min

CO 2 the gas

[0027] Classification

Chemical composition of weld metal (wt%)

the surface

to bend

test

in

to bend

test

hot crack

test

C

Si

mn

Ni

Cr

Mo

P

S

Comparative example

1

0.037

0.60

1.34

9.96

19.50

0.05

0.016

0.009

good

2.5

6.5

2

0.041

0.58

1.26

9.52

19.38

0.05

0.018

0.010

good

3

8

Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com