Method for mfg. microstructure resonance beam pressure sensor using SiNx as beam

A technology of a pressure sensor and a manufacturing method, applied in directions such as measuring fluid pressure, using mechanical devices to transmit sensing components, and measuring fluid pressure through mechanical components, can solve problems such as difficulty in controlling dimensional accuracy, reducing device performance, and high device cost, and achieve Good machining performance, reduced device cost, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

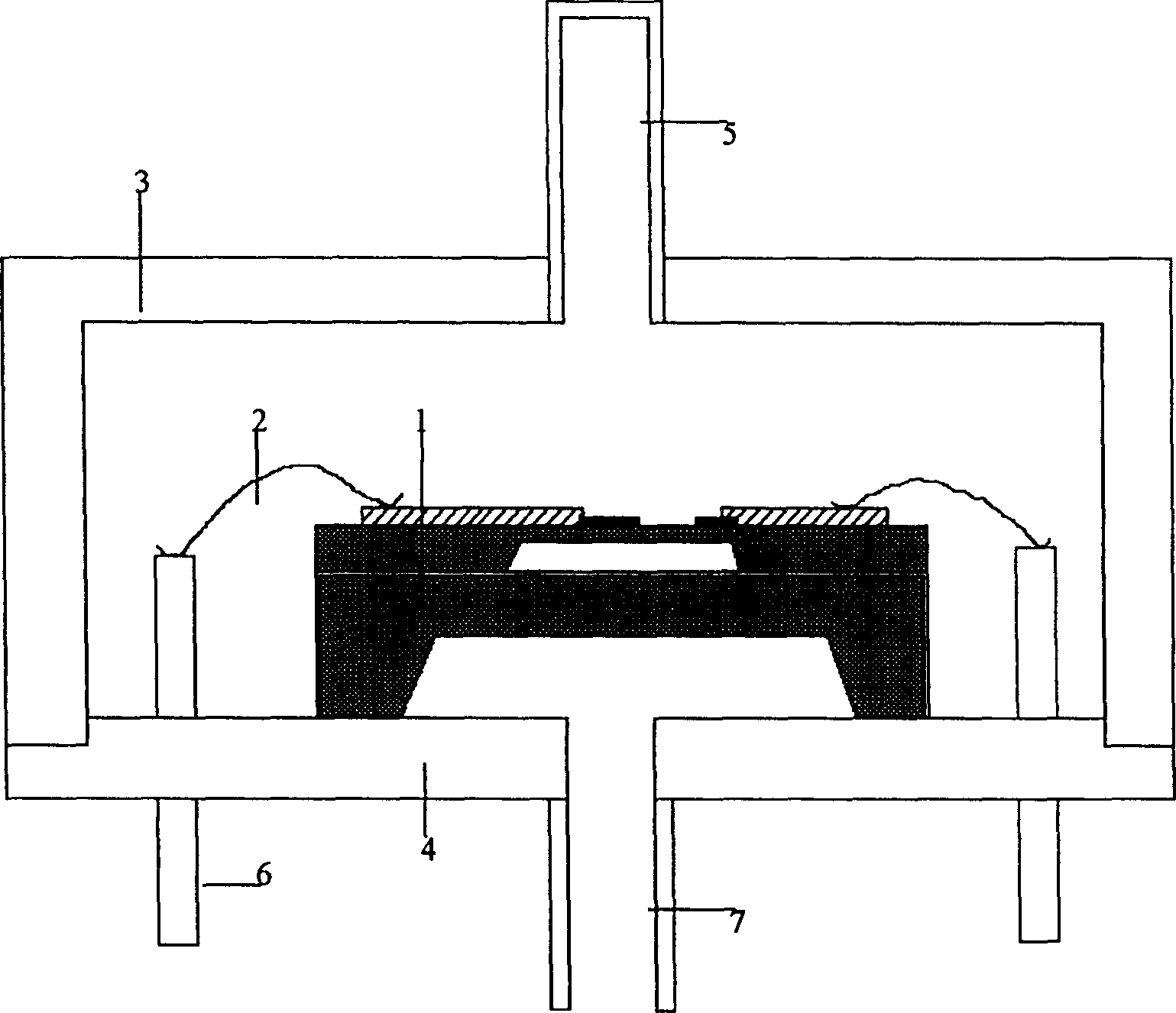

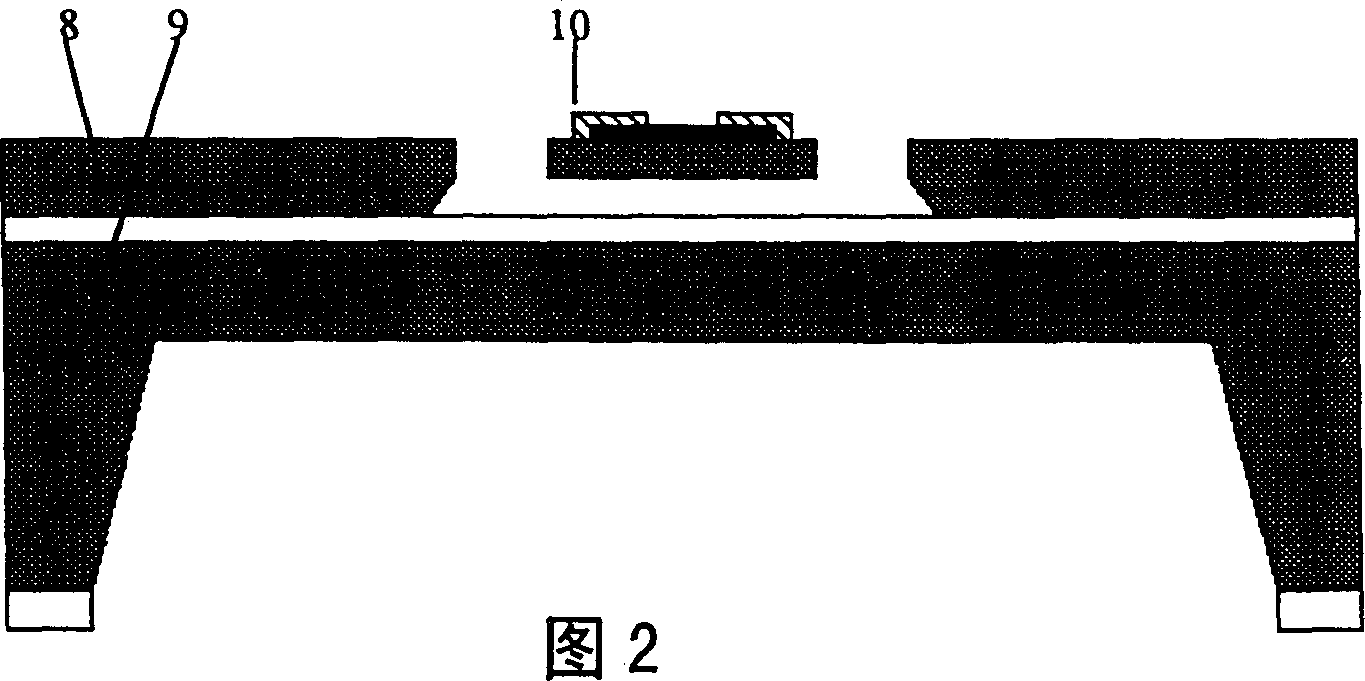

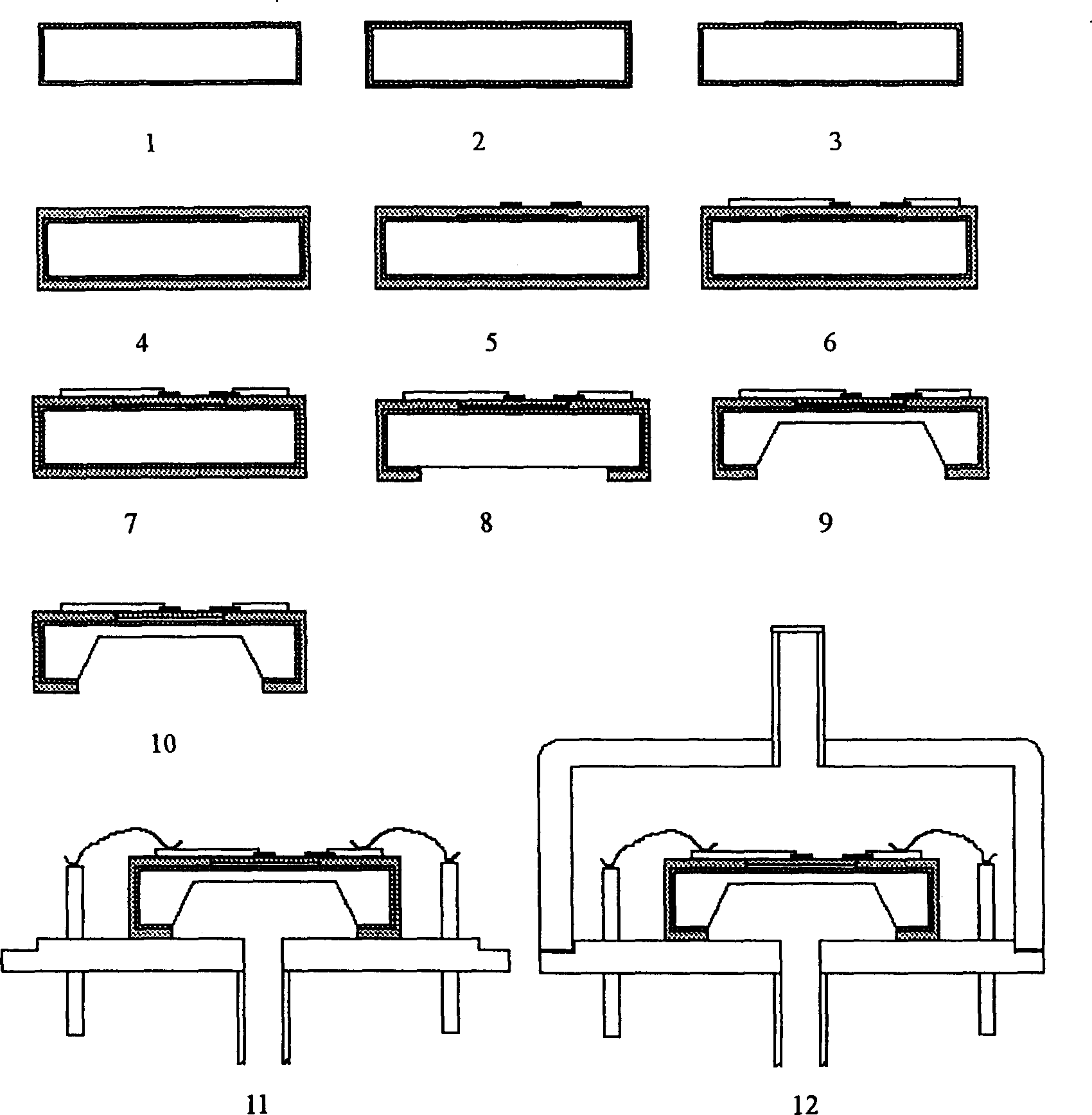

[0028] From Figure 5 , Figure 6 and figure 1 , the comparison of the resonant beam pressure sensor chip in Figure 2, we can clearly see that the composite beam membrane SiN x The microstructure resonant beam pressure sensor is different from the silicon microstructure resonant beam pressure sensor, wherein the value of x is 0.3-0.8. The chip of the silicon microstructure resonant beam pressure sensor is composed of two silicon chips that have been three-dimensionally processed, and the composite beam membrane SiN x The microstructure resonant beam pressure sensor chip is just a three-dimensional processed silicon chip.

[0029] With ultra-thick low stress SiN x The core of the resonant beam pressure sensor is the composite beam-membrane microstructure of the beam. The core of the pressure sensor is the resonator, which contains the excitation unit that makes the beam generate forced vibration and the vibration pickup unit that detects the resonance signal. The excitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com